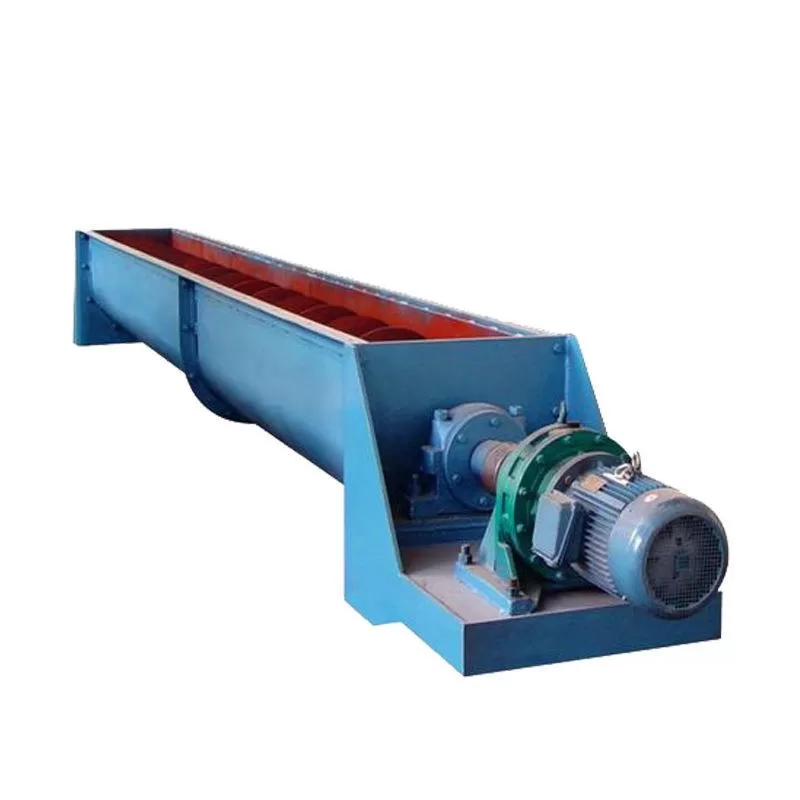

What is U-Type Screw Conveyor?

U-type screw conveyor is also called U-trough screw conveyor. Where the conveyor is an advanced industrial conveying system is specially designed for moving bulk materials efficiently within a U-shaped trough using a spiral blade like screw or auger. This machine is widely use in industries such as cement, food processing, mining, chemicals, agriculture and wastewater treatment also manymore industry.

As a CE & ISO-certified U-type screw conveyor manufacturer we Hebei OuTai Environmental Protection Equipment Co., Ltd. From china delivers durable and high-performance U-type conveyors engineered for heavy duty applications and long term operational reliability.

Purpose of choosing U-Type Screw Conveyor

Choosing a U-type screw conveyor ensures durability including dust-proof operation and simplicity in maintenance. Its U-shaped trough allows for easy inspection then quick cleaning and superior material flow control.

Here’s why industries rely on it:

Versatility: The whole system is Ideal for granules, powders, semi-moist or sticky materials.

Space efficiency: Here the empty space is Optimized for compact layouts.

Ease of maintenance: Hare the Removable covers provide quick access.

High performance: It able to handle materials up to 200°C and capacities from 5–500 m³/h.

Reliability: Proven through Senotay’s ISO 9001:2015 quality system.

U-Type Screw Conveyor Model Comparison Table

Model | Capacity (m³/h) | Screw Diameter (mm) | Power (kW) | Max Lift Height (m) | Weight (kg/m) | Noise Level |

ST-U-SC-V200 | 10–25 | 200 | 4–7.5 | 15 | 85 | ≤70 dB(A) |

ST-U-SC-V300 | 25–60 | 300 | 7.5–18.5 | 20 | 150 | ≤72 dB(A) |

ST-U-SC-V400 | 60–120 | 400 | 18.5–45 | 25 | 250 | ≤75 dB(A) |

ST-U-SC-V500 | 120–250 | 500 | 45–75 | 30 | 400 | ≤78 dB(A) |

ST-U-SC-V600 | 200–350 | 600 | 55–90 | 35 | 480 | ≤80 dB(A) |

ST-U-SC-V700 | 300–450 | 700 | 75–110 | 40 | 600 | ≤82 dB(A) |

ST-U-SC-V800 | 400–600 | 800 | 90–132 | 45 | 750 | ≤82 dB(A) |

ST-U-SC-V900 | 550–700 | 900 | 110–160 | 50 | 890 | ≤83 dB(A) |

ST-U-SC-V1000 | 600–800 | 1000 | 132–185 | 55 | 1000 | ≤85 dB(A) |

ST-U-SC-V1250 | 800–1000 | 1250 | 160–220 | 70 | 1250 | ≤86 dB(A) |

U-Type Screw Conveyor — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Conveyor Length: 1–40 m | Flow Rate: 2–120 m³/h | Q235 / SS304 / SS316L | 1.1–30 kW | ISO 9001:2015, CE |

Trough Width: 300–1,000 mm | Max Pressure: ≤ 0.12 MPa | Carbon Steel / SS304 | 20–90 rpm | 12–24 months |

Trough Height: 200–700 mm | Operating Temp: –10°C to 180°C | Bolted / Hinged | 350–4,800 kg | 25,000–45,000 hours |

Inlet Size: 250–600 mm | Max Temp (Peak): 200°C | Rubber / PTFE / Labyrinth | 80–200 Nm | 6–12 months |

Outlet Size: 200–500 mm | Conveying Efficiency: ≥ 95% | Hanging / End Bearing | 8–16 holes, Ø12–Ø20 mm | GB16297-1996 |

Flange Size: DN200–DN600 | Max Incline Angle: 0–30° | 8.8 / SS304 | ≤ 1.8 mm/s | ≥ 100,000 cycles |

Bolt Circle Diameter (BCD): 240–620 mm | Noise Level: ≤ 75 dB(A) | Painted / Powder-Coated / Polished SS | –15°C to 45°C | Continuous 24/7 |

Section Length (Modular): 1,000–2,500 mm | Power Efficiency: ≥ 88% | 3–8 mm | 2–6 welding lugs | IP55 / IP65

|

Product Description & Material Properties

Senotay’s Industrial U-Type Screw Conveyor is engineered with precision to meet demanding handling needs.

Material Properties & Construction:

Trough Material: It contain Carbon steel Q235B category or stainless steel.

Screw Flight Material: For screw we use Hardox 400 or Manganese steel ( which is 16Mn) for abrasion resistance.

Shaft Material: For shaft we use alloy steel for better strength and fatigue resistance.

Operating Temperature: -20°C to +80°C (custom designs up to 200°C).

Noise Level: ≤70–78 dB(A) ensuring quiet operation.

Protection Class: IP65 for dustproof and moisture resistance.

Standard Physical & Mechanical Properties

Parameters | Specification Range | Material Options | Capacity | Power | Temperature |

Trough Width | 150–1250 mm | Q235B / SS304 | 5–500 m³/h | 1.5–75 kW | ≤200°C |

Screw Diameter | 200–500 mm | Hardox / 16Mn | 10–250 m³/h | 4–75 kW | ≤200°C |

Shaft Material | 40Cr Alloy | - | - | - | - |

A ideal U-Type Screw Conveyor Working mechanism

The U-type screw conveyor working principle is simple yet effective. Material enters the inlet and is moved forward by the rotating helical screw. The rotational force combined with material friction pushes the bulk steadily toward the discharge outlet.

Feeding: In feeding process The huge quantity of Bulk material enters through the inlet.

Transporting: For transpering things The screw shaft rotates and moving material forward.

Discharging: Her in discharging process Material exits smoothly through the outlet and ready for the next process.

Optional Incline: It Can move materials slightly uphill based on installation angle.

This mechanism ensures continuous, clog-free and dust-controlled material transfer.

Key Features of Senotay’s

U-Shaped Trough: 3–8mm thick, carbon steel or stainless steel design.

Flanged Connections: Precision sealing to minimize leakage.

Removable Covers: Simplified cleaning and inspection.

Custom Inlet/Outlet Options: For flexible plant integration.

Optimized Flight Design: Full, reduced, or variable pitch for efficiency.

Low Maintenance: Durable bearings minimize downtime.

Quiet Operation: Multi-point isolation reduces vibration and noise.

Core Components

U-Shaped Trough System – Dust-sealed and corrosion-resistant.

Screw Assembly & Flighting – Heavy-duty helix built for efficiency.

Bearings (M1/M2) – Optional rolling or sliding bearings for temperature-specific use.

Drive Motor & Gear Reducer – Optimized power-to-torque ratio ensures mechanical reliability.

Inlet/Outlet Ports – Designed for smooth and precise material flow.

Installation Method

Installation of a U-type screw conveyor follows a systematic approach:

Securely mount the trough sections on flat, aligned supports.

Join sections using flanges and gaskets for dust-tight sealing.

Install the screw shaft with proper bearing alignment.

Connect the drive motor via coupling or gear reducer.

Perform a test run to ensure silent and vibration-free operation.

Technical Advantages of Senotay Manufacturing

At Hebei OuTai Environmental Protection Equipment Co., Ltd. (Senotay), every U-type screw conveyor is produced under strict ISO and CE standards with precision fabrication.

Advantages Include:

CNC machining for accuracy.

Heat treatment for longer shaft life.

Wear-resistant coating on screw flights.

Custom capacity design (5–500 m³/h).

Pre-assembly testing ensures performance consistency.

FAQs – U-Type Screw Conveyor

Q1. What materials can be conveyed using a U-type screw conveyor?

Answers: Powders, grains, cement, sludge, and semi-liquid materials.

Q2. What are the temperature limits?

Answers: Standard design handles up to 200°C; custom options are available for higher ranges.

Q3. Can U-type screw conveyors be used for inclined applications?

Answers: Yes, for moderate inclines (up to 20°) with proper design.

Q4. What certifications does Senotay hold?

Answers: Certified by ISO 9001:2015 and CE for global reliability and safety standards.

Q5. Can the conveyor be customized?

Answers: Yes, Senotay offers design customization for size, material, and configuration.