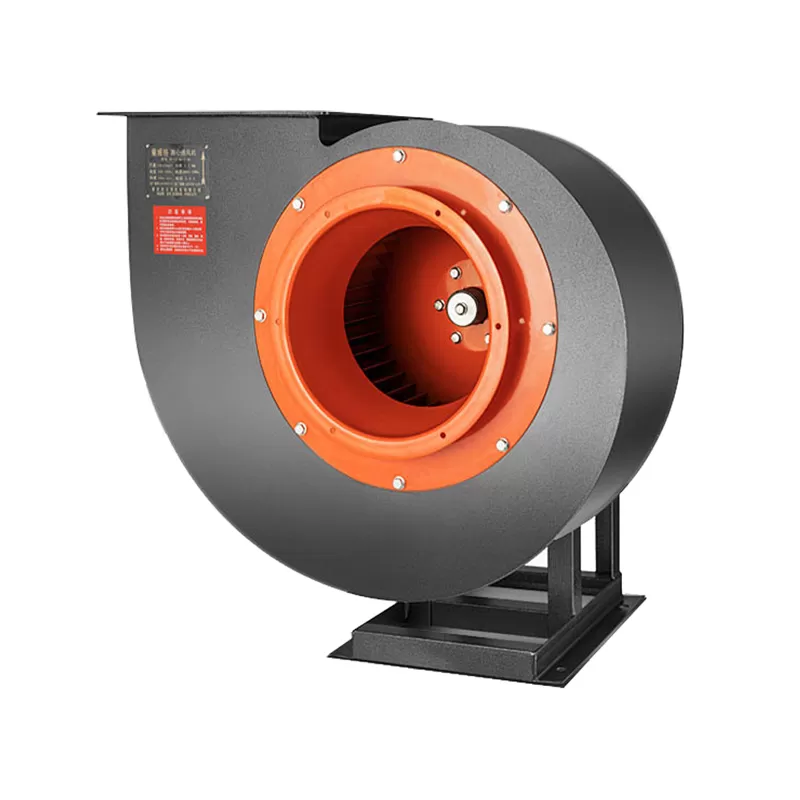

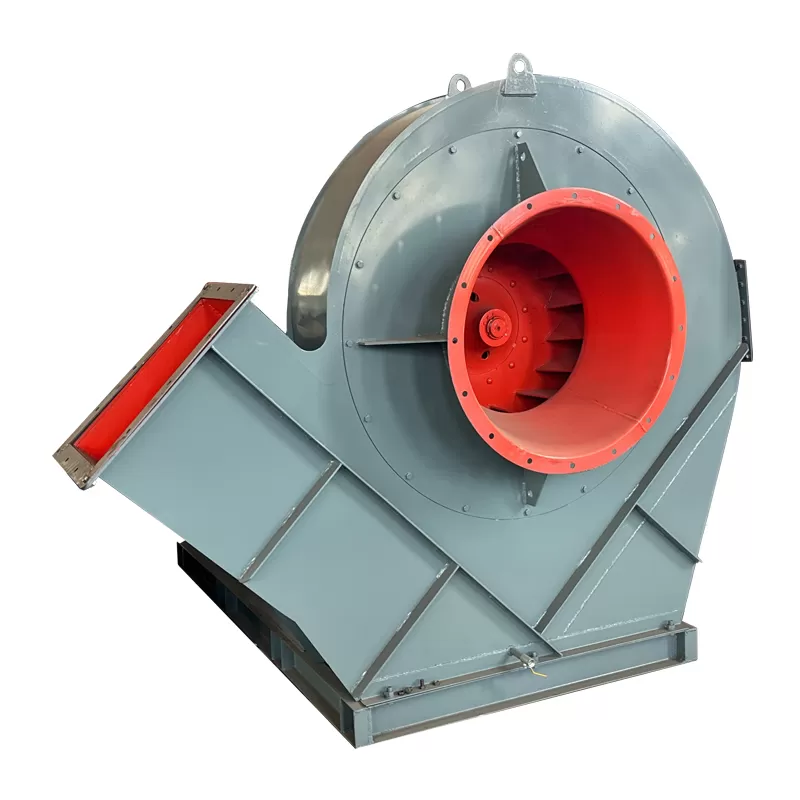

What is the Y5-47 Industrial Blower?

The Y5-47 Industrial Blower which is a high performance centrifugal induced draft fan designed specifically for industrial boiler system, furnace and heavy-duty ventilation applications.The Y5 model which is Engineered by Hebei OuTai Environmental Protection Equipment Co., Ltd. Where this powerful blower efficiently handles high-temperature gas streams including providing stable airflow and maintaining optimal furnace pressure for complete combustion.

It is specially Built to withstand extreme operational demands where the Y5-47 series offers superior air handling with energy efficiency and durability which making it an ideal solution for power generation plant, cement production, chemical processing and metallurgical operations and aslo many others.

Why Y5-47 Industrial Blower will be your perfect choice

Choosing the Y5-47 industrial boiler fan ensures a trusted, high-efficiency, low-maintenance air handling solution. Senotay’s Y5-47 centrifugal fan stands out due to:

High Efficiency that’s up to 87% : this is backward curved impeller blades optimize aerodynamic performance and energy savings.

Robust Design : Here the Y5-47 Industrial Blower is designed with heavy-duty Q235 carbon steel or 304/316 stainless steel construction for long-term durability.

Wide Performance Range : inside the system air volume from 1,323 to 48,410 m³/h and pressure from 1,049 to 2,824 Pa.

Heat Resistance : the system continuous operation at up to 250°C.

Certified Quality :This is certified by ISO 9001:2015 and CE Marking.

With flexible drive configuration with high-temperature resistance and low vibration. Y5-47 induced draft fan provides longevity and performance reliability across industries.

Y5-47 Industrial Blower Types and Specifications

Model Type | Air Volume (m³/h) | Total Pressure (Pa) | Motor Power (kW) | Efficiency (%) | Weight (kg) | Drive Type |

Y5-47-3.15C | 1,323 | 1,049 | 2.2 | 85.0 | 190 | Belt Drive |

Y5-47-4C | 2,450 | 1,150 | 4.0 | 85.8 | 265 | Belt Drive |

Y5-47-5C | 3,820 | 1,230 | 7.5 | 86.1 | 320 | Belt Drive |

Y5-47-6D | 6,550 | 1,420 | 18.5 | 87.2 | 585 | Direct Drive |

Y5-47-7D | 8,980 | 1,680 | 22.0 | 86.8 | 670 | Direct Drive |

Y5-47-8D | 11,430 | 1,950 | 30.0 | 86.0 | 750 | Direct Drive |

Y5-47-9D | 15,260 | 2,140 | 45.0 | 86.5 | 860 | Direct Drive |

Y5-47-10D | 20,810 | 2,320 | 55.0 | 86.2 | 940 | Direct Drive |

Y5-47-11D | 32,410 | 2,620 | 75.0 | 85.6 | 1100 | Direct Drive |

Y5-47-12.5D | 48,410 | 2,824 | 110.0 | 85.3 | 1350 | Direct Drive |

Y5-47 Industrial Blower – Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Length: 1650 mm | Static Pressure: 2,300–3,800 Pa | Q345 Steel | 240 Nm | 30,000–40,000 hrs |

Width: 1280 mm | Airflow Capacity: 6,500–24,000 m³/h | Carbon Steel Q235B | 8 × Ø18 mm | 36–48 months |

Height: 1420 mm | Operating Pressure: 1.5 Bar | 45# Steel | 960 kg | ISO 9001 / CE |

Inlet Diameter: Φ400 mm | Max Pressure: 1.9 Bar | Heavy-duty Self-aligning | 11–45 kW | > 15,000 cycles |

Outlet Flange: 300 × 380 mm | Operating Temp: 80–180°C | Graphite Packing | 1450–2900 rpm | > 100,000 cycles |

BCD: 450 mm | Max Temp: 250°C | 90–140 μm | ≤ 6.3 mm/s | 12–18 months |

Base Plate Thickness: 12 mm | Efficiency: ≥ 85% | GB/T 12467 Level 2 | 2 × Rated 1.5 Ton | Industrial Grade I |

Product Description, Material Properties & Standards

The Y5-47 industrial blower series represents a balance between engineering precision and environmental responsibility. Each component is manufactured from high-strength materials and tested under strict international standards.

Property | Description |

Structure Material | Heavy-gauge Q235 carbon steel or 304/316 stainless steel |

Impeller Type | Backward-curved blades, dynamically balanced to G6.3 standards |

Operating Temperature | -40°C to +350°C |

Motor Power Range | 2.2 kW to 110 kW |

Efficiency Range | ≥ 85% (up to 87.2%) |

Pressure Range | 1,049 – 2,824 Pa |

Airflow Range | 1,323 – 48,410 m³/h |

Protection Class | IP55 |

Certifications | ISO 9001:2015, CE Marking |

The Working mechanism for Y5-47 Industrial Blower

The Y5-47 centrifugal fan operates on the principle of centrifugal force to move air and exhaust gases effectively:

Gas Intake: For gas elements here inside the system Air or flue gas enters the impeller eye axially .

Energy Transfer: For transfering enegrgy the rotating impeller accelerates the gas radially that increasing its velocity and kinetic energy.

Pressure Conversion: In the preassure conversion section the volute casing converts this kinetic energy into static pressure for efficient system airflow.

System Exhaust: Pressurized gas exits through the outlet flange where its ensuring stable draft for boilers and furnaces.

This efficient mechanism ensures the Y5-47 fan maintains system pressure that enhances fuel combustion, and minimizes energy losses.

Industries that use Y5-47 Industrial Blower

The Y5-47 industrial boiler fan is used by industries where high-efficiency gas movement and durability are critical:

Power Plants :The boiler exhaust and induced draft handling.

Cement & Metallurgy Plants :For Cement & Metallurgy Plants it works in kiln and furnace fume extraction.

Chemical Processing Units : Here it handling corrosive gases and fumes.

Environmental Systems : The system prevent form air pollution control and dust collection units.

Waste Heat Recovery Systems : It able to maintaining airflow in high-temperature systems.

Key Features of the Y5-47 Industrial Blower

Expansive Model Range: From No. 3.15C to No. 12.5D.

High Aerodynamic Efficiency: Over 86.5% internal efficiency.

Long-Life Bearings: Rated for 100,000+ hours (L10 life).

Low Noise & Vibration: ≤ 2.5 mm/s, 64 dB(A).

High-Temperature Operation: Up to 250°C continuous operation.

Custom Options: High-temp bearings, wear-resistant coatings, stainless steel options.

Core Components

Impeller:

Backward-curved blades for efficiency and stability.

Wear-resistant material options for abrasive gas streams.

Casing & Frame:

Precision-rolled volute casing made of Q235 steel.

Heavy-duty frame for thermal and vibration resilience.

Drive & Bearing Assembly:

Available in C-type (belt drive) and D-type (direct drive) configurations.

Long-life pre-lubricated bearings for low maintenance.

Shaft & Sealing System:

Carbon steel shaft (45#) and advanced dust-sealing systems protect bearings and internal parts.

Installation Method for Y5-47 Industrial Blower

Base-Mounted Configuration in compliance with ISO 10816 vibration standards.

Align blower and duct/flue connections accurately to avoid system strain.

Kindly Ensure proper foundation to minimize vibration and noise.

Please Regularly inspect impeller clearance and belt tension (for C-type).

Technical Advantages in Manufacturing by Senotay

Senotay which is mainly known as Hebei OuTai Environmental Protection Equipment Co., Ltd. that integrates cutting-edge R&D, manufacturing and Its ISO-certified quality control systems to produce world-class industrial centrifugal fans.

Key technical strengths include:

In-house aerodynamic simulation testing ensuring optimal efficiency.

Dynamic balancing of impellers using CNC precision.

Stringent material traceability and safety testing with CE compliance.

Custom engineering options for unique airflow, pressure and material requirements.

FAQs — Y5-47 Industrial Blower

1. What is the difference between Y5-47 and standard centrifugal fans?

Answers:The Y5-47 model is mailny engineered for high pressure and temperature, specifically for boiler and furnace induced draft applications while standard fans serve general ventilation.

2. What is the temperature limit for the Y5-47 industrial fan?

Answers:It can handle continuous operation up to 250°C or (482°F) with optional upgrades for higher resistance.

3. Can I customize the blower for corrosive environments?

Answers:Yes it can , we Senotay offers 304/316 stainless steel and special coatings for corrosive gas handling.

4. How often should maintenance be performed?

Answers:

Daily: must needed Visual and noise checks

Weekly:Keep noticing in Lubricant and temperature monitoring

Annually: Full inspection and dynamic balancing

5. Does the Y5-47 blower meet international standards?

Answers:Absolutely yes , Each blower meets ISO 9001:2015, CE and ISO 10816 vibration and safety requirements.