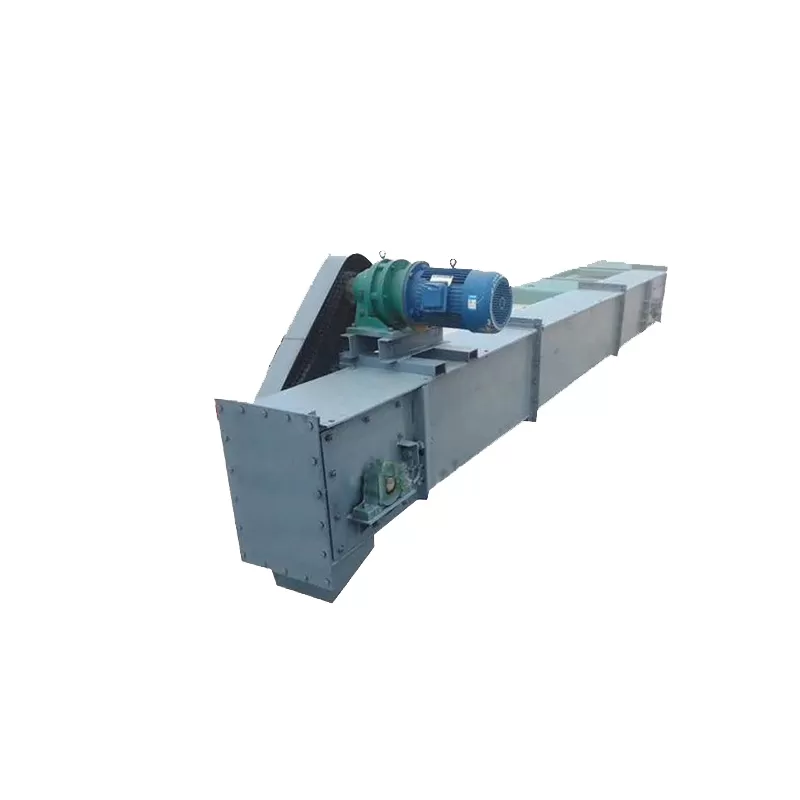

What Is an MS Chain Conveyor?

MS Chain Conveyor which is also known as a buried scraper conveyor, enclosed chain conveyor or drag conveyor.It is a highly efficient bulk material conveyor that specially designed for continuous and reliable transport of granular and powdered materials. This traditional belt systems MS type buried scraper conveyors operate using high-strength alloy drag chains that move materials along a sealed trough that preventing spillage, minimizing dust and ensuring a clean working environment.

This MS series chain conveyor is engineered by Hebei OuTai Environmental Protection Equipment Co., Ltd. Also known as Senotay.This industrial chain conveyor meets ISO 9001:2015 and CE safety standards which ensuring durability, reliability and long service life for demanding operations in mining, grain, cement and chemical industrie.

Some reason that why you Choose MS Chain Conveyor?

Choosing an MS Chain Conveyor means choosing efficiency, reliability and environmental compliance. Our Senotay MS models are designed to provide 99% operational availability while reducing maintenance costs by up to 40% compared to conventional conveyors. With a sealed structure dust containment up to 99.2%, and wear-resistant troughs, these conveyors guarantee consistent performance in heavy-duty, dusty and hazardous environments.

Here some Key Advantages:

This syetem have High conveying capacity upto 50–600 m³/h for large scale operations.

Its enclosed design ensuring minimal dust and contamination.

The system made with some durable material that’s Long life components reducing downtime.

It have also flexible horizontal or inclined installation up to 30°.

It have Power efficiency upto 15–30% lower energy consumption.

The system is ideal for bulk materials like coal, cement, grain and fertilizer.

MS Chain Conveyor Types — Specification Comparison

Model | Capacity (m³/h) | Max Length (m) | Tilt Angle (°) | Chain Type | Motor Power (kW) | Weight (kg/m) |

MS20 | 50 | 40 | <15° | TG100 | 5.5 | 7.8 |

MS25 | 60 | 40 | <15° | TG100 | 7.5 | 12.2 |

MS32 | 80 | 40 | <15° | TG100 | 11 | 35 |

MS40 | 120 | 60 | <15° | TG100 | 15 | 43.2 |

MS50 | 150 | 70 | <20° | TG125 | 18.5 | 52 |

MS63 | 200 | 70 | <20° | TG125 | 22 | 60 |

MS80 | 300 | 80 | <25° | TG150 | 30 | 68 |

MS100 | 400 | 100 | <30° | TG150 | 45 | 75 |

MS125 | 500 | 120 | <30° | TG175 | 55 | 88 |

MS150 | 600 | 150 | <30° | TG175 | 75 | 95 |

MS Chain Conveyor – Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Length: 3,000–80,000 mm | Operating Pressure: 0.3–1.2 Bar | Q235 / Q345 Carbon Steel | 250–620 Nm | 10–18 years |

Width (Trough): 160–800 mm | Max Pressure: 1.6 Bar | 40Cr / 20CrMnTi Alloy Steel | 300–4,500 kg | 25,000–40,000 hrs |

Height: 260–1,200 mm | Operating Temp: –10 to 120 °C | Q235 / Polymer | 12–20 holes, Ø14–22 mm | 12–20 months |

Inlet Size: 200–700 mm | Max Temp: 150 °C | UHMW-PE / NM400 | 2–6 reinforced pads | ISO 9001:2015 / CE |

Outlet Size: 250–750 mm | Capacity: 10–250 m³/h | CS / SS304 | 0.15–0.45 m/s | JB/T 3926 |

Flange Size: Ø200–Ø850 mm | Conveyor Efficiency: 88–95 % | 100–250 mm | 3–45 kW | EN 619 |

BCD: Ø160–Ø810 mm | Max Conveyor Angle: 0–25° | 4–10 mm | ≤ 2.8 mm/s | Every 1,500–2,000 hrs

|

Product Description & Material Properties

Senotay’s MS Chain Conveyor system is built to handle a wide range of bulk materials — from dense minerals to lightweight grains — in both horizontal and inclined orientations.

Standard Physical & Mechanical Properties

Property | Details |

Conveying Capacity | 50–600 m³/h (depending on density & configuration) |

Conveying Length | 5–70 meters (customizable) |

Inclination Capability | Up to 30° |

Bulk Density Range | 0.4–0.8 t/m³ |

Power Requirements | 5.5–75 kW |

Material Options | Carbon Steel, SS304, SS316 |

Dust Containment Efficiency | 99.2% |

Noise Level | < 75 dB(A) |

How Does an MS Chain Conveyor Work?

An MS Chain Conveyor works using a continuous chain and flight system that drags material through a sealed trough. The drag chain carries the material from the inlet to the discharge point while ensuring complete control and minimal degradation.

Working Mechanism:

Material Loading: Bulk materials enter the inlet chute or hopper.

Chain Movement: The drive station powers the drag chain and flights, propelling the material along the enclosed channel.

Controlled Transport: Scrapers push materials forward efficiently with minimal turbulence.

Material Discharge: The product exits through the outlet at a controlled flow rate.

Return Path: The chain returns via an enclosed lower channel, ready for another cycle.

This drag-and-scrape motion provides excellent control even at steep inclines, making it ideal for underground coal mines and grain silos.

Who Uses an MS Chain Conveyor?

The MS type buried scraper conveyor is widely used in:

Coal Mining: For continuous coal haulage and shearer positioning.

Grain Processing: Safe transport of wheat, corn, and soybeans.

Cement & Fertilizer Plants: Handling powders and granules.

Power Generation: Conveying fly ash and bottom ash.

Chemical & Metallurgical Industries: Moving bulk powders under controlled conditions.

Key Features of the MS Chain Conveyor

Fully enclosed construction for dust-free, environmentally friendly operation.

High-capacity conveying suitable for dense or abrasive materials.

Low operating noise (< 75 dB) and vibration.

Minimal maintenance with quick-access inspection covers.

Supports horizontal, vertical, and inclined layouts.

Customizable inlet and outlet flanges (DN150–DN400).

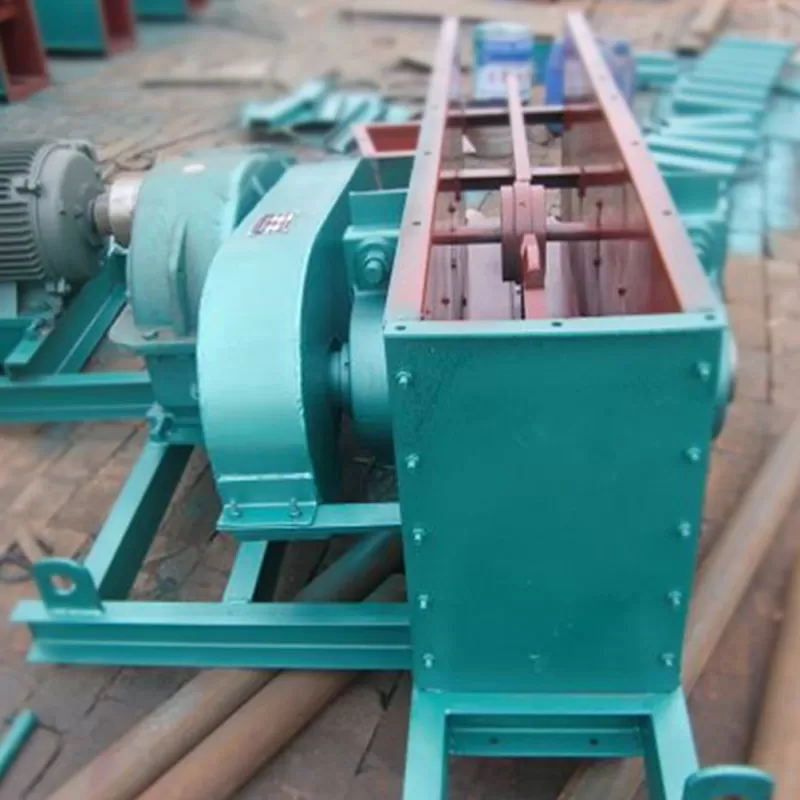

Core Components

Component | Specifications | Expected Lifespan | Key Benefits |

Drag Chain & Flights | High-strength alloy steel, welded flights | 3–8 years | Superior tensile strength & reliability |

Trough & Covers | 4–8 mm steel; reinforced crossmembers | 10–15 years | Rigid, dust-proof enclosure |

Drive Station | IE3/IE4 motors, safety couplings | 5–10 years | Energy-efficient operation |

Bearings & Seals | Double-lip seals, SKF/FAG bearings | 2–5 years | Smooth rotation and minimal leakage |

Inlet/Outlet Systems | DN150–DN400 flanges | 10+ years | Seamless integration & flexible installation |

Installation Method

Installation of the MS Chain Conveyor system involves:

Foundation Preparation: Aligning base frames and supports.

Modular Assembly: Connecting trough sections with sealing flanges.

Chain Installation: Mounting drag chains and adjusting tension.

Drive Unit Setup: Coupling motor and sprockets with torque-limiting devices.

Testing & Commissioning: Performing trial runs and checking efficiency.

Senotay provides on-site technical support and custom layout designs for a seamless installation process.

Technical Advantages in Manufacturing — Why Senotay?

As a leading chain conveyor manufacturer in China, Hebei OuTai Environmental Protection Equipment Co., Ltd. (Senotay) integrates advanced design, strict quality control, and precision engineering to ensure every conveyor meets international standards.

Senotay’s Technical Edge:

Certified with ISO 9001:2015 and CE.

Premium steel fabrication ensures longevity and safety.

Energy-efficient drive technology reduces operational cost.

Smart dust containment (99.2% efficiency).

Comprehensive after-sales support with 24/7 technical assistance.

FAQs: MS Chain Conveyor

Q1: What materials can the MS Chain Conveyor handle?

Answers: It is suitable for coal, cement, grain, chemicals, and fertilizers — essentially all bulk materials with densities between 0.4–0.8 t/m³.

Q2: How long does an MS Chain Conveyor last?

Answers: The overall system lifespan is 10–15 years, with individual parts lasting 2–8 years depending on conditions.

Q3: Is the system customizable for length or height?

Answers: Yes, Senotay designs and fabricates custom chain conveyor systems up to 70 meters long with inclination up to 30°.

Q4: How does it improve environmental safety?

Answers: Its fully enclosed design ensures 99.2% dust containment, ideal for clean and safe industrial environments.

Q5: What services does Senotay provide?

Answers: From design consultation, on-site installation, to after-sales maintenance, Senotay provides complete turnkey conveying solutions.