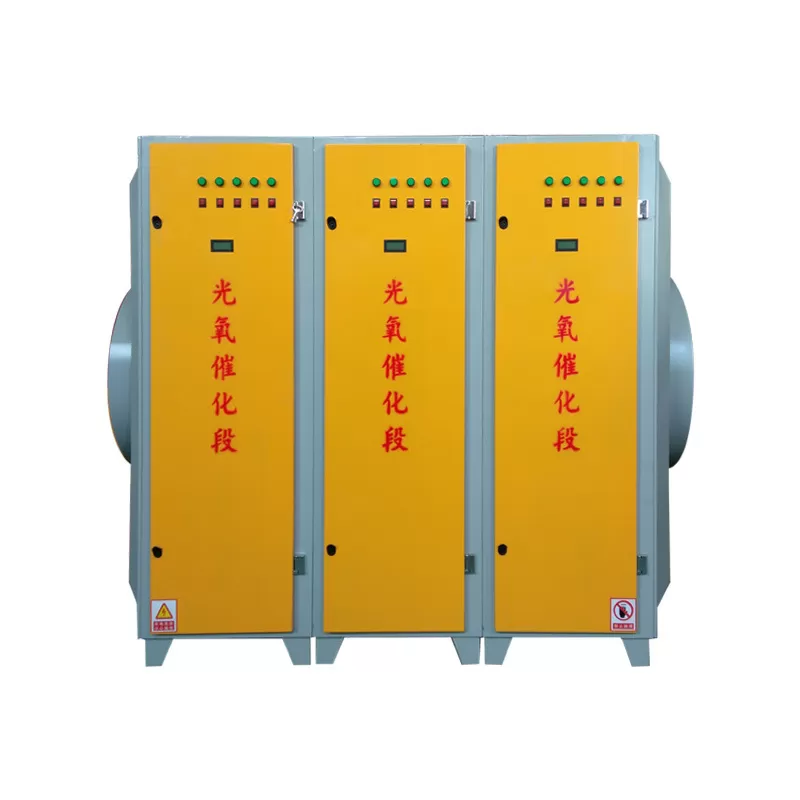

What is a UV Light Oxygen Purifier?

UV Light Oxygen Purifier is an advanced air treatment system that integrates ultraviolet C as kown as UV-C sterilization and PCO which also known as photocatalytic oxidation and activated oxygen technology for comprehensive air disinfection and purification.

This purifier is Developed by Hebei Outai Environmental Protection Equipment Co., Ltd. We are a trusted UV air purifier manufacturer . This system achieves up to 99.99% sterilization efficiency.This purifier effectively eliminating airborne microorganism, volatile organic compound, formaldehyde, benzene and unpleasant odors.

By combining UV germicidal lamps and TiO₂ photocatalysts the purifier not only kills bacteria and viruses but also decomposes harmful gases at a molecular level and converting them into harmless water and CO₂ that ensuring clean and safe and odor free air.

What Makes the UV Light Oxygen Purifier Your Best Choice?

Choosing the Senotay UV Light Oxygen Purifier ensures unmatched performance and reliability supported by over a decade of industrial air purification experience. Some reason why industries trust us:

1. Purification Efficiency–It have Superior Air Purification Efficiency Up to 99.99% .Its Advanced UV + PCO dual action ensures deep purification beyond basic filtration.

2. Certified Quality & Safety –This purifer Manufactured under ISO 9001:2015 with CE, RoHS and UL 867 compliance for trusted reliability.That is the best one.

3. Low Maintenance– This purifier made with feature that don’t need much maintainance and it can go for a long lasting life. Here its UV lamps deliver up to 18,000 hours of effective operation with minimal upkeep.

4. No Secondary Pollution –Its Chemical free disinfection guarantees an environmentally friendly purification process.

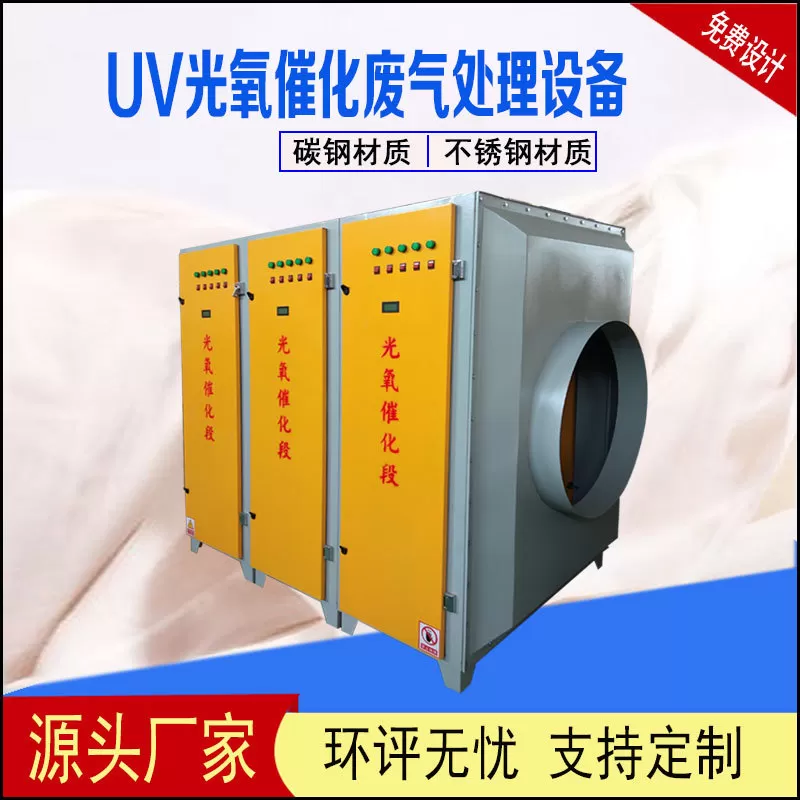

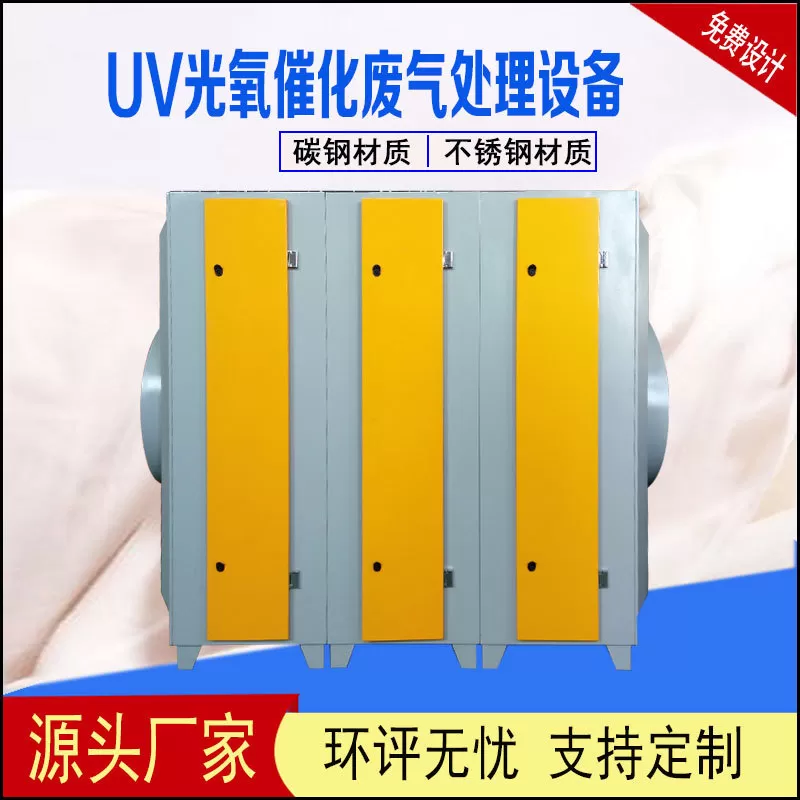

5. Compact & Modular Design – Easy to integrate into HVAC systems or install as standalone units.

Senotay’s UV Light Oxygen Purifiers are engineered for durability, efficiency and safety that’s making them the preferred choice for critical environments such as labs, hospitals and production facilities.

Product Description, Material Properties & Standards

Feature | Specification |

Model Range | UVOP Series (UVOP-500 to UVOP-12000) |

Material | 6063 Aluminum / Powder-Coated Steel – Corrosion & Heat Resistant |

Coating & Catalyst | Nano TiO₂ Photocatalyst Coating |

UV Lamp Type | Germicidal UV-C (200–280 nm) |

Lamp Life | 9,000–18,000 Hours |

Purification Efficiency | Up to 99.99% |

Power Supply | 100–240V AC, 50/60 Hz |

Compliance Standards | ISO 9001:2015, CE, UL 867, RoHS |

Airflow Capacity | 500 m³/h – 18,000 m³/h (depending on model) |

Operating Temperature | -10°C to 50°C |

The robust outer shell ensures anti-corrosion performance even under high-temperature or chemical fume environments. Every unit undergoes strict factory testing, ensuring reliable operation in demanding industrial conditions.

Types & Technical Specifications Comparison

Model | Airflow (m³/h) | Lamp Life (hrs) | Purification Efficiency (%) | Static Pressure (Pa) | Lamp Power (W) | Noise (dB) |

UVOP-500 | 500–800 | 8,500 | 95.2% | 50 | 36 | 52 |

UVOP-1000 | 1,000–1,500 | 12,000 | 96.8% | 75 | 72 | 55 |

UVOP-2000 | 2,000–3,000 | 18,500 | 97.9% | 100 | 144 | 58 |

UVOP-3000 | 3,000–4,500 | 24,000 | 98.5% | 150 | 216 | 61 |

UVOP-5000 | 5,000–7,500 | 36,000 | 99.1% | 200 | 360 | 64 |

UVOP-8000 | 8,000–12,000 | 52,000 | 99.4% | 250 | 576 | 67 |

UVOP-12000 | 12,000–18,000 | 78,000 | 99.7% | 300 | 720 | 69 |

UV-900 (In-Duct) | 3,400 | 9,000 | 99.99% | 120 | 156 | <55 |

UV-950 (Standalone) | 850 | 9,000 | 99.9% | 100 | 78 | <55 |

Custom-OEM | 500–20,000 | 10,000–18,000 | 99.9–99.99% | Custom | Custom | <65 |

UV Light Oxygen Purifier — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Length: 650–1,600 mm | Airflow Capacity: 500–15,000 m³/h | Housing Material: Q235 CS / SS304 (opt.) | Power Supply: 220 V / 380 V, 50 Hz | 10–12 years |

Width: 420–1,100 mm | Sterilization Efficiency: ≥ 99.99% | UV Lamp Type: UV-C (254 nm) | Installed Power: 0.25–3.0 kW | ISO 9001:2015 |

Height: 480–1,800 mm | Virus/Bacteria Inactivation: ≥ 99.9% | UV Lamp Quantity: 2–12 pcs | UV Intensity: ≥ 9,000 μW/cm² | CE Certified |

IFD: Φ150–Φ450 mm | VOC Removal Efficiency: 90–95% | Nano TiO₂ Coated Honeycomb | Operating Noise: ≤ 70 dB(A) | ISO 14001 |

OFD: Φ150–Φ450 mm | Formaldehyde Removal: ≥ 92% | Reflective Liner: Anodized Aluminum | –10 to 60°C | GB/T 18801 |

BCD: Φ180–Φ520 mm | Odor Removal Efficiency: ≥ 95% | Seal Material: Silicone / EPDM | ≤ 90% RH | EPA Indoor Air Std. |

Mounting Base Size: 450×400–1,400×1,000 mm | Oxygen Ion Output: 1–5 ×10⁶ ions/cm³ | Lamp Sleeve: Quartz Glass | 45–620 kg | 8,000–12,000 hrs |

Access Door Size: 300×300–500×500 mm | Pressure Drop: ≤ 600 Pa | Fasteners: SS / Grade 8.8 Bolts | 6–12 months | ≥ 24,000 hrs |

Working Mechanism

The working principle is based on UV photocatalytic oxidation technology:

UV-C Lamp Activation: Ultraviolet rays (200–280 nm) activate the TiO₂ photocatalyst surface.

Formation of Hydroxyl Radicals (•OH): Reactive radicals oxidize organic pollutants (VOCs, odors, and harmful gasses).

Decomposition Reaction: Pollutants decompose into harmless CO₂ and H₂O molecules.

Air Circulation: Clean air passes through the outlet, ensuring continuous purification.

This integrated process provides continuous sterilization and deodorization without creating ozone beyond safe limits (<0.01 ppm).

Industries That Use the UV Light Oxygen Purifier

The Senotay UV Light Air Purifier serves a wide range of industrial and commercial applications, including:

1. Pharmaceutical & Biotech Facilities.

2. Laboratories & Clean Rooms.

3. Food & Beverage Processing Plants.

4. Sewage Treatment & Odor Control Systems.

5. Painting & Printing Workshops.

6. HVAC Systems in Commercial Buildings.

7. Hospital Operating Rooms & Clinics.

8. Commercial Kitchens & Smoke Treatment Systems.

Our systems have successfully improved air safety and quality in numerous industrial air handling and purification projects worldwide.

Core Components of the UV Light Oxygen Purifier

UV-C Lamp Module – Generates germicidal UV rays to destroy microorganisms.

TiO₂ Photocatalytic Layer – Produces hydroxyl radicals to oxidize VOCs.

Activated Oxygen Unit (optional) – Enhances odor and chemical breakdown.

Air Inlet & Outlet Duct System – Ensures smooth air circulation for uniform sterilization.

Filter Device – Removes large particles and dust for pre-filtration.

Control Electronics – IoT-ready smart display and automation controls.

Housing Enclosure – High-strength, corrosion-resistant aluminum or steel.

Installation Method

Duct Mounted – Installed in air-conditioning ducts or ventilation systems for whole-building air treatment.

Standalone Type – Freestanding installation for individual rooms or zones.

Ceiling / Wall Mounted – Ideal for commercial offices, hospitals, or labs.

OEM Integration – Customizable modules for system manufacturers.

Installation typically takes 1–3 hours, with professional guidelines provided by Senotay’s technical support team.

Technical Advantages in Senotay’s Manufacturing Process

At Hebei Outai Environmental Protection Equipment Co., Ltd. Our every UV air purifier goes throug precision manufacturing and multi point quality inspection.

Key Advantages:

1. ISO 9001 Quality System Certification.

2. UL & CE Compliant UV Technology.

3. High Precision Photocatalyst Coating Equipment.

4. Long Lifetime UV Lamp Testing Systems.

5. Professional Engineering R&D Team.

6. In House Airflow & VOC Simulation Testing Labs.

Through continuous R&D, Senotay ensures every UV Light Oxygen Purifier delivers maximum performance, durability, and energy efficiency.

Frequently Asked Questions (FAQs)

Q1. Does the UV Light Oxygen Purifier produce ozone?

Answers: No, it operates safely below 0.01 ppm ozone concentration, meeting international safety standards.

Q2. How often should the UV lamps be replaced?

Answers: After approximately 9,000–18,000 hours of operation or every 12–18 months for optimal efficiency.

Q3. Can it be installed in existing HVAC systems?

Answers: Yes. The modular design allows seamless integration with new or existing HVAC systems.

Q4. What maintenance is required?

Answers: Only periodic lamp replacement and surface cleaning of the photocatalyst module.

Q5. Is this purifier suitable for food or pharmaceutical industries?

Answers: Absolutely yes. It’s specially designed for GMP-compliant clean air environments like food processing or biopharma labs.