· Effect of baghouse cages size: In the geometry of the filter bag cage, the diameter of the dust removal frame, the gas inlet, and the shape and size of the exhaust pipe are the most important influencing factors.

· The influence of gas parameters on the performance of baghouse filter cages : including the influence of gas flow rate, the influence of gas dust concentration, the influence of gas moisture content, the influence of gas density, viscosity, pressure, and temperature.

· The effect of physical properties of dust on bag supporting cages.

· The effect of dust on the inner wall roughness of the framework: Concentration of dust particles near the wall surface will cause swirling due to the rough surface, causing some dust particles to be thrown into the rising air stream and entering the exhaust pipe, which reduces the dust removal efficiency.

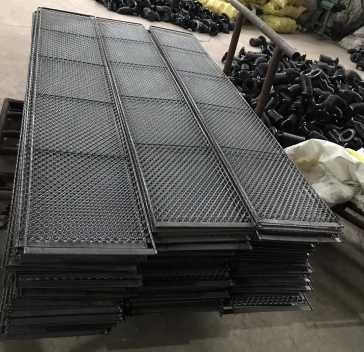

The dust baghouse cage requires a uniform distribution of supporting rings and longitudinal bars, and should have sufficient strength and rigidity to withstand the gas pressure of the filter bag in the state of filtering and cleaning, and can prevent the normal transportation and installation process from occurring. Damage and deformation caused by impact.

· Filter bag cage all welding points should be welded firmly does not allow off welding, welding and missed welding.

· The surface of the filter bag cage and the filter bag should be smooth, do not allow welding, uneven and burr.

· The tension spring type skeleton should have enough turns and elasticity, and the distance should be uniform after pulling open.

· The surface of the filter bag cage must be treated with anti-corrosion, according to different needs of the plating, spray or paint, such as for high temperature, the corrosion should be clear to meet the use of temperature requirements.

· Dust bag cage verticality 6M positive and negative 1mm.

· Dust bag cage has an integral, sub-section of two or three sections.

· Dust bag cage length of more than 3 meters wearing a steel molding pipe.

· Dust bag cage galvanized, spray, silicone processing.

As one of the mature filter bag cage manufacturers, Senotay has different types of bag house for sale. Contact us now to get more about our bag supporting cages.

Our bag house supporting cages are manufactured by Senotay's highly skilled workers and are available in a wide range of options.

Senotay manufactures dust collector filter bags and cages from carbon steel, galvanized steel and stainless steel, with the option to apply a specialized epoxy after fabrication to prevent chemical corrosion and extend service life.

As a professional filter cage manufacturer, we use only precision stamped or spun collars, pans and venturi to produce our highest quality bag filter supporting cages.

If you have special filter dust bag cage requirements, contact us now. In most cases, we can customize a filter bag cage to fulfill your needs.

Industry Leading Filter Cage Manufacturer

We are a leading bag supporting cages supplier in China. As a professional filter cage manufacturer, the company has 20 years of design, manufacturing experience and advanced automatic production lines. Products are sold in more than 100 countries around the world.

We have many kinds of products for sale, such as high-quality bag house cages. According to the different needs of customers, we can customize and process dust collector bags and cages to meet customers' needs. Among all the parts of the filter bag cages, there is one part called the bag cages. Bag cages are a very important part of the bag filter, and its quality will directly affect the service life of the baghouse dust filter cage.

The bag cages are composed of multiple longitudinal carbon steel wires and multiple transverse wire rings welded. The upper part of the bag cage is designed with a venturi tube, which can effectively protect the dust filter bag from being damaged by the impact of high-pressure airflow. According to the diameter of the bag cage, the number of longitudinal steel wires is generally divided into 8, 10, 12, 16, 24 and other different numbers. Different diameters of steel wire are selected according to the length of the bag cage. The diameter of the steel wire is generally 3.0 mm, 3.2 mm, 3.5 mm, 3.8 mm and 4.0 mm.

According to the temperature of the filtered flue gas, we use electrostatic spraying, galvanizing treatment and high-temperature silicone spraying on the surface of the bag cage. In terms of production and processing, we have introduced advanced bag cage welding equipment to ensure that the error of the bag cage has reached a minimum value. There are many kinds of our bag cage structures, which are divided into carbon steel and stainless steel according to the material, and divided into round, flat, trapezoidal, spring type, pleated type and so on according to the shape.

We will take it seriously when serving every customer, and we welcome friends from all over the world to visit our company.