What is a TH Bucket Elevator?

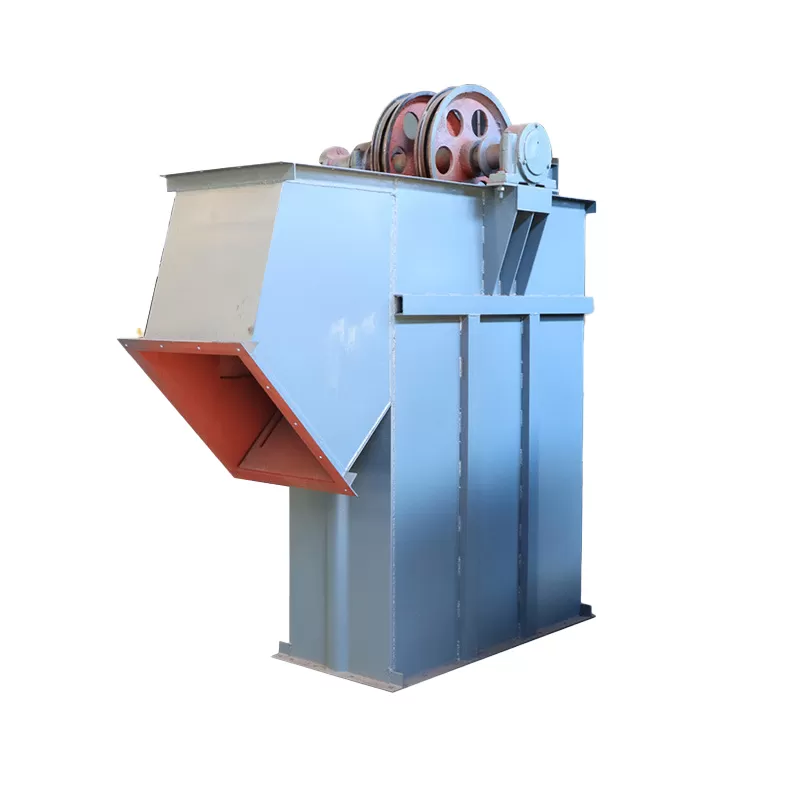

The TH Bucket Elevator where that is a high-performance vertical conveying system designed to lift bulk materials efficiently, safely and continuously. As a chain driven bucket elevator the TH model utilizes forged ring chains instead of traditional belt drives that specially offering higher tensile strength, durability for lifetime use and wear resistance.

It complies with the JB3926-85 “Vertical Bucket Elevator” industry standard and meets ISO 9001:2015 and CE certification requirements also including ensuring global quality and safety compliance. The bucket elevator have lifting heights ranging from 4.5 m to 40 m this elevator is ideal for various sectors like cement plants, mining, fertilizer processing and power generation.

What makes a buyer to choose TH Bucket Elevator?

When handling tiny abrasive, powdery or granular materials such as cement, sand, coal and fertilizer with reliability and operational safety are essential. The TH series chain bucket elevator stands out due to:

Ring Chain Drive System: Here The ring chain is built from forged alloy steel (HRC 58–62 model) .only that thing offering a lifespan of up to 10 years.

Heavy-Duty Performance: It really able to manages bulk materials with densities less than 1.5t/m³ and temperatures up to 250°C.

Customizable Design: Its customize desing according to clients for modular sections (2m each) allow flexible height adjustments.

Low Maintenance: Its Fewer wear components and robust steel casing reduce maintenance frequency.

Certified Quality: If talk about certification the product is CE-marked and manufactured under ISO 9001:2015 standards.

With a focus on longevity, safety and reliable performance TH bucket elevators are a preferred choice among industrial operators seeking stable vertical conveying solutions.

TH Bucket Elevator Types & Technical Specifications

Model | Capacity (m³/h) | Bucket Volume (L) | Speed (m/s) | Max Feed Size (mm) | Temperature Range (°C) | Chain Diameter (mm) |

TH160 | 15 | 1.2 | 1.2 | ≤20 | Up to 250 | φ16 |

TH200 | 25 | 1.9 | 1.4 | ≤25 | Up to 250 | φ16 |

TH250 | 31 | 3.0 | 1.5 | ≤30 | Up to 250 | φ18 |

TH315 | 35 | 3.75 | 1.5 | ≤35 | Up to 250 | φ18 |

TH400 | 60 | 5.9 | 1.5 | ≤40 | Up to 250 | φ18 |

TH500 | 75 | 9.3 | 1.5 | ≤50 | Up to 250 | φ22 |

TH630 | 114–185 | 14.6–23.6 | 1.5 | ≤60 | Up to 250 | φ22 |

TH800 | 200 | 30 | 1.5 | ≤65 | Up to 250 | φ25 |

TH1000 | 250 | 45 | 1.5 | ≤70 | Up to 250 | φ25 |

TH1250 | 300 | 60 | 1.5 | ≤75 | Up to 250 | φ28 |

TH Bucket Elevator – Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Lifting Height: 4,500–40,000 mm | Operating Pressure: 0.4–0.6 Bar | Forged Ring Chain (TH) | 5.5–75 kW | 10–15 years |

Bucket Width: 160–500 mm | Max Pressure: 1.0 Bar | 20Mn2 / 45Mn / 20CrMnTi | 1.0–1.5 m/s | 20,000–35,000 hrs |

Boot Section Width: 350–1,050 mm | Operating Temp: –20 to 120 °C | Q235 / Q345 Steel / Nylon | 20–400 m³/h | ISO 9001:2015 / CE |

Head Section Width: 380–1,100 mm | Max Temp: 150 °C | Q235 / Q345 Steel | ≤ 85 dB(A) | JB3926-85 |

Flange Size: Ø250–Ø780 mm | Max Material Size: ≤ 50 mm | NM360 / NM400 | 0.5–1.2 m/s | 800–1,200 hrs |

(BCD): Ø210–Ø720 mm | Filling Factor: 0.70–0.75 | 40Cr Forged Steel | Gravity / Screw | 5,000–7,500 cycles |

Footprint Length: 900–2,600 mm | Conveying Efficiency: > 90% | Rubber / Labyrinth | 1,100–8,200 kg | EN 81-31

|

Product Descriptions, Material Properties & Standard Specifications

The TH chain bucket elevator is composed of a motor-reducer assembly, casing panels, forged alloy chain, steel/HDPE buckets, and a precision tensioning system.

Material & Build Quality:

Component | Material | Properties | Standard Compliance |

Chain | Forged alloy steel | High hardness (HRC 58–62), wear-resistant | ISO 6336 |

Buckets | Carbon steel / HDPE | Abrasion & impact-resistant | ISO 2177 |

Casing | 3–5 mm thick steel | Anti-deformation & corrosion-resistant | ASTM A36 |

Drive Assembly | QT450 housing | Long service life & low noise | ISO 13752 |

Sealing | Triple-lip + labyrinth | Dustproof (IP54–IP65) | IEC 60529 |

These structural and mechanical properties ensure the TH series bucket elevator performs reliably even under harsh industrial conditions.

TH Bucket Elevator Work process

The working principle of a TH vertical bucket elevator involves a continuous loop of buckets attached to a ring chain that moves between a head sprocket and a boot sprocket.

Operation Process:

Feeding: Firstly the material enters via the inlet at the boot section.

Scooping: In scooping process buckets scoop materials through the rotating chain system.

Lifting: The chain driven buckets move vertically at controlled speed.

Discharging: In discharge part Material is released using gravity or mixed discharge.

Return Path: While returning the empty buckets move downward to scoop up fresh material.

This mechanism ensures smooth vertical conveying, minimal spillage, and continuous operation for high-demand applications.

Who Uses the TH Bucket Elevator?

TH series bucket elevators are widely used across multiple industries with including:

Cement Plants – for clinker, raw meal, and limestone handling.

Mining Operations – for ore, gravel, and coal transportation.

Power Plants – for fly ash, slag, and fuel feed systems.

Fertilizer and Chemical Plants – for granular and powder media.

Food Processing Units – for grain and feed transfer.

Their suitability for abrasive, high-temperature materials makes them a reliable choice for heavy-duty vertical conveying.

Features of TH Bucket Elevator

1. High Strength Chain: Forged alloy with fatigue resistance.

2. Large Conveying Capacity: Up to 185 m³/h depending on model.

3. Low Power Consumption: Efficient energy transfer.

4. Sealed and Dustproof Design: Complies with IP54–IP65 protection standards.

5. Flexible Unloading: Mixed or gravity discharge for process adaptability.

6. Temperature Tolerance: Operates safely up to 250°C.

7. Stable Operation: Precision engineering minimizes vibration and noise (<75 dB).

Core Components

Component | Function | Technical Standard |

Motor & Reducer | Transfers motion with controlled torque | ISO 13752 |

Sprockets | Ensures synchronized chain movement | JB3926-85 |

Forged Ring Chain | Acts as traction drive | ISO 6336 |

Buckets | Scoops and carries material | ISO 2177 |

Tensioning Device | Maintains proper chain tension | ±5% tolerance |

Casing & Frame | Provides structural stability | ASTM A36 |

Installation Method

Base Mounting: Secure the boot section horizontally.

Erection: Assemble modular casings vertically using flange joints.

Chain Installation: Attach chain and buckets sequentially.

Alignment: Ensure sprockets and shafts are perfectly aligned.

Testing: Run dry operations for 30–60 minutes before full loading.

Professional installation ensures efficiency and extends service life.

Technical Advantages in Manufacturing (Senotay)

As a leading TH bucket elevator manufacturer, Hebei OuTai Environmental Protection Equipment Co., Ltd. (Senotay) integrates advanced mechanical design and precision manufacturing techniques:

ISO 9001:2015 Certified Quality System for full traceability and reliability.

CE Marking ensures compliance with international safety standards.

Precision Machining for low backlash (≤3 arcmin) and vibration (≤2.8 mm/s).

QT450 Gear Housing & Synthetic Lubrication (ISO VG 220) for long-term durability.

Design Life: ≥100,000 hours (10–15 years).

FAQs

Q1: What materials can the TH bucket elevator handle?

Answers:It handles powdery, granular, and small block materials with low abrasiveness such as cement, coal, sand, fertilizer, and grain.

Q2: What is the maximum operating temperature?

Answers:The TH bucket elevator can safely operate with materials up to 250°C.

Q3: How long does the chain last?

Answers:The forged alloy ring chains typically last 5–10 years under normal industrial working conditions.

Q4: Can it be customized for specific plant layouts?

Answers:Yes, the modular design allows for customized height, discharge method, and drive configuration.

Q5: What is the warranty period?

Answers:Senotay provides 18–24 months warranty or 2,000 operating hours, whichever comes first.