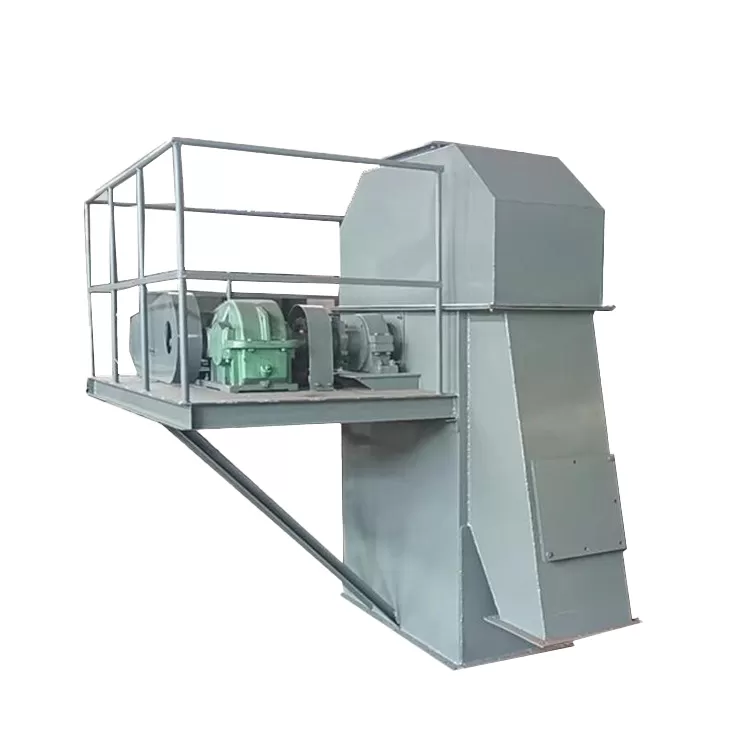

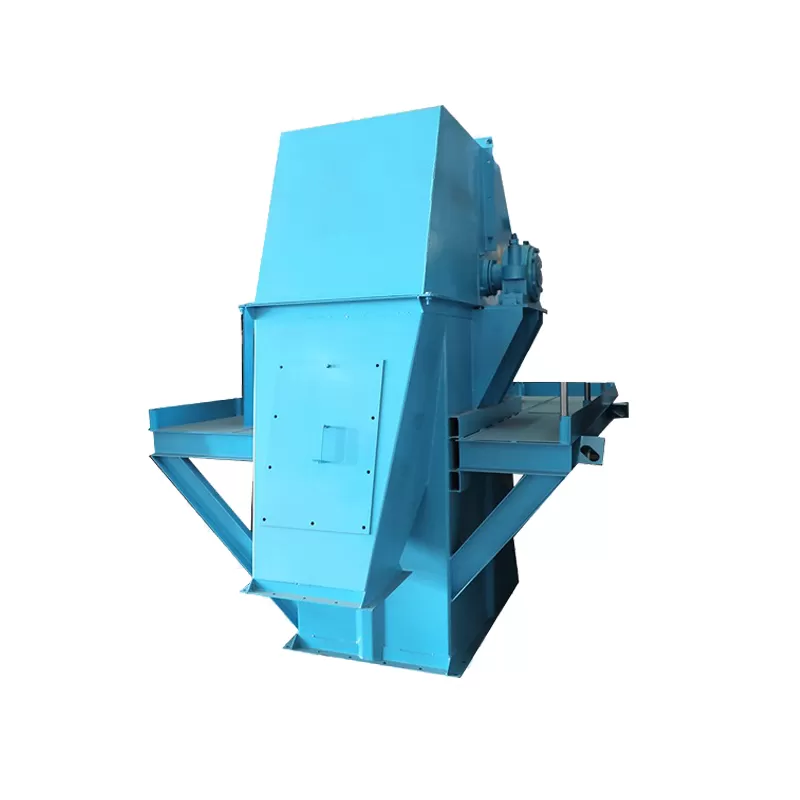

What is a TD Bucket Elevator?

The TD bucket elevator is a high-quality vertical bucket elevator system designed for transporting bulk materials such as grain, coal, cement, ore, sand and other granular or powdery materials vertically. It is specially Manufactured by Hebei OuTai Environmental Protection Equipment Co., Ltd. Which is a trusted bucket elevator supplier in China, this model is known for its reliability, efficiency, and compliance with JB3926-85 and GB standards.

With a lifting height of up to 80 meters which is the TD bucket elevator offers powerful conveying capabilities for industrial-scale operations across cement, mining, chemical, grain processing and energy sectors.

Why Choose the TD Bucket Elevator?

Choosing Senotay’s TD bucket elevator conveyor ensures superior quality, safety, and performance backed by over a decade of engineering expertise.

Here’s why global industries trust the TD series:

Compliance & Safety: Certified under JB/T 3926-1999, CE, and ISO 9001:2015 quality management systems.

Flexible Configurations: Available in belt and chain types, with conveying heights from 4m to 80m.

Durable Construction: Built with Q235 carbon steel, MN13 wear-resistant steel, or 304/316 stainless steel for long life.

Energy-Efficient: High-efficiency motors ranging from 2.2 kW to 55 kW offer low energy consumption.

Dust-Tight Design: Advanced sealing delivers 99.5% dust containment, ensuring cleaner operations.

Whether you need a standard grain elevator or a heavy-duty industrial bucket elevator, Senotay’s TD series exceeds expectations for performance and reliability.

TD Bucket Elevator Types and Specifications Table

Type No. | Hopper Form | Conveying Capacity (m³/h) | Bucket Capacity (L) | Bucket Speed (m/s) | Drum Speed (r/min) | Height (m) |

TD100 | Q/H | 4–7.6 | 0.15–0.3 | 1.4 | 67 | 4–20 |

TD160 | Q/H/ZD/SD | 9–27 | 0.49–1.9 | 1.4 | 67 | 6–35 |

TD250 | Q/H/ZD/SD | 18–36 | 1.0–2.5 | 1.6 | 61 | 10–45 |

TD315 | Q/H/ZD/SD | 28–67 | 1.95–5.8 | 1.6 | 61 | 12–50 |

TD400 | Q/H/ZD/SD | 40–110 | 3.1–9.4 | 1.8 | 55 | 15–60 |

TD500 | Q/H/ZD/SD | 63–154 | 4.84–14.9 | 1.5 | 55 | 20–70 |

TD630 | H/ZD/SD | 142–238 | 14–23.5 | 2.0 | 48 | 25–80 |

TD800 | H | 220–350 | 20 | 2.5 | 45 | 30–80 |

TD1000 | ZD | 300–550 | 25 | 2.8 | 42 | 40–80 |

TD1250 | SD | 400–750 | 30 | 3.0 | 40 | 50–80 |

TD Bucket Elevator — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Lifting Height: 5–80 m | Lifting Capacity: 15–185 m³/h | Carbon Steel Q235 / Q345 | 3–75 kW | JB3926-85, GB/T 6974, ISO 9001:2015 |

Bucket Width: 160 / 250 / 315 / 400 / 500 mm | Max Material Temperature: ≤ 250°C | Carbon Steel / Reinforced Polymer | 1.0–1.25 m/s | Yes |

Housing Thickness: 3–6 mm | Rated Load: Up to 18 t/h (powders) | Rubber Belt / Nylon-NN / Polyester-EP | ≤ 80 dB(A) | 12–24 months |

Inlet Size: DN250–DN600 | Max Input Density: ≤ 1.2 t/m³ | Cast Steel | 80–220 Nm | 25,000–40,000 hours |

Outlet Size: DN200–DN500 | Efficiency: ≥ 95% Conveying Efficiency | 45# Steel | 650–6,500 kg | > 120,000 cycles |

Section Length: 1,000–3,000 mm (modular) | Max Vertical Speed: 1.3 m/s | Heavy-duty Roller Bearings | 8–16 holes, Ø14–Ø20 mm | GB16297-1996 |

Boot Width: 400–1,000 mm | Rated Operating Pressure: ≤ 0.1 MPa | Painted / Hot-dip Galvanized | –20°C to 45°C | ISO 45001, ISO 14001 |

Boot Height: 600–1,200 mm | Bucket Filling Factor: 60–75% | Rubber Dust Seal | Top & Side Lifting Lugs | Every 6–12 months

|

Product Description & Material Properties

The TD bucket elevator features modular components engineered for longevity, safety, and high throughput. It is ideal for conveying materials with a bulk density of ≤1.5 t/m³ and temperature up to 250°C.

Material Options:

Casing Material: 3–6 mm thick carbon steel plate with modular design.

Buckets: Q235/MN13 steel or stainless steel (food-grade options available).

Belts/Chains: Multi-ply rubber belts or steel reinforced chains.

Shafts: 45# high-strength carbon steel.

Seals: Silicone or nylon brush seals ensuring dust-free performance.

Standard Physical & Mechanical Properties

Property | Description | Standard |

Tensile Strength | High-tensile rubber belts and steel chains | MT36-80 |

Operating Temperature | Up to 250°C | IEC 60034 |

Speed (RPM) | 60–85 | JB3926-85 |

Efficiency | 94–98% (gearbox) | ISO 1328-1 |

Housing | GG25–GG35 cast iron alloy | ASTM A48 |

Protection Level | IP65–IP67 | IEC 60529 |

How Does a TD Bucket Elevator Work?

The working mechanism of a TD bucket elevator involves continuous material lifting through buckets attached to a belt or chain:

Material Feeding: Material enters via gravity or a feed chute into the bottom boot section.

Elevating Action: Buckets scoop the material and move vertically upward along the casing.

Discharge: At the top head section, the material is discharged either by centrifugal force or gravity, depending on elevator type.

Return Path: Empty buckets return down through the casing to restart the cycle.

Tension Adjustment: Spring-loaded or screw-type tensioning rollers maintain optimal belt/chain alignment.

This simple yet efficient cycle ensures smooth, continuous operation with minimal spillage or blockage.

Who Uses a TD Bucket Elevator?

The TD series industrial bucket elevator is used across diverse industries, including:

Cement Plants – For clinker, limestone, and gypsum handling.

Grain Processing – Wheat, rice, corn, and cereal elevation.

Mining – For crushed ore, sand, and coal transport.

Chemical & Fertilizer – Handling powdery catalysts and raw materials.

Environmental Plants – Integrated into dust filtration and conveying systems.

Core Components

Component | Material | Function | Specification |

Buckets | Q235 / 316 SS | Material lifting | Gentle or high-speed discharge |

Belt / Chain | Rubber / Steel wire | Traction medium | Up to 250°C operation |

Drive Assembly | 45# carbon steel | Power transmission | Gear ratio 1:15–1:40 |

Casing | 3–6 mm carbon steel | Structural enclosure | Modular design |

Reducer | ZQ / ZX / YY | Speed control | Compact torque transmission |

Sealing System | Nylon/Silicone | Dust containment | ≥99.5% efficiency |

Installation Method

Foundation Preparation: Level and reinforce base structure.

Sectional Assembly: Start from the bottom boot, continue with middle housings, and finish with head assembly.

Alignment: Ensure belt/chain centering; adjust tension.

Electrical Connections: Connect motor and reducer assembly.

Trial Run: Perform empty run test to ensure stable, noise-free operation.

Technical Advantages in Manufacturing — Senotay’s Expertise

Hebei OuTai Environmental Protection Equipment Co., Ltd. (Senotay) stands out as a leading bucket elevator supplier through excellence in engineering and manufacturing:

Precision Gearboxes compliant with AGMA and ISO standards.

High-strength casings fabricated under strict CE and ISO 9001:2015 guidelines.

Robotic welding and laser cutting ensure uniform build quality.

Advanced surface treatments for corrosion and abrasion resistance.

Pre-shipment testing ensures every unit meets global industrial benchmarks.

Frequently Asked Questions (FAQs)

1. What materials can the TD bucket elevator handle?

Answes:It is suitable for powdery, granular, and small block non-abrasive or semi-abrasive materials like cement, coal, lime, sand, and grains.

2. What is the typical lifting height?

Answes:Standard models lift up to 20 m, while wire rope core types can reach 80 m.

3. Are food-grade models available?

Answes:Yes, Senotay offers 304/316 stainless steel options for food and agricultural applications.

4. How is maintenance performed?

Answes:Inspection windows and modular panels allow easy access for belt adjustment and lubrication.

5. How long is the service life?

Answes:With proper maintenance, the TD industrial bucket elevator can operate efficiently for over 10–15 years.