What Is an Oblique-Insert Dust Filter Element?

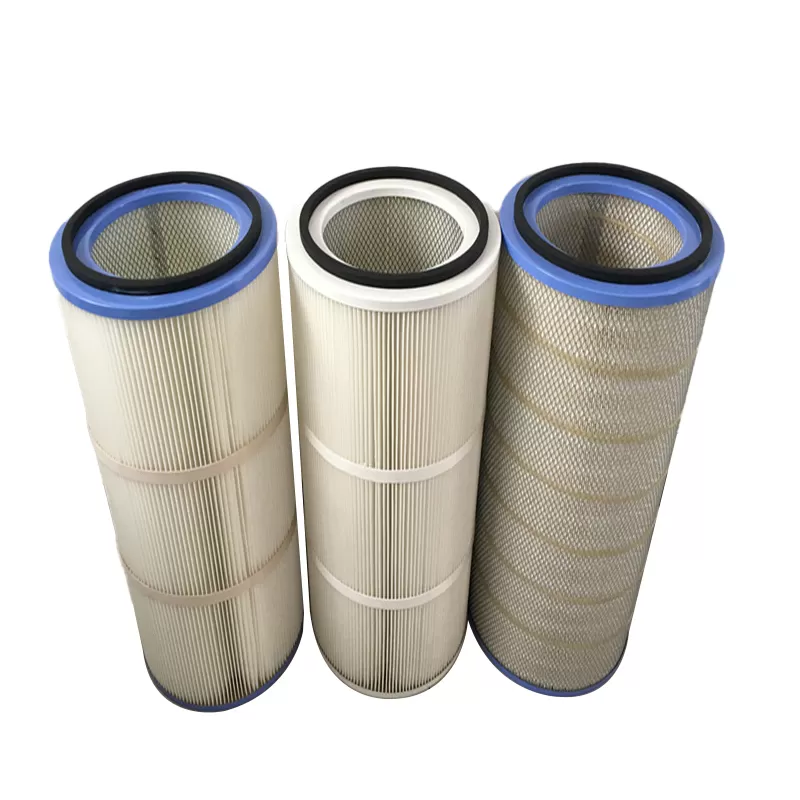

An Oblique-insert Dust Filter Element is a specialized air filtration component designed for use in industrial dust collection systems. Unlike standard vertically installed filters, this element is mounted at an oblique (angled) position, optimizing space utilization and improving air distribution within the dust collector.

The oblique installation design enhances dust release, simplifies maintenance, and ensures high filtration efficiency even in compact system layouts. As a leading Dust Filter Element Manufacturer, Senotay provides superior-quality oblique-insert filters engineered for durability, precision, and long-lasting performance.

Why Oblique-Insert Dust Filter Element Is Important for Dust Collection Systems

The oblique-insert structure addresses common challenges in traditional filter designs such as difficult replacement, space limitations, and uneven airflow distribution. It is essential for maintaining clean air quality, protecting equipment, and enhancing plant efficiency.

Key reasons this filter is vital:

• Space-Saving Design: Suitable for dust collectors with limited height or width.

• High Filtration Efficiency: Removes up to 99.9% of dust particles as small as 0.3 microns.

• Stable Operation: Reduces system air resistance and turbulence losses.

• Extended Service Life: Designed for continuous operation under harsh industrial conditions.

• Environmental Compliance: Meets international air quality and emission standards.

Types of Oblique-Insert Dust Filter Elements

Type No. | Filter Media | Diameter (mm) | Length (mm) | Filtration Efficiency | Max. Temp (°C) | Connection Type | Typical Application |

OIDE-01 | Polyester | 100 | 300 | 99.8% | 120 | Oblique Thread | Woodworking |

OIDE-02 | Cellulose | 120 | 320 | 98.5% | 100 | Clamp-on | Cement Factory |

OIDE-03 | PTFE-coated | 110 | 340 | 99.99% | 150 | Screw Thread | Chemical Plant |

OIDE-04 | Nanofiber | 125 | 350 | 99.95% | 130 | Oblique Insert | Pharmaceutical |

OIDE-05 | Polypropylene | 130 | 380 | 98% | 90 | Bayonet Lock | Food Processing |

OIDE-06 | Antistatic Polyester | 140 | 400 | 99.9% | 110 | Slanted Mount | Metal Fabrication |

OIDE-07 | PTFE + Stainless Mesh | 150 | 420 | 99.99% | 180 | Oblique Thread | High-temp Filtration |

OIDE-08 | Synthetic Fiber | 160 | 440 | 99.5% | 100 | Clamp Seal | Foundry |

OIDE-09 | Polyester Felt | 170 | 460 | 99% | 120 | Quick-Fit Thread | Paint Booth |

OIDE-10 | Laminated Media | 180 | 480 | 99.9% | 200 | Slanted Clip | Steel Industry |

Material Properties of Oblique-Insert Dust Filter Element

Our filters are manufactured using premium-grade materials that ensure superior mechanical and thermal strength. The main materials include:

Filter Media: Imported spunbond polyester, cellulose, PTFE-coated fabrics, nanofiber composites.

End Caps: Galvanized or stainless steel, corrosion-resistant.

Center Core: Perforated or expanded metal for rigidity and airflow support.

Seal Rings/O-Rings: Silicone or polyurethane for dust-tight sealing.

These materials ensure chemical resistance, temperature stability, and consistent filtration performance under high-pressure working conditions.

Standard Physical & Mechanical Properties of Oblique-Insert Dust Filter Element

Property | Standard Value / Description |

Filtration Efficiency | Up to 99.99% for particles ≥ 0.3 µm |

Operating Temperature | -20°C to +120°C (customized versions up to 150°C) |

Air Permeability | 150–250 L/m²·s depending on media type |

Burst Pressure | ≥ 2500 Pa |

Moisture Resistance | Excellent (hydrophobic media optional) |

Service Life | 8,000 – 12,000 hours (standard usage) |

Cleaning Method | Pulse-jet or reverse air cleaning |

Core Component

Filter Media (Pleated Layer) – Traps and holds dust particles effectively.

Outer Mesh Support – Protects the filter from collapse due to air pressure.

Center Tube/Core – Provides structural rigidity and optimized airflow.

End Caps – Seal the filter ends, ensuring stable air channels.

Oblique Insert Mount – Allows angled installation for enhanced air distribution.

Rubber Gaskets – Prevent air leakage and ensure tight sealing.

Working Mechanism

The Oblique-Insert Dust Filter Element operates by drawing contaminated air into the filter system. The air is forced through the pleated filter media where dust particles are trapped on the surface or within its depth. Clean air flows out through the inner core, and pulse jet cleaning periodically removes the accumulated dust.

The oblique angle design promotes natural dust shedding through gravity, improving filter regeneration and reducing the frequency of maintenance cycles.

Oblique-Insert Dust Filter - Model OID-45°

Core Specification | Performance Metric | Material & Build | Installation Data | Service Life |

Insertion Angle: 45° | Flow Rate: 850 m³/h | Housing: 304 Stainless | Torque: 45 Nm | Service: 6,000 hrs |

Length: 457 mm | Efficiency: 99.95% | Media: Nano-fiber | Seal: Viton O-ring | Warranty: 24 mo |

Diameter: 89 mm | Pressure: 10 Bar | End Caps: PPS | Weight: 3.8 kg | Cleaning: 5 cycles |

Port Size: DN80 | Temp Max: 120°C | Gasket: EPDM | Tools: Standard | DP Max: 0.8 Bar |

Thread: G2" | Test: 15 Bar | Mesh: 316SS | Orientation: Horizontal | Replace: Visual |

Element Type: Pleated | Initial DP: 150 Pa | Support: Perforated | Bolt Size: M10 | Storage: 36 mo |

Media Area: 2.8 m² | Final DP: 2500 Pa | Coating: Epoxy | Flange: ANSI 150 | Cycle Life: 500k |

Weight: 3.8 kg | Rating: 5 µm | Cage: 304 SS | Lift Points: 2 | MTBF: 25k hrs |

Seals: Double | Burst: 25 Bar | Gauge: 1.2 mm | Height: 520 mm | Cost: $285 |

Finish: Electro | Flow Max: 950 | Rigging: Eye | Access: Top | Lead Time: 5d |

Main Features of Oblique-Insert Dust Filter Element

(Oblique Insertion Design): Easy installation and maintenance.

High Filtration Efficiency: Up to 99.9% particle removal rate.

Optimized Air Flow: Even air distribution prevents dust accumulation.

Durability: Resistant to heat, moisture, and chemical corrosion.

Customizable: Available in various dimensions, materials, and end-fitting types.

Eco-Friendly: Reusable and recyclable components extend product life.

Why Oblique-Insert Dust Filter Element Is the Right Choice

· Efficient Air Management: Angled structure provides superior dust removal and air distribution.

· Extended Filter Life: Resistant to clogging, moisture, and thermal stress.

· Safety & Reliability: Suitable for applications with conductive and combustible dust.

· Low Maintenance Cost: Quick-change design saves labor and downtime.

Industrial Classification of Filter Elements

Industry | Recommended Filter Type | Media Type | Operating Condition |

Cement | OIDE-04, OIDE-06 | Polyester, PTFE | High dust concentration |

Metal Manufacturing | OIDE-06, OIDE-07 | Antistatic Polyester | Combustible dust environments |

Chemical | OIDE-03, OIDE-04 | PTFE, Nanofiber | Corrosive gases |

Food & Beverage | OIDE-05 | Polypropylene | Hygienic and waterproof |

Wood & Paper | OIDE-01, OIDE-02 | Polyester | Fine dry dust |

Power Generation | OIDE-07, OIDE-10 | PTFE + Mesh | High-temperature applications |

Manufacturing Process of Oblique-Insert Dust Filter Element

1. Media Preparation

→ Roll-to-roll inspection (thickness, permeability, tensile)

→ Laser cutting for precise pleat width

2. Oblique-Optimized Pleating

→ CNC pleater with adjustable angle guides

→ Pleat spacing optimized for angled stress distribution

3. Top End Cap Molding

→ Injection-molded polyurethane with integrated chamfer (20° standard)

→ Embedded sealing groove + alignment ribs

4. Bonding & Curing

→ Hot-melt adhesive (no VOCs)

→ 24-hour post-cure for bond strength

5. Quality Control

→ Dimensional scan (OD, length, chamfer angle ±1°)

→ Pulse durability (≥8,000 cycles @ 7 bar)

→ Leak test (0.3 µm DOP aerosol challenge)

6. Packaging

→ Individual PE sleeve + rigid divider

→ Palletized with tilt indicator

FAQs

Q1: What makes the oblique-insert design better than standard vertical filters?

A1: The angled installation improves airflow and dust shedding, minimizing dust buildup and reducing cleaning frequency.

Q2: Can I custom-design the filter element for my equipment?

A2: Yes, customized dimensions, media, and fittings are available based on your industry or dust collector model.

Q3: How long does it last?

A3: Average lifespan ranges from 8,000–12,000 operating hours, depending on dust load and cleaning cycles.

Q4: Which industries benefit most from these filters?

A4: Cement, metalworking, power plants, woodworking, chemical processing, and food production sectors.

Q5: Are your filters certified?

A5: Yes, all HEBEIOUTAI dust collector filters comply with ISO and CE standards, ensuring global quality reliability.