What is XLED Type Cycloid Reducer?

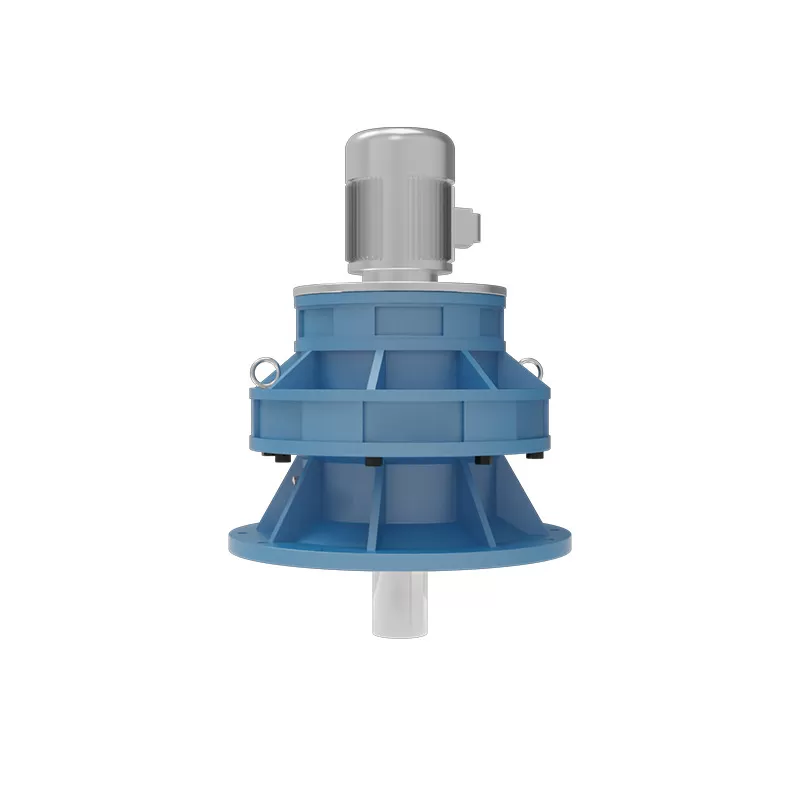

The XLED Type Cycloid Reducer is a state-of-the-art precision cycloidal drive system that offers great torque, almost no backlash, and very long life in a small size. Senotay (Hebei Outai Environmental Protection Equipment Co., Ltd.) produces this reduction gear of extreme performance which combines principles of planetary motion with cycloidal motion to provide power transmission that is smoother and more reliable than that of any conventional gearbox.

The XLED cycloid reducer features an industrial-grade construction and an ISO 9001:2015 certification, which results in 98.2% efficiency and torque capacity of 92,000 Nm. The device is small, controlled for vibrations smartly, and ready for IoT connectivity, thus making it a perfect fit for tough tasks like robotics, CNC machines, heavy conveyor belts, and smart automation systems.

What are the benefits of the XLED Type Cycloid Reducer?

Choosing the XLED cycloidal planetary reducer over others gives you major benefits that no other drive can offer:

Compact Size and High Power Density – Shrank by 30% compared to the standard, yet the XLED offers 300% more torque per volume.

Ultra-Precision Motion Control – Backlash less than 1 arcmin guarantees exceptional repeatability for the application of CNC and Robotics.

High Load Bearing – A 12-point rolling contact system opens up all the ways for an even load distribution thus having less-friction operation.

Extreme Environment Resistance – The IP69K housing can operate in temperatures from -55°C to +160°C.

Very Long Service Life – The hardened alloy gear discs (HRC 62±1) can be used continuously for over 50 thousand hours.

Eco-friendly – The cycloidal drive mechanism lessens the mechanical losses and gives a certification of >94% mechanical efficiency.

All Over the Globe Standard Compliance – Certified with CE, RoHS, AGMA 9005-E02, and DNV-SE-0078.

Product Description & Material Properties

The XLED Type Cycloid Reducer integrates robust metallurgy and precision engineering to guarantee reliability and strength even under continuous high-load conditions.

Component | Material / Process | Properties |

Housing | ADI 900-6 Austempered Ductile Iron / Optional Scalmalloy® RP-40 | High impact resistance, lightweight |

Cycloidal Disc | Pyrowear® 675 (AMS 5930) | Surface hardness HRC 62±1, enhanced fatigue strength |

Pin Ring | Vascomax® 300 Maraging Steel | Wear-resistant, anti-corrosive |

Bearings | Tapered Roller / Angular Contact | Zero axial play, high-load stability |

Lubrication System | Forced jet system (ISO VG 100 Synthetic Oil) | 3μm filtration for lifespan optimization |

Sealing | Gas-spring labyrinth, magnetic fluid, 316L caps | IP69K certified sealing |

Standard Mechanical Ratings:

Output Torque: 850–92,000 Nm.

Efficiency: 90–95%.

Backlash: ≤ 1 arcmin (Ultra-Precision).

Input Speed: Up to 6000 RPM

Temperature Range: -55°C to +160°C..

XLED Cycloidal Reducer Types & Specifications

Model Type | Reduction Ratio (i) | Rated Torque (Nm) | Efficiency (%) | Backlash (arcmin) | Max Input Speed (RPM) | Housing Material |

XLED-080 | 1:119 | 850 | 94 | ≤1.5 | 3500 | ADI 900-6 |

XLED-100 | 1:171 | 1250 | 94 | ≤1.0 | 4000 | Scalmalloy® RP-40 |

XLED-120 | 1:289 | 2000 | 95 | ≤1.0 | 4500 | ADI 900-6 |

XLED-150 | 1:391 | 3800 | 95 | ≤1.2 | 4800 | ADI 900-6 |

XLED-180 | 1:513 | 5200 | 95 | ≤1.2 | 5000 | Scalmalloy® RP-40 |

XLED-200 | 1:721 | 7500 | 95 | ≤1.0 | 5200 | ADI 900-6 |

XLED-250 | 1:1001 | 11500 | 95 | ≤0.8 | 5500 | Composite Steel Alloy |

XLED-280 | 1:1349 | 16500 | 94 | ≤1.0 | 5800 | ADI 900-6 |

XLED-300 | 1:1700 | 26000 | 93 | ≤1.5 | 6000 | Scalmalloy® RP-40 |

XLED-350 | 1:2100 | 40000 | 92 | ≤1.8 | 6000 | ADI 900-6 |

XLED Type Cycloid Reducer — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Model Size Range: XLED-3 to XLED-85 | Reduction Ratio: 6:1 – 121:1 | QT450 Ductile Cast Iron | Rated Input Speed: 1,500 rpm | Design Service Life: ≥ 30,000 h |

Overall Length: 160–1,150 mm | Rated Output Torque: 120–92,000 Nm | 40CrNiMo, HRC 58–62 | Max Input Speed: 2,000 rpm | ISO 9001:2015 |

Overall Height: 140–980 mm | Peak Torque Capacity: 2.5 × Rated | GCr15 Bearing Steel | Efficiency: 97–98.2% | CE Certification |

Overall Width: 120–760 mm | Backlash: ≤ 0.5 arc-min | 42CrMo, Induction Hardened | 300% (Short Time) | GB/T 19001 |

Output Shaft Dia.: Φ25–Φ160 mm | Transmission Accuracy: ≤ 1 arc-min | SKF / NSK / FAG | ≤ 60 dB(A) | RoHS (Optional) |

Input Flange Dia.: Φ90–Φ420 mm | Torque Density: 40–65 Nm/kg | NBR / Viton Double-Lip | Synthetic Gear Oil | MTBF: ≥ 50,000 h |

(BCD): Φ110–Φ480 mm | Speed Stability: ±0.3% | Grade 12.9 High-Strength Bolts | 0.8–12.0 L | Maintenance Interval: 8,000 h |

Mounting Interface: Foot / Flange / Shaft-Mounted | Input Power Range: 0.18–110 kW | Epoxy Powder Coating | –30 to +90°C | Max Start-Stop Cycles: ≥ 2,000,000 |

Unit Weight: 18–1,280 kg | Thermal Power Limit: Up to 45 kW (Natural Cooling) | ISO 1328 Grade 5 | Horizontal / Vertical | 18–24 months |

Working Mechanism of XLED Type Cycloid Reducer

The working mechanism of the XLED cycloid reducer is based on a cycloidal motion principle that transforms high-speed motor input into low-speed, high-torque output with extreme accuracy.

The input shaft drives an eccentric bearing, converting rotation to an oscillating motion.

This eccentric motion moves the cycloidal discs against stationary pins in a synchronized pattern.

The result is a smooth, rolling contact-based reduction, transferring power to the output shaft through an evenly distributed load path.

The preloaded tapered bearings prevent axial and radial play, ensuring quiet (<65 dB(A)) and vibration-free operation.

This mechanism leads to high torque density, smooth transmission, and ultra-low backlash, ideal for precision processes.

Industries Using the XLED Type Cycloid Reducer

The versatility and durability of the XLED planetary cycloidal reducer make it suitable for numerous industrial sectors:

Industrial Robotics & Automation.

CNC Machine Tools & Servo System.

Conveyor & Material Handling System.

Wind Turbines and Renewable Energy..

Aerospace & Defense Application.

Automotive Manufacturing.

Semiconductor and Electronics Assembly.

Pharmaceutical & Food Processing (NSF Certified).

Core Features of the XLED Cycloid Reducer

Compact, space-optimized design.

High-torque, low-speed performance.

Near-zero backlash (<1 arcmin).

Long service life (≥75,000 hours @110% load).

Active thermal regulation (PCM capsules & Peltier cooling modules).

Corrosion-resistant HVAF tungsten carbide coating.

Real-time monitoring via IoT sensor ports.

Core Components & Installation Methods

Core Components Include:

Installation Configurations:

Parallelism ≤0.01mm/100mm ensures precision alignment during installation.

Technical Advantages in Manufacturing at Senotay

At Senotay (Hebei Outai Environmental Protection Equipment Co., Ltd.), each XLED reducer is developed using smart CNC machining, automated surface finishing, and real-time testing systems to maintain global quality benchmarks.

100% load validation under 2.5× rated torque..

Balanced to ISO 1940 G1.6 grade for vibration minimization.

HVAF Tungsten Carbide surface coating for maximum corrosion protection.

Fully traceable laser-etched serialization for quality assurance.

B10 life testing & MTBF: 140,000 Hours (IEC 61709).

These advantages position Senotay as a leading XLED reducer manufacturer trusted by industries worldwide.

Frequently Asked Questions (FAQs)

Q1: What makes XLED cycloidal reducers different from traditional planetary gearboxes?

Answers: XLED reducers use a multi-lobe cycloidal motion with 12-point simultaneous contact, ensuring higher torque, lower wear, and zero backlash compared to standard planetary systems.

Q2: Can the XLED Type Cycloid Reducer operate in outdoor or corrosive environments?

Answers: Yes, the IP69K-rated sealing and HVAF tungsten carbide coating offer superior corrosion and moisture resistance, ideal for harsh and outdoor applications.

Q3: What are the maintenance requirements?

Answers: The system uses a forced circulation lubrication system with 3μm absolute filtration—no frequent maintenance required for up to 50,000+ operating hours.

Q4: Does Senotay offer customized configurations?

Answers: Yes, Senotay offers customized flange types, ratios, and sensor-integrated configurations per client specifications, with full compliance to AGMA, CE, and RoHS.

Q5: Where is this product manufactured?

Answers: All XLED planetary cycloidal reducers are designed and produced at Senotay’s advanced facility in Botou Industrial Development Zone, Hebei, China.