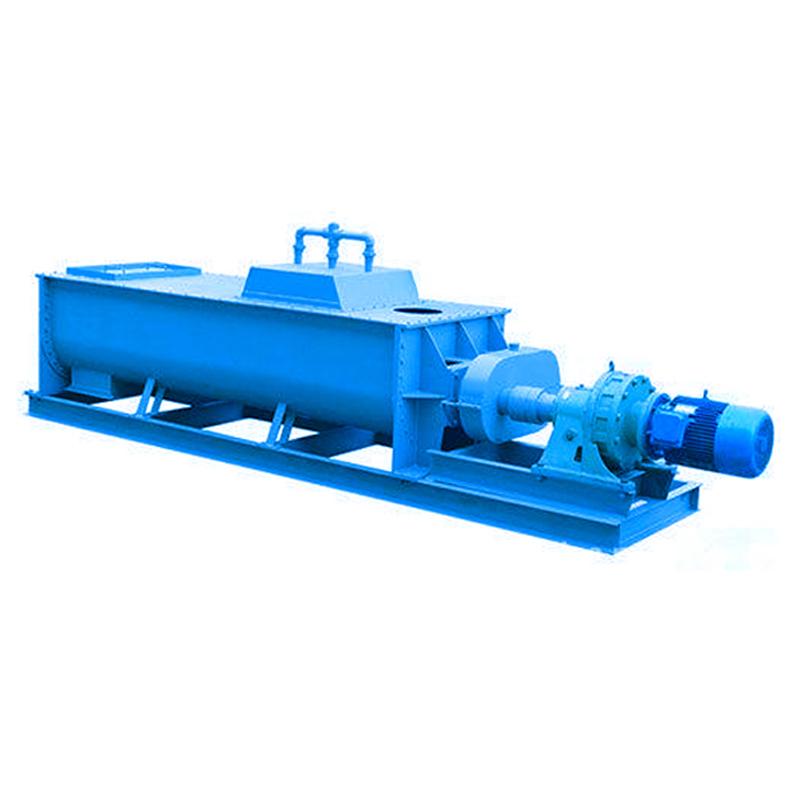

The biaxial mixer uses two symmetric screw shafts to rotate synchronously. It transports dry ash and other powdered materials while mixing with water to evenly wet the dry ash powder materials so that the humidified materials do not get dry ash and will not leak out. The purpose of water droplets, so as to facilitate the transport of wet ash loading or transfer to other conveying equipment. It is mainly applied to the occasions where coal ash or similar materials are used for humidification and loading of vehicles in thermal power plants and mines.

Double Axis Dust Humidifier Performance characteristics:

The biaxial mixer is mainly composed of a housing, screw shaft assembly, driving device, piping, cover plate, chain cover and other components. The specific structural performance characteristics are as follows:

-

The shell is mainly composed of sheet metal and steel. It is welded and formed in the factory, and is assembled with other parts. It is the support of the double shaft mixer. The shell is tightly sealed and there will be no fly ash or ash leakage.

-

The screw shaft assembly is the main component of the double-shaft mixer. Its components mainly include left and right screw shafts, bearing seats, bearing bushes, bearing covers, gears, sprocket wheels, oil cups, blades and other components.

-

The water-adjusting wet pipe is mainly composed of a nozzle, a joint, and a nozzle. The nozzle adopts stainless steel atomizing cone nozzle, which is arranged above the inside of the mixer shell and is axially arranged along the direction of the screw axis to form a curtain to facilitate the humidification of the material. The nozzle structure is simple, easy to replace, stainless steel, anti-corrosion and durable. The moisture content of the wet ash can be adjusted by operating a manual regulating valve on the water supply pipe.

-

The cover plate mainly includes a left cover, a middle cover, a right cover, a hole cover, and a manhole cover. There are six manholes on both sides of the biaxial mixer to facilitate the operator's usual maintenance and repair.