What is an LS Screw Conveyor?

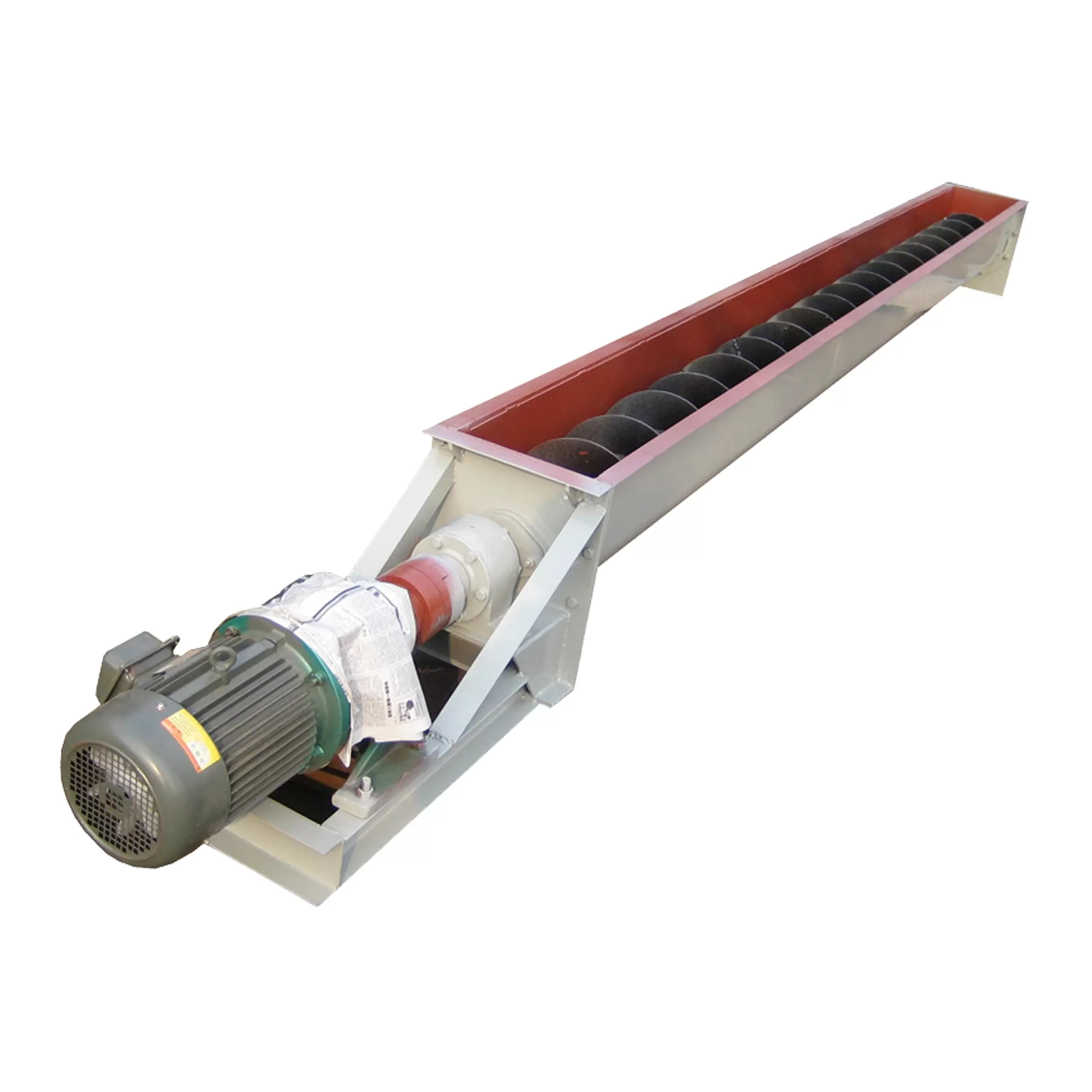

The LS Screw Conveyor whichvengineered by Hebei OuTai Environmental Protection Equipment Co., Ltd. is a next-generation auger conveyor system developed from the GX model, offering enhanced reliability, long service life, and exceptional adaptability. Designed and manufactured under the JB/T 7679-95 “Screw Conveyor” standard, the LS series excels in the efficient handling of powdery, granular or small pieces of materials such as cement, ash, grain, coal, or sand.

The LS Screw Conveyor is CE and ISO 9001:2015 certified thats providing trusted quality assurance and safety compliance for global industrial applications.

Why Choose the LS Screw Conveyor?

As an ISO & CE-certified screw conveyor supplier in China, Senotay delivers systems that balance efficiency, reliability, and customization. The LS Screw Conveyor stands out due to:

High Reliability & Durability – Engineered for 15–20 years of service life under normal industrial conditions.

Flexible Configuration – Available in diameters from 100 mm to 1250 mm, with conveying lengths from 4 to 70 meters.

Energy Efficiency – Equipped with high-torque, low-vibration reducers and optimized motor systems for smooth, quiet performance.

Strong Adaptability – Effective for both horizontal and inclined transport (≤45°), suitable for multiple industrial environments.

Global Safety & Quality Standards – Complying with CE, ISO, and RoHS certifications, ensuring environmental and operational safety.

Types of LS Screw Conveyors: Models & Specifications

Model | Screw Diameter (mm) | Pitch (mm) | Speed (r/min) | Capacity (m³/h) | Length (m) | Motor Power (kW) |

LS100 | 100 | 100 | 140 | 2.2 | 4–10 | 0.55–1.1 |

LS160 | 160 | 160 | 112 | 9.7 | 6–15 | 1.5–3 |

LS200 | 200 | 200 | 100 | 16.9 | 6–20 | 2.2–4 |

LS250 | 250 | 250 | 90 | 29.7 | 8–25 | 3–5.5 |

LS315 | 315 | 315 | 80 | 52.9 | 10–30 | 4–7.5 |

LS400 | 400 | 355 | 71 | 85.3 | 15–40 | 5.5–11 |

LS500 | 500 | 400 | 63 | 133.2 | 20–50 | 7.5–15 |

LS630 | 630 | 450 | 50 | 188.9 | 25–60 | 11–22 |

LS800 | 800 | 500 | 40 | 270.7 | 30–70 | 15–30 |

LS1000 | 1000 | 560 | 32 | 379.0 | 40–70 | 22–45 |

LS Screw Conveyor — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Conveyor Length: 2,000–60,000 mm (modular sections) | Design Capacity: 12–420 m³/h (model-dependent) | Carbon Steel (Q235B) / SS304 / SS316L | 120–680 Nm | 30,000–50,000 hours (typical) |

Outer Diameter: 100–630 mm | Max Operating Pressure: ≤ 1.5 Bar | Q235B / SS304 | 50–120 rpm | CE Certified |

Trough Width: 160–720 mm | Max Operating Temperature: 80°C (standard) | Cast Steel | Ø14–Ø22 mm holes on 4–12-hole flanges | ISO 9001:2015 |

Overall Height: 300–1,150 mm | Maximum Temperature (High-Temp Option): 180°C | 45# Steel / SS304 | 95–2,300 kg (size-dependent) | JB/T 7679-95 |

Flange Size: Ø200–Ø900 mm | Material Bulk Density Range: 0.4–2.0 t/m³ | NBR / EPDM / PTFE | Reinforced eye-bolts (2–6 per unit) | 500–800 cycles/year |

(BCD): Ø170–Ø860 mm | Efficiency: 85–92% (conveying efficiency) | Bolt-on dustproof steel cover | 0°–45° | IP55 (motor/drive) |

Inlet Size: 150–600 mm | Flow Rate Range: 60–85% of max capacity | Standard ≥ 3.2 µm Ra | ≤ 75 dB(A) | EN 619 & CE Machinery Directive |

Product Description

Property | Specification |

Product Name | LS Screw Conveyor |

Design Standard | JB/T 7679-95 |

Certification | ISO 9001:2015, CE |

Conveying Capacity | 2.2 m³/h ~ 500+ m³/h |

Temperature Range | Material ≤ 200°C, Ambient –20°C to +50°C |

Material Options | Q235 Carbon Steel, 45# Steel, Stainless Steel (Optional) |

Surface Treatment | Anti-corrosion paint / powder coating / wear-resistant lining |

Drive Motor Power | 0.55 kW – 55 kW (depending on model size) |

Reducer Type | XWD Cycloidal Pinwheel Reducer (Efficiency > 90%) |

Material Properties & Standard Physical / Mechanical Properties

Component | Material Composition | Mechanical Property | Feature |

Screw Shaft | Q235 / 45# Carbon Steel | High torsional strength | Supports heavy loads; long lifespan |

Flight Blades | Helicoidal flighting | Wear-resistant | Optional hardened edges for abrasive material |

Casing / Trough | 4–6 mm Carbon Steel Plate | High rigidity | Dust-tight, vibration-resistant |

Bearings | Self-lubricating alloy | Low friction coefficient | Extended service life |

Seals | Triple-lip / labyrinth design | IP65–IP67 | Prevents dust leakage and lubricant loss |

How Does an LS Screw Conveyor Work?

The working mechanism of the LS Screw Conveyor follows a simple yet highly effective principle:

Material Feeding: Bulk materials are introduced through a controlled inlet via gravity or a hopper.

Conveying Action: The rotating screw blades (20–120 RPM) move materials along the enclosed U-trough or tubular casing.

Friction and Weight: The weight and casing friction prevent bulk materials from rotating with the auger blades, ensuring continuous forward movement.

Discharge: Material exits through a designated outlet for further processing or packaging.

Dust Control: The enclosed design ensures zero spillage and dust emission, maintaining workplace cleanliness.

Features of the LS Screw Conveyor

Low noise operation (≤78 dB).

Modular structure for easy maintenance and installation.

Excellent sealing—ideal for cement screw conveyor applications.

High-efficiency drive system (up to 98%).

Anti-clog design for smooth flow.

Customizable inlets/outlets to fit existing systems.

Core Components

Screw Shaft & Flighting: Helicoidal flight with a 1:1 pitch ratio for optimal material flow.

U-Trough & Casing: 4–6 mm thick carbon steel casing with a labyrinth cover seal.

Drive Unit & Reducer: XWD-type cycloidal reducer with ≥90% efficiency.

Intermediate Bearings: Self-lubricating design for minimal wear and downtime.

Sealing System: High-precision triple-lip seals and gasketed joints for dust protection.

Flexible Ports: Flanged inlet/outlet for various operating configurations.

Installation Method

Horizontal Installation: For short-distance or gentle material transfer.

Inclined Setup: Configurable up to 45° with pitch adjustment.

Hanging Supports: Utilized for screw conveyors over 6 meters long.

Anchored Foundation: Ensures vibration-free, safe operation.

Flexible Inlet Placement: Compatible with silo, hopper, or pneumatic feed systems.

Technical Advantages in Manufacturing by Senotay

At Senotay (Hebei OuTai Environmental Protection Equipment Co., Ltd.), every LS Screw Conveyor undergoes:

Strict Quality Control – ISO 9001:2015-certified processes.

Precision Fabrication – CNC machining and robotic welding for perfect alignment.

Surface Protection – Anti-rust, anti-abrasion coatings for long-term use.

Testing & Compliance – CE, ATEX, and RoHS certified for global market acceptance.

Customization Options – Explosion-proof, high-temperature-resistant, and stainless-steel variants.

FAQs About LS Screw Conveyor

Q1. What materials can an LS screw conveyor handle?

answers:It handles cement, sand, ash, grain, coal powder, chemical fertilizers, and other dry to semi-dry bulk materials.

Q2. What is the temperature limit of the LS screw conveyor?

answers:Material temperature ≤ 200°C; suitable for ambient conditions between –20°C to +50°C.

Q3. How often should maintenance be performed?

answers:Weekly inspections and monthly lubrication ensure optimal performance and minimize downtime.

Q4. Can it be customized for corrosive materials?

answers:Yes, stainless steel or coated versions are available for high-corrosion environments.

Q5. What certification does Senotay’s LS screw conveyor hold?

answers:The product meets CE, ISO 9001:2015, and ATEX standards for quality and safety compliance.