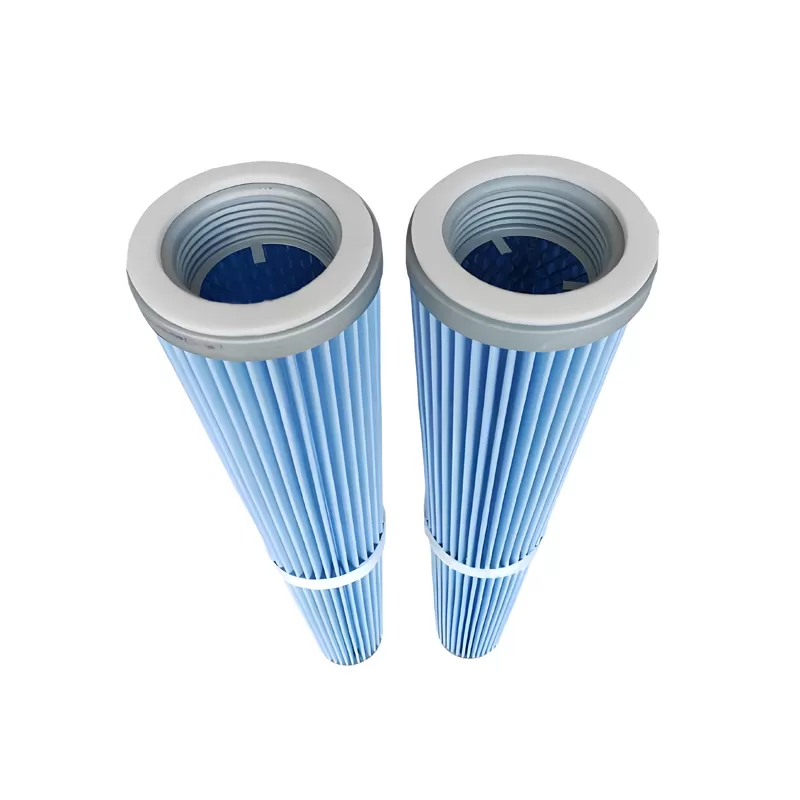

What is a Threaded Dust Filter Element?

A Threaded Dust Filter Element is a precision-engineered filter cartridge which is designed with threaded end caps for secure installation and airtight sealing in industrial dust collection systems. These filters ensure efficient separation of fine dust, fumes and particulate matter from process air, maintaining clean air quality and operational efficiency.

Threaded designs allow for quick installation and replacement without the need for additional clamps or gaskets, making them ideal for compact or high-vibration dust collectors in heavy-duty industrial environments.

Why Threaded Dust Filter Elements Are Important for Dust Collection Systems

A dust collection system is only as effective as its filter element. The threaded dust filter element provides a reliable seal and robust filtration performance, ensuring:

· Consistent airflow and low pressure drop

· Enhanced filtration efficiency for fine particles

· Reduced downtime due to easy filter replacement

· Longer equipment lifespan through contamination control

· Compliance with air quality regulations in industrial facilities

By maintaining clean, filtered air, these filter elements protect both equipment and employees, ensuring safer and more productive operations.

Types of Threaded Dust Filter Elements

Type No. | Thread Size | Filter Media | Efficiency | Length (mm) | Outer Diameter (mm) | Temperature Resistance | Application |

TDFE-101 | M20 | Polyester | 99.9% | 250 | 90 | 100°C | General dust removal |

TDFE-102 | M24 | Cellulose | 98.5% | 300 | 100 | 90°C | Woodworking |

TDFE-103 | M27 | PTFE-coated | 99.99% | 320 | 110 | 150°C | Chemical |

TDFE-104 | M30 | Polyester + NanoFiber | 99.95% | 350 | 115 | 120°C | Cement |

TDFE-105 | M32 | Polypropylene | 98% | 400 | 120 | 80°C | Food processing |

TDFE-106 | M36 | Antistatic Polyester | 99.9% | 380 | 115 | 110°C | Metal processing |

TDFE-107 | M40 | PTFE membrane | 99.99% | 460 | 130 | 180°C | High-temp industries |

TDFE-108 | M42 | Synthetic fiber | 99.5% | 500 | 140 | 100°C | Foundries |

TDFE-109 | M45 | Stainless mesh + Fiber | 99.9% | 450 | 135 | 160°C | Pharmaceutical |

TDFE-110 | M48 | Polyester Felt | 99% | 480 | 125 | 120°C | Paint booths |

Why Dust Filters Are Necessary for Air Pollution Control

Airborne particulate emissions significantly affect worker health and environmental quality. Installing high-performance industrial dust collector filters mitigates dust dispersion, reduces exposure to harmful particles, and supports sustainable operations. These filters prevent environmental contamination and help industries meet strict international emission standards.

Material Properties of the Threaded Dust Filter Element

HEBEIOUTAI threaded elements are engineered from high-quality materials that offer:

Temperature resistance: up to 120°C or more.

Chemical stability: resistant to corrosive gases and moisture.

Mechanical strength: maintains structural integrity under heavy pressure.

Anti-static and oil-resistant properties for safe use in combustible dust environments.

Threaded Dust Filter Element - Model TDF-M12x1.5

Specification | Metric Value | Performance Rating | Material Grade | Certification |

Thread Specification | M12x1.5 | IP68 Sealing | 304 Stainless Steel | ISO 228-1 |

Element Dimensions | 45x85 mm | 0.8 L Volume | PPS Composite | ISO 9001 |

Filtration Rating | 5 Micron | 99.2% Efficiency | PTFE Membrane | ISO 16890 |

Max Pressure | 16 Bar | 25 Bar Burst | Glass-Filled Nylon | ISO 2941 |

Flow Capacity | 25 L/min | ΔP 0.8 Bar | - | ISO 1217 |

Temp Range | -40°C to 120°C | 150°C Peak | High-Temp Seal | UL 94V-0 |

Torque Specification | 18 Nm | ±2 Nm | Steel Insert | ISO 6789 |

Weight | 0.12 kg | ±0.01 kg | Polymer Composite | - |

Service Life | 4,000 Hours | ±200 Hours | - | Internal Test |

Vibration Resistance | 15 G | 20-2000 Hz | Locking Collar | ISO 19438 |

Standard Physical & Mechanical Properties

Property | Unit | Typical Value | Remarks |

Filtration Efficiency | % | ≥ 99.9 | Fine particulate filtration |

Air Permeability | m³/m²·min | 120–200 | Ensures efficient airflow |

Burst Strength | kPa | ≥ 250 | High mechanical durability |

Temperature Resistance | °C | 100–120 | Customized up to 200°C |

Humidity Resistance | % | ≤ 80 | Stable under moist conditions |

Anti-Static Resistance | MΩ | ≤ 10 | Safe for explosive environments |

Core Components

Filter Media Layer – Core element for dust capture

End Caps – Provide airtight sealing and structural stability

Center Core (Perforated Tube) – Ensures internal airflow support

Threaded Base – Enables firm attachment to dust collection housings

Gaskets/O-Rings – Prevent air and dust leakage

Working Mechanism

The Threaded Dust Filter Element works by drawing contaminated air through the filter media. Dust particles are trapped on the surface or within the depth of the filter layer, while clean air passes through and exits the system. Periodic cleaning (via reverse air or pulse jet) removes accumulated dust, restoring performance and extending filter life.

Main Features

Easy threaded installation and replacement

High dust holding capacity for long service life

Stable filtration efficiency even under high pressure

Corrosion-resistant and anti-static construction

Customizable sizes and filter media types

Compatible with multiple dust collection systems

Environmentally friendly and durable design

Why HEBEIOUTAI Filter Element Is the Best Choice

As a leading threaded dust filter element manufacturer in China, HEBEIOUTAI ENVIRONMENTAL PROTECTION EQUIPMENT CO., LTD. combines advanced technology with stringent quality control. Every product is tested to ensure maximum efficiency, durability, and safety, meeting both domestic and international standards.

Our advantages:

100% factory inspection before delivery.

Custom OEM & ODM services available.

Comprehensive after-sales support.

ISO & CE certified production lines.

Decades of expertise in air pollution control solutions.

Manufacturing Process of Threaded Dust Filter Element

Media Preparation: Selection and cutting of high-grade filter media.

Pleating Process: Forming pleats to increase filtration area.

End Cap Molding: Applying sealed metal or polymer end caps.

Thread Formation: CNC threading ensures precision fit.

Bonding & Assembly: High-temperature bonding ensures integrity.

Quality Inspection: Tests for airflow, efficiency, and strength.

Packaging: Vacuum and anti-static packing ensures safe transport.

Frequently Asked Questions (FAQs)

Q1: What industries use threaded dust filter elements?

A1: Industries like cement, steel, food processing, chemical, woodworking, and pharmaceuticals use them extensively.

Q2: Can I customize the size or media type?

A2: Yes, HEBEIOUTAI provides customized threaded filters to fit your dust collector specifications.

Q3: How often should the filter element be replaced?

A3: Typically after 8–12 months, depending on working conditions and dust concentration.

Q4: What is the difference between a threaded and a non-threaded filter element?

A4: The threaded type offers easier and more secure installation, reducing leakage risk compared to standard models.

Q5: Does HEBEIOUTAI offer OEM services?

A5: Absolutely. We provide OEM and ODM services, ensuring product compatibility with your brand requirements.