The Rotary Valve: A Precision Gatekeeper for Industry

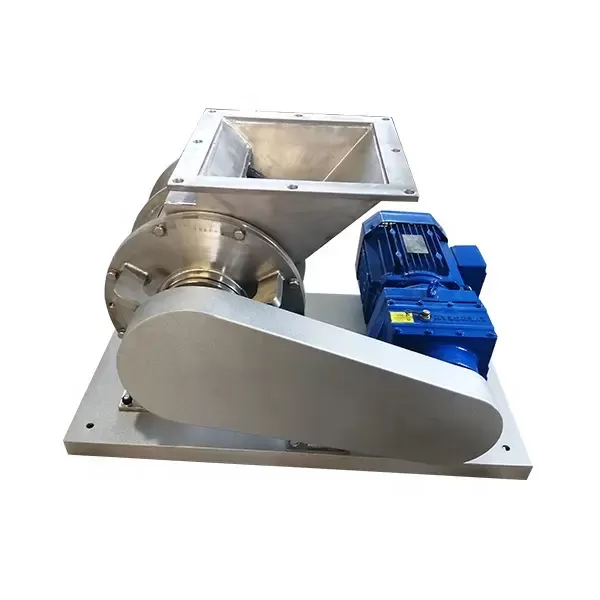

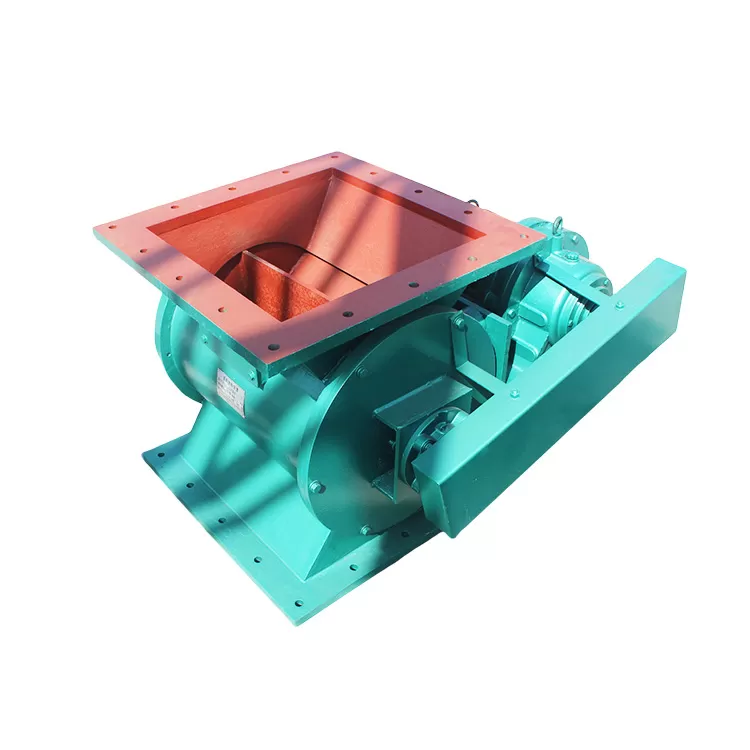

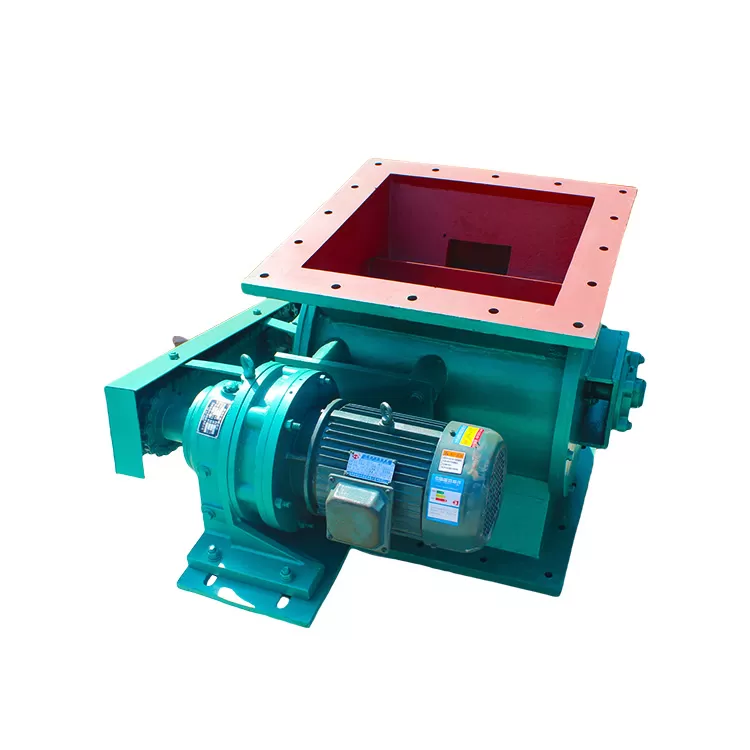

A rotary valve is a fundamental mechanical device used to control the flow of dry, bulk materials like powder, granules, or pellets. Its primary role is to function as a precision gatekeeper, consistently discharging a set amount of material from one chamber to another.

More importantly, it acts as an airlock seal. This allows it to maintain a critical pressure difference between two areas, such as between a pressurized pneumatic conveyor system and a storage tank at normal atmospheric pressure. By doing so, it enables material to flow through without letting the valuable pressure escape, making it an indispensable component in industries ranging from plastics and food processing to pharmaceuticals and chemical manufacturing.

What is YCD-HG-Square Unloader?

The YCD-HG-Square Unloader, also known as an airlock valve or rotary actuator, is a precision-engineered industrial device designed to discharge, convey, and control granular or powdered materials from dust collectors, silos, hoppers, and filters. Senotay’s YCD-HG series features a square outlet design that ensures airtight operation, preventing air leakage and material flow disruptions.

As a leading YCD-HG-Square Unloader manufacturer, Hebei OuTai Environmental Protection Equipment Co., Ltd. (Senotay) focuses on integrating durability, efficiency, and advanced material technology to serve industries such as cement, pharmaceuticals, metallurgy, food processing, and environmental engineering.

Types of YCD-HG-Square Unloader (Specifications Table)

Type No. | Inlet/Outlet Size (mm) | Capacity (m³/h) | Motor Power (kW) | Rotation Speed (RPM) | Temperature Limit (°C) | Material Options |

YCD-HG-01 | 150×150 | 2.5 | 0.37 | 15 | 200 | Cast Iron / SS304 |

YCD-HG-02 | 200×200 | 5 | 0.55 | 20 | 250 | Carbon Steel |

YCD-HG-03 | 250×250 | 8 | 0.75 | 25 | 250 | Stainless Steel |

YCD-HG-04 | 300×300 | 12 | 1.1 | 30 | 300 | SS316 |

YCD-HG-05 | 350×350 | 15 | 1.5 | 30 | 300 | Carbon Steel |

YCD-HG-06 | 400×400 | 20 | 2.2 | 35 | 350 | SS304 / SS316 |

YCD-HG-07 | 450×450 | 25 | 3.0 | 35 | 350 | Carbon Steel |

YCD-HG-08 | 500×500 | 30 | 4.0 | 40 | 400 | Alloy Steel |

YCD-HG-09 | 550×550 | 35 | 5.5 | 40 | 400 | SS316 |

YCD-HG-10 | 600×600 | 50 | 7.5 | 40 | 400 | Stainless Steel / Customized |

Product Description

The YCD-HG-Square Unloader is a rotary airlock valve with a square flange connection, designed to handle high bulk material volumes efficiently. It features:

Compact and rigid structure for stable operation.

High air-tightness performance to prevent air leakage.

Smooth rotation with a high-precision rotary actuator.

Available in multiple models with varied capacities and material options.

These unloading devices are built for continuous, heavy-duty applications, ensuring optimal dust collection and material transfer efficiency in industrial plants.

YCD-HG Square Unloader — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Model Range: 200–700 mm | Working Pressure: −0.04 to +0.10 MPa | HT250 / QT500 / SS304 | 0.75–7.5 kW | 5–12 years |

Length: 540–1,280 mm | Operating Temp: ≤ 120 °C | Carbon Steel / SS304 | 18–45 rpm | 18–24 months |

Width: 430–880 mm | Max Temp: 320 °C | PTFE / Graphite Double Seal | 40–85 Nm | ISO 9001 / CE |

Height: 380–820 mm | Airlock: ≥ 98% | Heavy-Duty Roller | 110–640 kg | ≤ 0.25% leakage |

Square Flange Size: 200×200–700×700 mm | Flow Rate: 9–75 m³/h | 8–18 mm | 8–28 holes (Ø14–Ø24 mm) | IP55 |

BCD: 170–580 mm | Pressure Drop: ≤ 360 Pa | Epoxy 120 μm

Polyurethane 160 μm | 2–4 points | C3–C4 |

Inlet Opening: 190–690 mm | Material Density: ≤ 1.8 t/m³ | Reinforced Cast Steel | ≤ 4.5 mm/s | ≥ 350,000 cycles |

Outlet Opening: 190–690 mm | Max Particle Size: ≤ 18 mm | : Machined (Ra ≤ 3.2 μm) | 1,000–1,600 h | EN 15089 |

Core Components

Housing/Body: High-strength, corrosion-resistant casting.

Rotor: Precisely machined with six to eight blades for efficient discharge.

End Covers: Precision-fit covers that ensure air-tight sealing.

Bearings: Heavy-duty bearings for high-speed rotation and minimal vibration.

Drive Motor: Optional rotary actuator or electric motor drive with variable speed.

Sealing System: Ensures zero air leakage and dust containment.

YCD-HG-Square Unloader Installation Method

Ensure a clean, level surface on the hopper or outlet.

Align the square flange of the unloader with the system outlet.

Use the provided bolt holes to secure the unit tightly.

Connect the rotary actuator or motor to the power supply following control specifications.

Test rotation speed and sealing integrity before full operation.

Pro Tip: Always install the airlock valve vertically to guarantee consistent discharge flow and avoid material backflow.

YCD-HG-Square Unloader Material Properties

Component | Material | Properties |

Housing | Cast Iron / Carbon Steel | High durability & anti-abrasion |

Rotor | Stainless Steel | Corrosion-resistant & smooth surface |

Shaft | Alloy Steel | High tensile strength |

Bearings | Heat-treated Steel | Long service life |

Seal | PTFE / Rubber | Excellent air-tightness |

How It Works

The YCD-HG-Square Unloader operates on the rotary airlock principle. As the rotor turns, each pocket receives a measured quantity of material from the inlet. When it rotates, the material is sealed off from the air pressure differential and discharged at the outlet. This ensures continuous, regulated flow of material without air loss or dust leakage.

Technical Advantages in Manufacturing YCD-HG-Square Unloader (Senotay)

At Senotay (Hebei OuTai Environmental Protection Equipment Co., Ltd.), every YCD-HG-Square Unloader is manufactured under advanced CNC machining, ensuring high manufacturing precision and smooth surface finishing.

Technical advantages include:

ISO-certified production process.

Precision balancing of rotors.

Corrosion-resistant coatings for extended life.

Advanced sealing technology for zero-leak performance.

Full inspection and testing for each product before delivery.

FAQs

Q1: What makes the YCD-HG-Square Unloader different from a round-type unloader?

Answers: The square design allows for more efficient air sealing and better material handling in high-pressure environments.

Q2: Can the YCD-HG series be customized?

Answers: Yes, we provide various sizes, materials, and actuator options depending on the operating conditions.

Q3: What maintenance does it require?

Answers: Regular lubrication of bearings and inspection of seals and rotor blades ensure longevity.

Q4: Does Senotay provide installation support?

Answers: Yes, professional installation guidance and after-sales technical support are offered worldwide.