What is an Oil Fume Purifier?

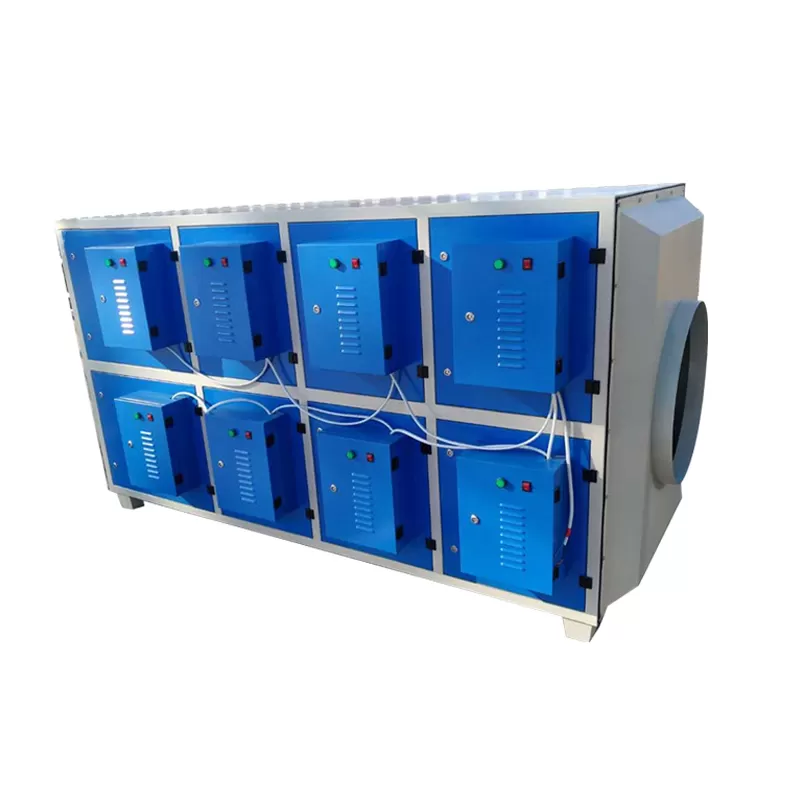

An Oil Fume Purifier which is also known as an Oil Mist Collector or Industrial Air Purifier.This oil purifier is an advanced purification system specifically engineered to capture, filter, and eliminate oil mists, fumes, VOCs also known as Volatile Organic Compounds and micro‑particles generated during industrial processes.

we Hebei OuTai Environmental Protection Equipment Co., Ltd. Also known senotay a chinese manufacturer.We design and manufacture high performance oil fume purifiers that ensure over 99% purification efficiency with safeguarding worker health and protecting equipment and also ensuring clean or compliant air emissions.

Our versatile purifiers are ideal for a wide range of applications including metalworking, machining, CNC operations, welding, kitchen exhausts, automotive painting and food processing facilities.

Some standsrds that makes Senotay Oil Fume Purifier best

As a trusted Oil Fume Purifier manufacturer we Senotay has decades of experience in environmental protection and industrial air purification. Here’s what makes our systems stand out:

Purification Efficiency: This purifier have high effieciency rate that upto 99.9% and it can Effectively removes PM2.5 sub micron oil mist and VOCs.

Custom Engineered Solutions: Tailored for airflow capacities up to 50000 m³/h to meet demanding industrial needs.

Efficient Operation: This Oilfume purifier is designer aerodinamacaly.Its Aerodynamic airflowdesign with low noise levels less than 70 dB and energy consumption of only 0.5 kW/1000 m³.

Long Durability: Its Constructed from corrosion resistant stainless steel and high grade insulating materials for a long service life morethan 100,000 hours.

24/7 Technical Support + 2-Year Comprehensive Warranty: we are Providing reliable after sales service across all installations.

Certified Quality: This purifier Manufactured under ISO 9001 with CE and UL standards.It is fully compliant with environmental regulations.

Oil Fume Purifier — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Overall Length: 600–1,800 mm | Airflow Capacity: 1,000–20,000 m³/h | Housing Material: Q235 CS / SS304 (opt.) | Power Supply: 380 V / 50 Hz | Service Life: 10–15 years |

Overall Width: 450–1,200 mm | Purification Efficiency: ≥ 99% | Pre-Filter Media: Aluminum Mesh | Installed Power: 0.75–7.5 kW | ISO 9001:2015 |

Overall Height: 800–2,500 mm | Particle Removal Size: ≥ 0.3 μm | Main Filter: Fiberglass / HEPA H13 | Fan Speed: 1,450–2,900 rpm | CE Certified |

Inlet Flange Diameter: Φ150–Φ500 mm | Oil Mist Removal: ≥ 98% | Final Filter: Activated Carbon | ≤ 75 dB(A) | ISO 14001 |

Outlet Flange Diameter: Φ150–Φ500 mm | VOC Removal Efficiency: ≥ 95% | Seal Material: NBR / Silicone | Operating Temp.: –10 to 80°C | GB/T 16297 |

(BCD): Φ180–Φ560 mm | Pressure Drop (Initial): 800–1,200 Pa | Impeller Material: Carbon Steel / Aluminum | Max Oil Concentration: ≤ 200 mg/m³ | EPA / Local Emission Std. |

Mounting Base Size: 500×500–1,500×1,200 mm | Pressure Drop (Max): ≤ 1,800 Pa | Filter Frame: Galvanized Steel | 80–850 kg | Filter Life: 6,000–12,000 hrs |

Drain Port Size: DN25–DN50 | Leakage Rate: ≤ 1% | Fasteners: Grade 8.8 Bolts | Drain Method: Auto / Manual | Maintenance Cycle: 3–6 months |

Types of: Oil Fume Purifier

Model Type | Airflow (m³/h) | Efficiency (%) | Pressure (Pa) | Power (kW) | Noise (dB) | Filter Stages | Best Use Case |

OFP‑500 | 500 – 800 | 99.3 | 500 | 0.37 | 58 | 3 | Small machinery fumes |

OFP‑1000 | 1,000 – 1,500 | 99.4 | 750 | 0.55 | 60 | 3 | CNC oil mist collection |

OFP‑2000 | 2,000 – 3,000 | 99.5 | 1,000 | 0.75 | 62 | 4 | Multi‑station automation lines |

OFP‑3000 | 3,000 – 4,500 | 99.6 | 1,200 | 1.1 | 64 | 4 | Welding shop air cleaning |

OFP‑5000 | 5,000 – 7,500 | 99.7 | 1,500 | 1.5 | 66 | 5 | Industrial processing zones |

OFP‑8000 | 8,000 – 12,000 | 99.8 | 2,000 | 2.2 | 68 | 5 | Large central air systems |

OFP‑12000 | 12,000 – 18,000 | 99.9 | 2,500 | 3.0 | <70 | 6 | Food processing plants |

OFP‑20000 | 18,000 – 25,000 | 99.9 | 2,800 | 5.5 | <70 | 6 | Industrial factories |

OFP‑25000 | 25,000 – 30,000 | 99.95 | 3,000 | 7.5 | <70 | 7 | Heavy‑duty forging lines |

OFP‑30000 | 30,000 + | > 99.95 | 3,200 | 11 – 18.5 | <72 | 7 | Large plant purification |

Product Description & Material Properties

Our Oil Fume Purifiers are modular systems integrating filters, ESP (electrostatic precipitator) units, fans, and optional deodorizing stages. Built with robust metal casing (IP54 rated) and easy‑clean filter modules, they deliver stability and top‑tier purification under demanding operating environments.

Property | Specification |

Material of Construction | Stainless Steel / Powder-Coated Carbon Steel |

Surface Finish | Anti‑corrosion baked enamel; high‑gloss industrial durability |

Operating Temperature | −20 °C ~ 80 °C |

Filtration Stages | 2 to 5 (Pre‑filter, ESP, HEPA, Carbon, UV) |

Voltage | 380 V / 3‑Phase |

Efficiency | ≥ 99.9 % for PM2.5 |

Airflow Capacity | 500 ~ 30,000 m³/h |

Noise Level | < 70 dB(A) |

Service Life | Up to 100,000 hours |

Certifications | ISO 9001, CE, UL |

Oil Fume Purifier Working Mechanism

The Senotay Oil Mist Collector utilizes a multi‑stage purification process to ensure complete pollutant removal:

Air Intake: In air intae process here Polluted air is drawn in via ducts or capture hoods.

Pre Filtration: Here this step Heavier droplets and coarse oily particles are removed using inertia separation or mesh filters.

Electrostatic Precipitation (ESP): In esp process Ultrafine oil aerosols are charged and collected on high‑voltage plates.

Activated Carbon Stage (Optional):In this process Adsorbs VOCs, odor and hydrocarbon vapors.

Clean Air Discharge: Filtered air is exhausted safely or recirculated into the workspace.

This five‑step mechanism guarantees maximum air purification with minimum pressure drop, enhancing the operating efficiency of your plant.

Core Components

Inlet & Hood System: Here in this indutry it Captures fumes directly from the source.

Pre‑Filter Section: It Removes large oil droplets.

Electrostatic Precipitator Cells: It Charges and traps fine mist particles.

Activated Carbon Filter (Optional): Absorbs odor and vapor.

Fan / Blower Assembly: Provides steady airflow.

Control Panel: Smart PLC system with voltage and fault monitoring.

Outer Housing: Dust‑proof, sealed cabinet design ensuring mechanical integrity.

Installation Method

Senotay Oil Fume Purifiers can be installed in several ways depending on site conditions:

Standalone Units: Near emission sources such as CNC machines or fryer hoods.

Ducted Centralized Systems: Connected via ducts for multi‑point extraction.

Wall or Ceiling Mounted Systems: For space‑saving layouts.

Integrated OEM Installation: Built directly into manufacturing lines.

Technical Advantages in Senotay Manufacturing

At Hebei OuTai Environmental Protection Equipment Co., Ltd., our manufacturing incorporates advanced electrostatic field design, precision high‑voltage power modules, and IoT-based monitoring systems. This guarantees:

Stable high-voltage output for efficient particle charging

Smart power regulation with overload & short‑circuit protection

Low ozone emission (< 0.05 ppm) for environmental safety

Optimized aerodynamic structure for low resistance (< 250 Pa pressure drop)

Comprehensive quality checks under ISO 9001 standards

Our automated assembly lines and in-house test rigs ensure every Oil Mist Collector delivers maximum lifespan and consistent performance.

Frequently Asked Questions (FAQ)

1. What is the efficiency of Senotay Oil Fume Purifier systems?

Answers:Our oil mist collectors achieve ≥ 99% removal efficiency for oil smoke, fumes, and PM2.5 particles.

2. Do Oil Fume Purifiers require frequent maintenance?

Answers:No. The ESP cells are permanent and washable, and other filter modules have extended service life (HEPA 12 months, carbon 6 months).

3. What after‑sales service is provided?

Answers:offers 24/7 technical support and a two‑year warranty with spare parts availability.

4. Can these purifiers handle different air volumes?

Answers:Yes It can. Models range from 500 m³/h to 50,000 m³/h, suitable for both standalone and centralized setups.

5. Is your system environmentally friendly?

Answers:Absolutely. Our equipment meets CE, UL and ISO 9001 standards with ultralow ozone output (< 0.05 ppm).