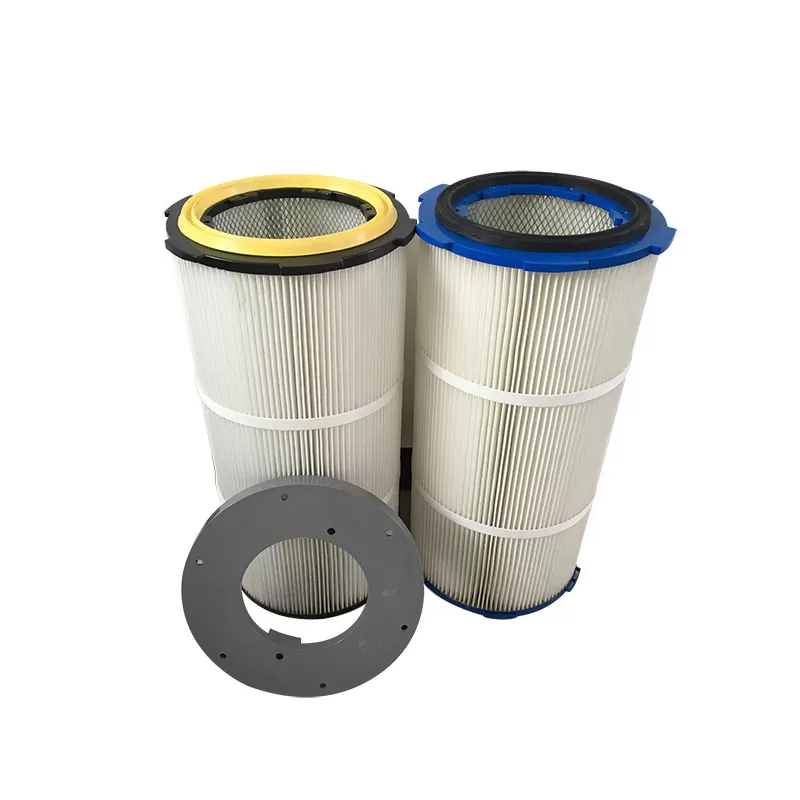

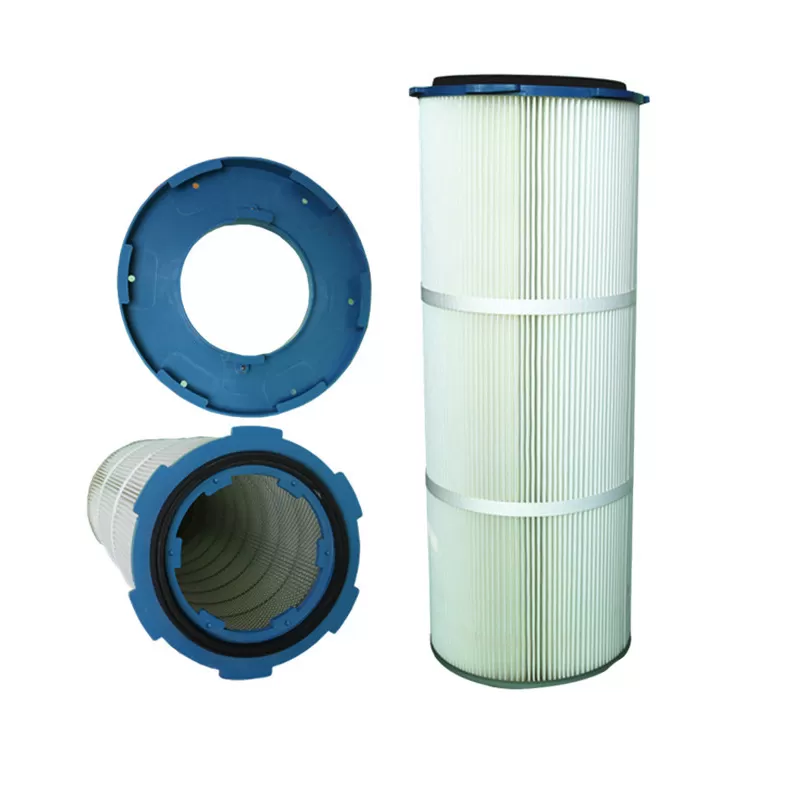

Six-Ear Quick-Release Dust Filter Element

High-Efficiency Industrial Dust Collector Filter Element for Critical Filtration

The Six-ear quick-release dust filter element is a high-performance industrial dust collector filter element engineered for demanding particulate removal applications. Designed with a secure quick-release locking system and large filtration area, this filter ensures maximum efficiency, durability, and fast maintenance. Whether you need a 325220900 dust filter element or specialized dust filter cartridges, this product delivers long-lasting reliability.

What Is a Dust Filter Cartridge?

A dust filter cartridge is a pleated filtration unit used in industrial dust collection systems to capture fine dust, fumes, and airborne contaminants. With its six-ear quick-release mechanism, this filter allows fast installation, leak-free sealing, and compatibility with a wide range of dust collector housings.

Types of Dust Filter Elements (Technical Analysis Table)

Comparison of Ten Different Filter Element Types

Type Name | Filter Media | Max Operating Temperature (°C) | Filtration Efficiency (%) | Suitable Industry |

Polyester Standard Type | Polyester | 120 | 99 | General industrial dust |

Anti-Static Safety Type | Anti-static Polyester | 120 | 99.5 | Explosion-proof environments |

PTFE Ultra-Fine Type | PTFE Coated | 150 | 99.9 | Fine powder processing |

Cellulose Economy Type | Cellulose | 90 | 98 | Woodworking & paper |

Nanofiber Ultra-High Efficiency Type | Nanofiber | 80 | 99.9 | Precision filtration |

Aramid High-Temperature Type | Aramid | 200 | 98.5 | High heat applications |

Stainless Steel Reinforced Type | Stainless Steel Mesh | 260 | 95 | High-moisture environments |

Glass Fiber Chemical Type | Glass Fiber | 300 | 99 | Chemical industry |

Polypropylene Food Grade Type | Polypropylene | 70 | 97 | Food & pharma |

Carbon Absorption Type | Carbon Impregnated | 120 | 99 | Odor & gas adsorption

|

Key Features of Our Industrial Dust Collector Filter Element

1. Enhanced Filtration Performance

· High-efficiency pleated media

· Large surface area for increased dust holding capacity

2. Six-Ear Quick-Release Design

· Easy installation and removal

· Secure locking for stable operation

3. Durable Construction

· Thick end caps, reinforced cage

· Long service life in harsh industrial environments

4. Wide Media Options

· Polyester, PTFE, anti-static, cellulose, aramid, stainless steel mesh

Technical Specifications Table

Specifications for Six-Ear Quick-Release Dust Filter Elements

Model Code | Outer Diameter (mm) | Inner Diameter (mm) | Length (mm) | Airflow Capacity (m³/h) |

M01 | 325 | 220 | 900 | 1200 |

M02 | 325 | 220 | 1000 | 1400 |

M03 | 350 | 240 | 900 | 1600 |

M04 | 320 | 210 | 850 | 1100 |

M05 | 345 | 225 | 950 | 1700 |

M06 | 300 | 200 | 600 | 900 |

M07 | 330 | 215 | 750 | 1300 |

M08 | 340 | 220 | 800 | 1500 |

M09 | 310 | 205 | 700 | 1000 |

M10 | 360 | 230 | 1000 | 1800

|

Advanced Manufacturing Process for Superior Quality

How Our 325220900 Dust Filter Elements Are Made

We follow a controlled manufacturing workflow to ensure high consistency and filtration accuracy.

Precision Pleating Technology

· Uniform pleat spacing

· Maximum filtration area without airflow restriction

Heat-Sealed Bonding & Structural Reinforcement

· Prevents bypass leakage

· Ensures stability under high pressure

100% Final Inspection

· Dimension accuracy

· Media integrity testing

· End-cap bonding strength verification

Working Principle of the Dust Filter Cartridge

How the Six-Ear Quick-Release Dust Filter Element Works

During operation, dirty air flows into the dust collector and passes through the pleated filtration media. Dust particles are captured either on the surface (surface filtration) or within the media layers (depth filtration). Clean air exits through the filter core. A pulse-jet cleaning system periodically releases compressed air to dislodge dust from the surface, ensuring consistent airflow and extended filter life.

Standard Physical & Mechanical Properties

Material & Performance Standards of Dust Filter Cartridges

· Tensile Strength: ≥ 1200 N (media dependent)

· Filtration Class: High-efficiency industrial grade

· Air Permeability: Low-pressure drop design

· Temperature Resistance: 70°C – 300°C

· Chemical Stability: Resistant to mild acids, alkalis & solvents

· Structural Durability: High rigidity, anti-collapse support

Why Choose Hebei OuTai Environmental Protection Equipment Co., Ltd.?

Leading Manufacturer of Six-Ear Dust Filter Elements

· Over 15 years of dust filtration manufacturing experience

· Full OEM customization: size, media, caps, and fitting options

· Stable global supply with competitive pricing

· Advanced automated production lines

· Strong quality assurance system and on-time delivery

· Used in cement, steel, chemical, mining, woodworking & more

Additional Section: Compatible Dust Collection Systems

Where the Six-Ear Quick-Release Dust Filter Element Fits Best

This dust filter element is compatible with:

· Pulse jet dust collectors

· Cartridge dust collectors

· Modular dust removal systems

· Central dust extraction units

· Negative pressure dust collection systems

· OEM-replacement housings for major brands

This ensures maximum installation flexibility for industrial environments with high dust loads.