What Is a WLS Shaftless Screw Conveyor?

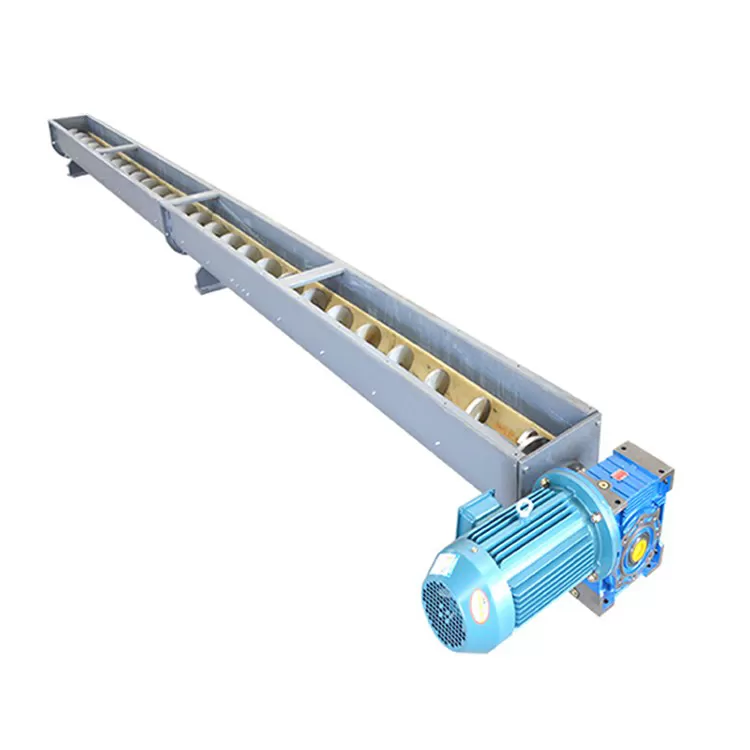

The WLS Shaftless Screw Conveyor is a high-performance conveying system engineered that is by Hebei OuTai Environmental Protection Equipment Co., Ltd-SENOTAY. Unlike conventional shaft screw conveyors, the WLS series features a shaftless spiral helix that efficiently transports sticky, viscous, or fibrous materials without the risk of clogging or jamming.

This Industrial Screw Conveyor is used across wastewater treatment plants, chemical industries, paper mills, and solid waste management facilities to move challenging bulk materials such as sludge, bio-solids and municipal waste with exceptional reliability and minimal maintenance.

Why Choose the WLS Shaftless Screw Conveyor?

Senotay’s WLS Shaftless Screw Conveyor represents an evolution in horizontal conveying technology.

It combines precision engineering, durable materials, and certified safety standards to deliver superior performance under the toughest industrial conditions.

Key Benefits:

No central shaft that means eliminates clogging and wrapping of fibrous materials.

Handles high-viscosity materials seamlessly such as sticky sludge and cellulose waste.

Heavy-duty capacity is up to 500+ m³/h and conveying lengths of 60 meters per unit.

Low maintenance cost that fewer bearings, less downtime.

Certified quality is built under ISO 9001:2015, CE, and ATEX standards.

WLS Shaftless Screw Conveyor Types and Specifications

Type No. | Model | Capacity (m³/h) | Max Length (m) | Motor Power (kW) | Material | Suitable Application |

1 | WLS150 | 15 | 20 | 1.5 | SS304 | Pilot plant & lab sludge |

2 | WLS200 | 25 | 25 | 2.2 | Carbon Steel | Food processing |

3 | WLS250 | 40 | 30 | 3.0 | SS316L | Chemical slurry |

4 | WLS300 | 65 | 35 | 5.5 | Q235 Steel | Wastewater dewatering |

5 | WLS400 | 100 | 40 | 7.5 | SS304 | Pulp & paper mill waste |

6 | WLS500 | 150 | 45 | 11 | SS316 | Municipal sludge |

7 | WLS630 | 250 | 50 | 15 | Carbon Steel (lined) | Industrial biomass |

8 | WLS700 | 350 | 55 | 22 | SS316L | Organic compost |

9 | WLS800 | 500 | 60 | 30 | Alloy Steel | Mining & aggregates |

10 | Custom | Tailor-made | 10–60 | 0.55–55 | Per Request | Custom engineering projects |

WLS Shaftless Screw Conveyor — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Conveyor Length: 1–30 m | Max Capacity: 1–35 m³/h | SS304 / SS316L / Q235 | 1.5–22 kW | ISO 9001:2015, CE |

Conveyor Width (Ø Spiral): Φ200 / Φ260 / Φ320 / Φ360 / Φ420 mm | Operating Temp: ≤ 200°C | High-strength Alloy Steel / SS304 | 20–60 rpm | 12–24 months |

Trough Height: 300–650 mm | Max Incline Angle: 0°–35° | UHMW-PE, 10–20 mm | 350–3,800 kg | 30,000–50,000 hours |

Flange Size: DN200–DN500 | Max Material Density: 0.3–1.2 t/m³ | Carbon Steel / Stainless Steel | 80–240 Nm | > 100,000 cycles |

(BCD): 240–580 mm | Throughput Efficiency: ≥ 95% | 45# Steel | ≤ 75 dB(A) | GB16297-1996 |

Section Length: 500–2,500 mm / modular | Rated Pressure: ≤ 0.1 MPa | Rubber Seal / Labyrinth Seal | 8–16 holes, Ø12–Ø20 mm | IP55/IP65 (Motor) |

Hopper Width: 300–800 mm | Start-up Load Capability: Heavy-load Start | Grade 8.8 / SS304 | –10°C to 45°C | 6–12 months |

Outlet Height: 400–1,200 mm | Energy Efficiency: ≥ 90% | Spray Paint / Polished SS | Top & Side Lug Hooks | 24/7 Continuous

|

Product Description & Material Properties

Property | Specification | Description |

Models | WLS150 – WLS800 | Wide range for diverse flow capacities. |

Capacity Range | 15 to 500+ m³/h | Adjustable per process material. |

Angle of Conveying | 0° – 30° | Suitable for horizontal or inclined layouts. |

Trough Material | Carbon Steel / Stainless Steel | Corrosion-resistant, industrial-grade construction. |

Wear Liner | UHMW-PE / Polymer | Provides excellent abrasion resistance and smooth flow. |

Drive Motor | 0.55 – 55 kW | Coupled with Cycloidal or Gear Reducer. |

How Does a WLS Shaftless Screw Conveyor Work?

Material Feed: Bulk solids, sludge, or slurry enter through a customized inlet hopper.

Spiral Motion: The shaftless spiral (screw auger) rotates inside a U-shaped trough.

Friction Reduction: The wear-resistant polymer liner reduces drag, increasing efficiency.

Material Transport: The helical motion conveys material to the discharge end.

Discharge: The outlet releases the material for further processing or collection.

Because it lacks a central shaft, the WLS Shaftless Spiral Conveyor allows material to move freely without wrapping, making it ideal for viscous, fibrous, or composite wastes that would jam traditional conveyors.

Who Uses a WLS Shaftless Screw Conveyor?

This Industrial Screw Auger Conveyor is used by industries dealing with problematic, non-homogeneous, or semi-solid materials, including:

Municipal wastewater treatment plants

Pulp & paper mills

Food processing facilities

Chemical plants

Organic waste & compost processing industries

Mining and aggregate operations

Core Features of WLS Shaftless Screw Conveyor

Shaftless spiral design for continuous operation without clogging.

U-type trough with easy maintenance and removable cover.

Replaceable wear liner for long-term protection.

High-efficiency drive assembly with cycloidal or gear reducer.

Corrosion protection for harsh environments.

Flexible installation — horizontal, inclined, or combined setups.

Core Components

Shaftless Helical Spiral: Made of wear-resistant Q235 steel or stainless steel for long durability.

U-Type Trough: 4–6 mm carbon or stainless steel with polymer liner.

Drive Assembly: High-torque cycloidal or ZJ gear reducer, 0.55–55 kW motor.

Wear-Resistant Liner: UHMW-PE or non-metallic composite reduces friction and noise.

Inlet and Outlet Ports: Multiple configuration options (square/round).

Sealing System: IP65 to IP67 protection levels for dustproof and waterproof operation.

Installation Method

Drive-end installation: Placed at discharge end to maintain spiral tension.

Trough support: Properly anchored to prevent vibration and misalignment.

Electrical integration: VFD (Variable Frequency Drive) for speed control.

Inspection ports: Allow easy access for cleaning or checking wear liners.

Technical Advantages in Senotay’s Manufacturing

Senotay integrates advanced CNC fabrication, ISO 9001 quality management, and CE/ATEX certifications in every WLS Shaftless Spiral Conveyor.

Our in-house dynamic balancing and precision welding ensure low vibration, high torque output, and long equipment lifespan (up to 70,000 hours).

Advantages at a Glance

ISO 9001:2015 & ISO 14001 certified production

CE & RoHS compliant design

Custom options: explosion-proof motors, smart monitoring, automated cleaning cycles

Low noise (<78 dB), minimal vibration (<2.2 mm/s RMS)

High energy efficiency (up to 98% under full load)

FAQs

Q1: What materials can a WLS Shaftless Screw Conveyor handle?

Answes:It can handle sludge, fibrous organic matter, viscous liquids, sticky chemicals, and solid wastes that cause blockages in traditional conveyors.

Q2: What maintenance does it require?

Answes:Minimal periodic liner inspection, lubrication of drive units, and speed calibration.

Q3: Can it be used for inclined conveying?

Answes:Yes. The horizontal screw conveyor can be installed up to a 30° incline with proper design adjustments.

Q4: What is its typical lifespan?

Answes:Ranging from 30,000 to 70,000 hours depending on model and operating conditions.

Q5: Is customization available?

Answes:Absolutely. Senotay provides custom length, diameter, motor power, and control system options.