What is a Horizontal Electrostatic Precipitator?

Horizontal Electrostatic Precipitator is a high efficient air pollution control device that used to remove fine particulate matter like dust, fume and smoke from industrial exhaust gases. Unlike conventional filtration systems here the Horizontal ESP utilizes an electrostatic charge to precipitate and collect airborne particles on collection plates.

We Hebei OuTai Environmental Protection Equipment Co., Ltd. a leading Electrostatic Precipitator Manufacturer and ESP Supplier in China specializes in the design and production and installation of Dry Electrostatic Precipitators . Which is used for heavy industries ensuring long service life with superior efficiency and compliance with international environmental standards.

What Makes Horizontal Electrostatic Precipitator the Right Choice?

Choosing a Horizontal Electrostatic Precipitator ensures:

High Efficiency: It have a high effieciency rate that can removes up to 99.9% of dust and smoke particles.

Adaptability: This type of ESP is perfect for high volume gas streams in steel, cement and power industries.

Low Operational Cost: This ESP also requires minimal maintenance and consumes less power compared to wet scrubbers and fabric filters.

Durable Construction: It is Designed for long term operation under extreme temperatures and corrosive environments.

Environmentally Friendly: It is Eco friendly and it Supports zero emission goals and provides cleaner air discharge.

Product Description & Material Properties

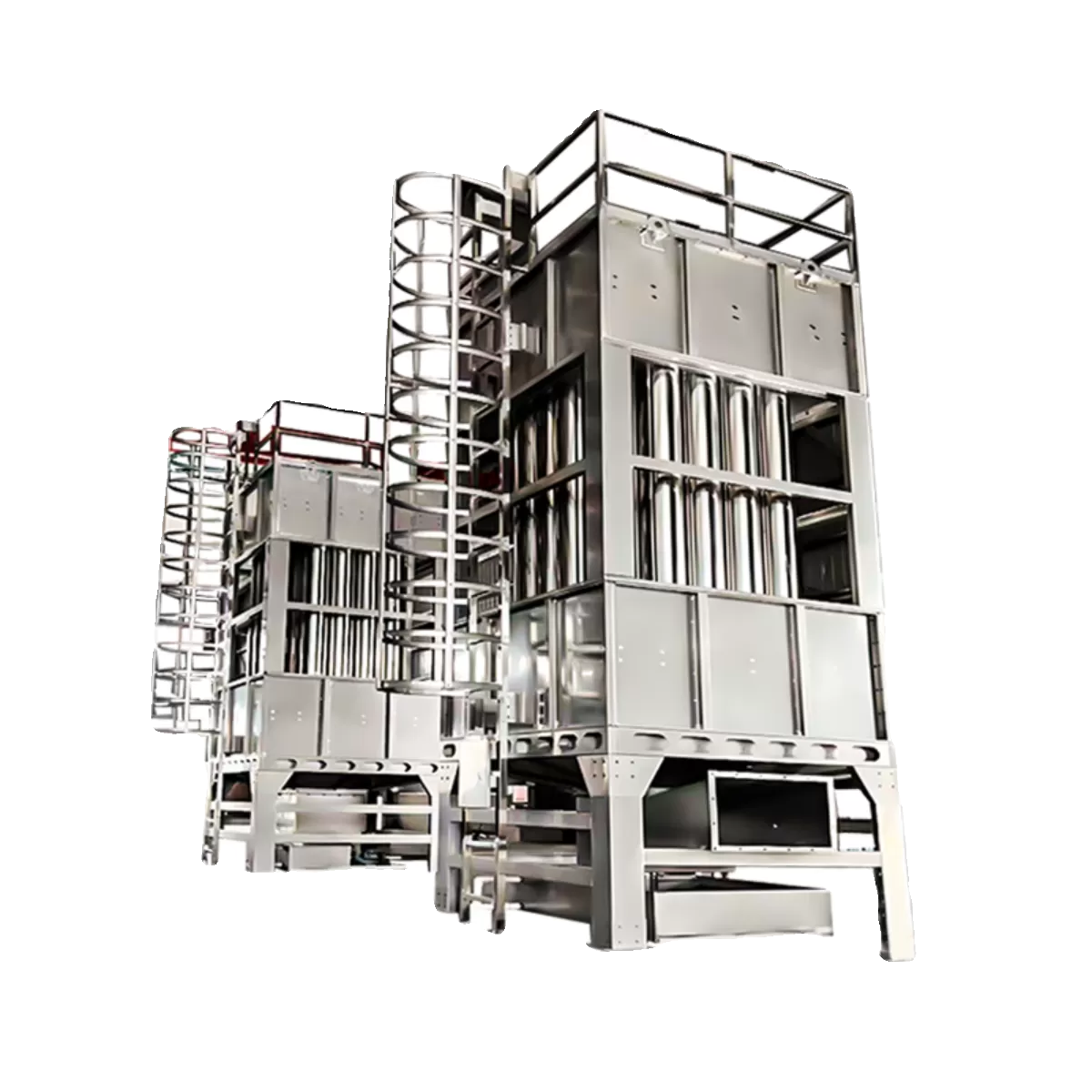

The Horizontal Dry Electrostatic Precipitator consists of high quality discharge electrodes, collecting plates, rapping systems and a gas distribution chamber.And all engineered for maximum performance and durability.

Standard Material Composition:

Casing: The casing is built with Mild steel or stainless steel (customizable design)

Electrode Material: High‑tensile carbon steel / corrosion‑resistant alloy

Insulators: Ceramic or porcelain for superior dielectric strength

Rapper System: Mechanical/hammer/anvil type for dust removal

Transformer‑Rectifier Set: Ensures steady high-voltage DC power supply

Standard Physical & Mechanical Properties:

Temperature Resistance: Up to 450°C (optional up to 650°C)

Voltage Range: 30–110 kV

Collection Surface Area: 50 m² – 20,000 m²

Efficiency: ≥99.7%

Dust Load Capacity: Up to 250 g/Nm³

Horizontal Electrostatic Precipitator — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Overall Length: 6,000–18,000 mm | Gas Flow Rate: 20,000–1,200,000 m³/h | Carbon Steel / Corten Steel | 380–660 V / 50 Hz | Service Life: 20–25 years |

Overall Width: 3,000–8,000 mm | Collection Efficiency: ≥ 99.5% | Rigid Spike / Wire Type | 0.2–0.4 kWh / 1,000 m³ | ISO 9001:2015 |

Overall Height: 4,500–12,000 mm | Particle Size Capture: ≥ 0.5 μm | 6–10 mm | 45–75 kV | CE Certified |

Inlet Flange Size: Φ800–Φ3,500 mm | Dust Concentration Inlet: ≤ 50 g/Nm³ | Q235 / Q345 Steel | 200–1,200 mA | GB / JB Industrial Standards |

Outlet Flange Size: Φ800–Φ3,500 mm | Dust Concentration Outlet: ≤ 30 mg/Nm³ | 95% Alumina Ceramic | ≤ 250°C | GB16297-1996 |

(BCD): Φ760–Φ3,300 mm | Pressure Drop: 150–350 Pa | Electromagnetic / Hammer Type | 450°C (with insulation) | > 10⁸ rapping cycles |

Support Column Spacing: 2,500–4,000 mm | Gas Velocity: 0.6–1.2 m/s | Graphite / High-Temp Fiber | 25–220 tons | 6–12 months |

Hopper Discharge Size: 300×300–600×600 mm | Specific Collection Area (SCA): 80–150 m²/(m³/s) | 50–100 mm | 0.5–30 t/h | ≥ 80,000 hrs |

Types of Horizontal Electrostatic Precipitators

Type No. | Model | Gas Volume (m³/h) | Surface Area (m²) | Efficiency (%) | Operation Temp (°C) | Application |

HESP‑100 | Standard Dry Type | 50,000 | 1,200 | 99.5 | ≤350 | Cement plants |

HESP‑200 | Heavy Duty | 120,000 | 2,500 | 99.7 | ≤400 | Thermal power plants |

HESP‑300 | Multi‑Chamber | 200,000 | 4,000 | 99.8 | ≤450 | Steel mills |

HESP‑400 | Dual Flow | 300,000 | 5,800 | 99.9 | ≤500 | Petrochemical industry |

HESP‑500 | Compact Series | 40,000 | 800 | 98.5 | ≤300 | Biomass plants |

HESP‑600 | High Temp | 150,000 | 2,200 | 99.6 | ≤550 | Non‑ferrous smelting |

HESP‑700 | Low Energy | 90,000 | 1,500 | 99.3 | ≤400 | Paper and pulp |

HESP‑800 | Custom Modular | 220,000 | 3,500 | 99.9 | ≤480 | Glass manufacturing |

HESP‑900 | Large Industrial | 400,000 | 6,800 | 99.9 | ≤520 | Waste incineration |

HESP‑1000 | Ultra Performance | 500,000 | 8,000 | 99.95 | ≤550 | Power-generation plants |

Horizontal Electrostatic Precipitator Working Mechanism

Particle Charging: In particle charging process Dust laden gas enters the ESP horizontally and passes through discharge electrodes where particles are electrically charged.

Particle Collection: Here in this process those charged particles migrate toward the collecting plates due to electrostatic attraction.

Dust Removal: The collected dust is periodically removed by the rapper mechanism, dropping into hoppers.

Clean Gas Discharge: Clean air exits the system through an outlet duct, meeting stringent emission norms.

Core Components of the Horizontal ESP

Component | Description | Material | Function |

Discharge Electrodes | Emit electrical charge | Alloy steel | Particle charging |

Collecting Plates | Collect charged dust | Carbon/stainless steel | Particle collection |

Rapping System | Shakes plates clean | Mechanical / pneumatic | Dust dislodging |

Hoppers | Collect dust | Carbon steel | Dust storage |

TR Set | High-voltage supply | Electric module | Power regulation |

Control Panel | Monitors operation | PLC-based system | Process automation |

Installation Method

Our Senotay’s new addition Horizontal Electrostatic Precipitators are delivered in modular format for easy on site assembly. They can be installed on existing gas ducts or flue systems. Some Installation includes:

Foundation alignment.

Assembly of casing and internals.

Electrical wiring and TR set connection.

Commissioning and performance testing.

Technical Advantages in Manufacturing (Senotay Quality Promise)

Senotay combines precision engineering, robotic welding and electrostatic simulation analysis to ensure consistent emission control efficiency:

Advanced CFD modeling for uniform gas flow distribution.

High-voltage insulation systems for safety and reliability.

Corrosion‑resistant coatings to enhance lifespan.

Digital PLC control system for real-time monitoring.

Customizable modular design for flexible configurations.

FAQs

Q1: What’s the difference between a Horizontal and Vertical Electrostatic Precipitator?

Answer:Horizontal ESPs are suitable for large gas volumes with lower height clearance, while vertical types are ideal for compact space and lower flow rates.

Q2: What is the efficiency of a Horizontal ESP?

Answer:Senotay’s units achieve 99.7–99.95% dust collection efficiency that depending on your application and operation parameters.

Q3: How often does a Horizontal ESP require maintenance?

Answer: Makesure a routine inspection in every 3–6 months ensures optimal operation. Rapping systems and electrodes are designed for long term use.

Q4: Can it handle corrosive or high-temperature gases?

Answer:Yes, Our Senotay’s ESPs are made with corrosion resistant alloys and heat-treated casings, supporting continuous operation up to 650°C.

Q5: Is customization available?

Answer: yes customization is available. We Senotay provides custom engineering based on gas composition, flow rate, space constraint and emission limits.