The Rotary Valve: A Precision Gatekeeper for Industry

A rotary valve is a fundamental mechanical device used to control the flow of dry, bulk materials like powder, granules, or pellets. Its primary role is to function as a precision gatekeeper, consistently discharging a set amount of material from one chamber to another.

More importantly, it acts as an airlock seal. This allows it to maintain a critical pressure difference between two areas, such as between a pressurized pneumatic conveyor system and a storage tank at normal atmospheric pressure. By doing so, it enables material to flow through without letting the valuable pressure escape, making it an indispensable component in industries ranging from plastics and food processing to pharmaceuticals and chemical manufacturing.

What Is a YJD-HG Square Unloader?

A YJD-HG Square Unloader is a specialized rotary airlock device designed with a square inlet and a hardened structural body. It is used to discharge dust, powders, flakes, and granules from hoppers, cyclones, silos, and dust collectors while preventing air leakage and maintaining system pressure balance.

The “HG” series is an upgraded version featuring enhanced sealing, reinforced end covers, and increased wear resistance, making it ideal for demanding industrial applications.

Why the YJD-HG Square Unloader Is Important

The YJD-HG Square Unloader is essential in material handling systems because it:

Maintains airtight sealing, preventing air leakage in pneumatic systems.

Ensures continuous, uniform discharge of materials.

Prevents material bridging and clogging.

Improves dust collector efficiency.

Enhances overall system stability and conveying performance.

Protects equipment from pressure fluctuations.

Without a high-quality rotary valve, industries face issues like dust backflow, inconsistent feeding, equipment wear, and energy loss.

Types and Specifications of YJD-HG-Square Unloader

Type | Inlet/Outlet Size (mm) | Capacity (m³/h) | Speed (RPM) | Motor Power (kW) | Material | Pressure Resistance (MPa) |

YJD-HG-4 | 150×150 | 2 | 24 | 0.55 | Cast Iron | 0.1 |

YJD-HG-6 | 180×180 | 5 | 22 | 0.75 | Carbon Steel | 0.1 |

YJD-HG-8 | 200×200 | 8 | 20 | 1.1 | Stainless Steel | 0.2 |

YJD-HG-10 | 220×220 | 12 | 18 | 1.5 | Cast Iron | 0.2 |

YJD-HG-12 | 250×250 | 18 | 16 | 2.2 | Carbon Steel | 0.25 |

YJD-HG-14 | 280×280 | 25 | 16 | 3.0 | Stainless Steel | 0.3 |

YJD-HG-16 | 300×300 | 35 | 14 | 3.0 | Carbon Steel | 0.3 |

YJD-HG-18 | 330×330 | 50 | 12 | 4.0 | Stainless Steel | 0.4 |

YJD-HG-20 | 360×360 | 65 | 12 | 4.0 | Cast Iron | 0.4 |

YJD-HG-22 | 400×400 | 80 | 10 | 5.5 | Stainless Steel | 0.5 |

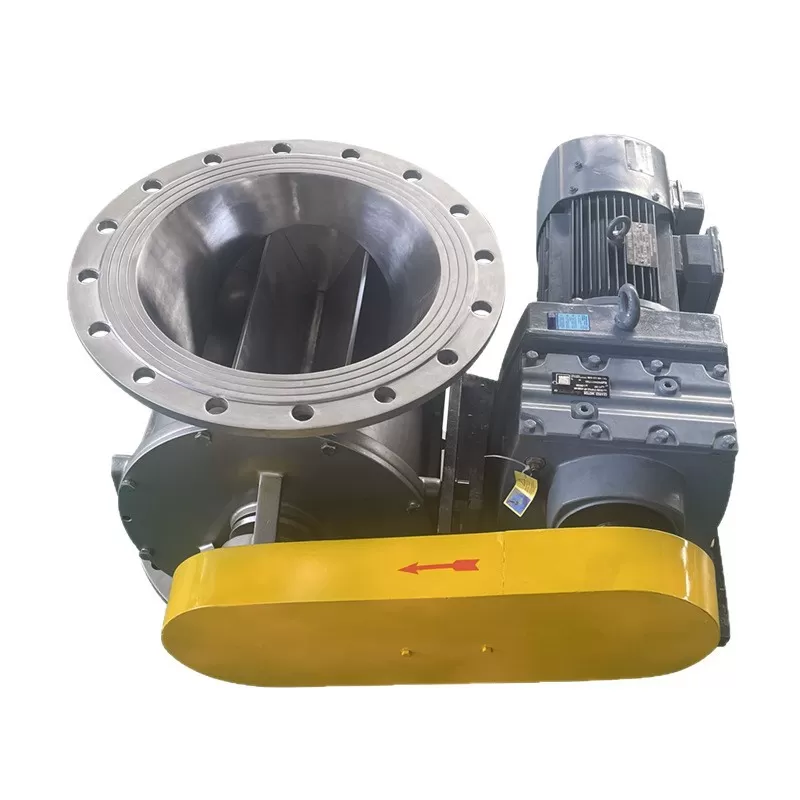

Product Description

Senotay’s YJD-HG Square Unloader is engineered with precision components and robust materials, making it suitable for continuous 24/7 industrial operations.

Key features include:

Thickened cast iron or steel housing for heavy-duty applications.

Precision-machined rotor with optimal blade clearance.

Upgraded sealing structure for airlock reliability.

High-efficiency gear motor for stable torque output.

Square mounting flange for easy installation on dust collectors and silos.

Dust-tight, pressure-resistant construction for demanding environments.

Available Types: YJD-HG-4, YJD-HG-6, YJD-HG-8, YJD-HG-10, YJD-HG-12, YJD-HG-14, YJD-HG-16, YJD-HG-18, YJD-HG-20, YJD-HG-22

YJD-HG Square Unloader — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Model Size: 200–600 mm | −0.04 to +0.12 MPa | HT250 / QT450 / SS304 | 0.75–5.5 kW | 4–12 years |

Length: 520–1,150 mm | 90 °C (Standard)

320 °C (High-Temp) | 45# Steel / SS304 | 18–42 rpm | ISO 9001 / CE |

Width: 410–820 mm | ≥ 97% | 8–14 mm | 35–70 Nm | ≤ 0.3% leakage |

Height: 360–780 mm | 7–65 m³/h | Double-Lip PTFE / Graphite | 95–520 kg | IP55 |

Square Flange Size: 200×200–600×600 mm | ≤ 340 Pa | Reinforced Cast Steel | 8–24 holes Ø14–Ø22 mm | 18–24 months |

(BCD): 170–520 mm | 1.6 t/m³ | Epoxy (120 μm) / Polyurethane (160 μm) | 900–1,500 h | ≥ 320,000 |

Inlet Opening: 190–590 mm | ≤ 15 mm | 8–16 mm | 2–4 pcs | EN 15089 |

Outlet Opening: 190–590 mm | 15–48 rpm | Heavy-Duty Roller | ≤ 63 dB(A) | C3–C4 |

How It Works – Working Mechanism

Material falls into the square inlet and fills the rotor chambers.

The rotor rotates at a constant speed using the geared motor.

Material is transported to the discharge port while maintaining complete airtight sealing.

Discharged material moves into the next processing stage without air pressure loss.

This process ensures steady flow control, protects equipment, and enhances system performance.

Core Components

A complete YJD-HG Square Unloader consists of:

Square inlet flange.

Reinforced body housing.

Precision-welded rotor.

Sealed end covers with enhanced gaskets.

High-strength transmission shaft.

Heavy-duty bearing assembly..

Gear reducer motor

Optional wear-resistant coatings.

Star feeder rotor (multi-blade design).

These components work together to provide smooth rotation, minimal friction, and reliable material discharge.

YJD-HG Square Unloader Installation Method

Position the unloader under the silo or dust collector outlet.

Align the square flange and mount using high-strength bolts.

Ensure rotor shaft alignment to avoid mechanical interference.

Connect the geared motor to the electrical supply using proper grounding.

Confirm correct rotation direction before operation.

Install flexible joints if connecting to pneumatic conveying pipelines.

Conduct a trial run to ensure quiet, smooth, vibration-free operation.

Correct installation ensures maximum efficiency and long operational life.

YJD-HG Square Unloader Material Properties

Available materials:

HT250 Cast Iron – standard use..

Q235 Carbon Steel – robust, economical.

Stainless Steel 304/316 – corrosion-resistant, ideal for food & chemical industries.

Hard-wearing alloy coatings – for abrasive dust like cement, slag, or fly ash.

High-temperature configurations for systems above 250°C.

These materials are selected based on industry demands and environmental conditions.

Why It’s Important to Invest in the YJD-HG Square Unloader

Longer lifespan due to reinforced body and advanced sealing

Stable and continuous operation

Minimal maintenance requirements

Improved energy efficiency

Higher dust collection accuracy

Reduced system downtime

Supports high-temperature and abrasive material handling

Investing in a high-quality rotary valve significantly reduces operational costs and enhances reliability.

FAQs

1. What materials can the YJD-HG Square Unloader handle?

Answers:Suitable for powders, dust, flakes, granules, and abrasive materials.

2. Can it operate at high temperatures?

Answers:Yes, customized versions operate safely up to 300°C.

3. What is the difference between HG and standard rotary valves?

Answers:The HG series features stronger sealing, reinforced structure, improved durability, and better performance.

4. Does Senotay offer customization?

Answers:Yes—materials, size, motor power, coatings, and designs can be fully customized.

5. What industries use the YJD-HG Square Unloader?

Answers:Cement, mining, food processing, chemical plants, grain mills, power plants, and any industry using dust collection or conveying systems.