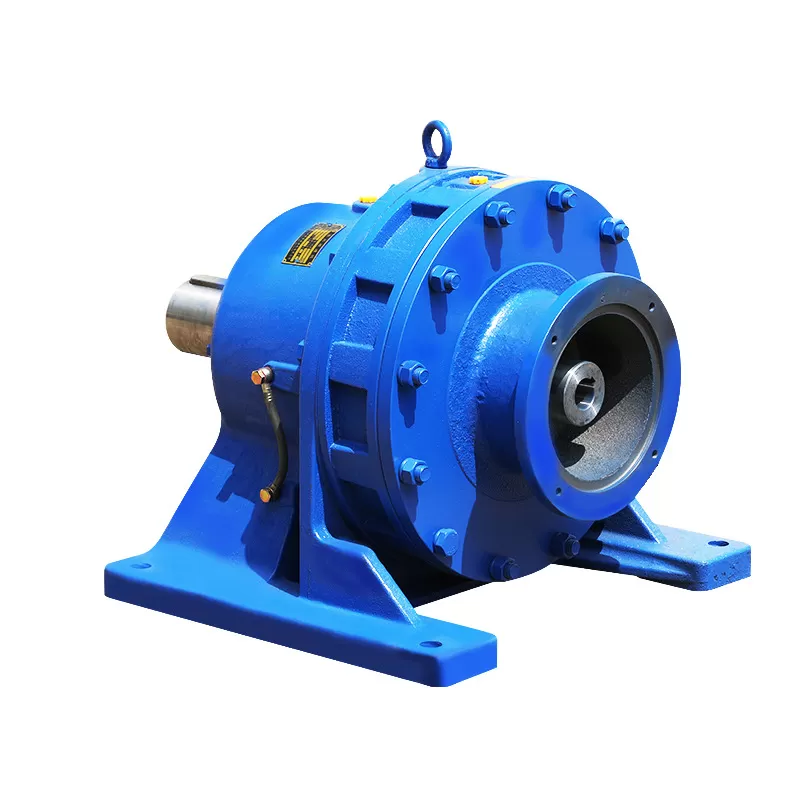

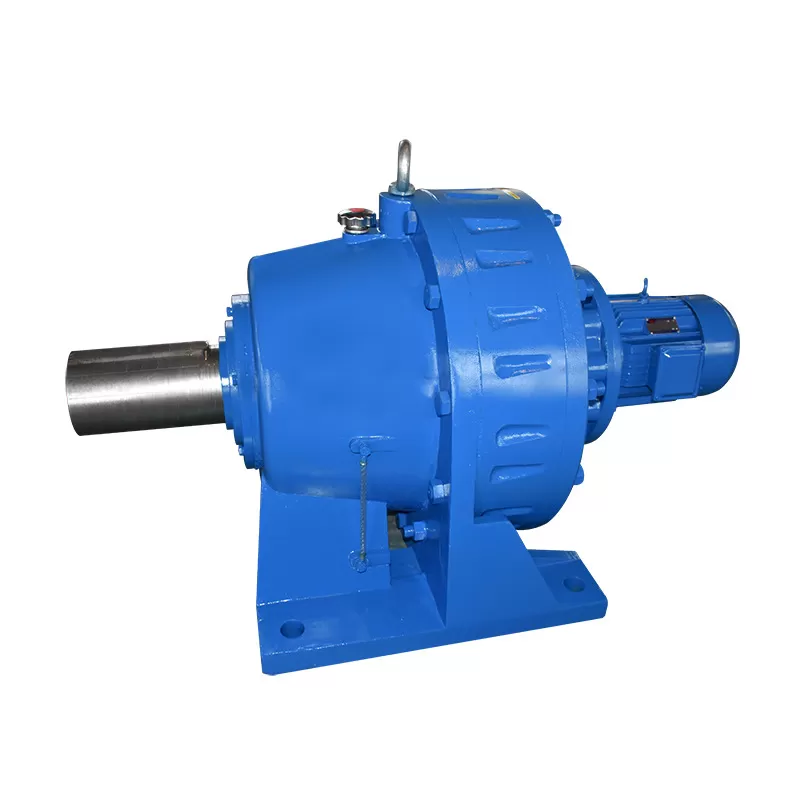

What is a Horizontal Cycloid Reducer?

A Horizontal Cycloid Reducer which is also known as a Cycloidal Speed Reducer or Planetary Cycloidal Reducer.This cycloid reducere is an advanced motion control device engineered to deliver high torque with smooth transmission and precise positioning in compact industrial applications.Its a conventional gearboxes the Cycloid Gear Reducer uses a unique cycloidal motion principle to convert high speed motor input into low speed, high torque output with minimal backlash and noise.

We Hebei OuTai Environmental Protection Equipment Co., Ltd. a trusted chinese manufacturer.Our Horizontal Cycloid Gear Reducers are manufactured with precision balanced cycloidal discs with hardened alloy pinwheels and robust cast iron housings. We use to qualityful materials is to ensure exceptional durability and efficiency and even in the most demanding environments.

Senotay Horizontal Cycloid Reducer why is your best choice?

We selected a Senotay Horizontal Cycloid Reducer for the perfect blend of performance, durability and service life few other drive solutions can match. Here’s why:

1. Superior Torque Transfer Rating: -Up to 50,000+ Nm with a consistently distributed load on multiple contact points.

2. Low backlash & High accuracy: Precise positioning, perfect for automation, robotics and for heavy tooling.

3. Optimal Solution: It have High 85%-94% efficiency reduces power loss and save on electricity.

4. Long Service Life & Low Maintenance: It is specially Designed for >20,000 hours of operating life with low lubrication needs.

5. Various Configurations Available: This sysyem is Foot mounted, flange mounted and solid shaft or hollow output are all available to meet your equipment requirements.

Product Description, Materials & Mechanical Properties

Every Senotay Cycloid Reducer is designed for industrial-grade performance and extended service life. The gearbox integrates premium materials and precision engineering to ensure consistent operation under heavy loads.

Key Component | Material | Mechanical Properties | Standard / Certification |

Housing | GG25 / EN-GJL-250 Cast Iron (optional Aluminum Alloy AlSi10Mg) | Tensile Strength ≥ 250 MPa | EN 10204 3.1 |

Cycloidal Disc | 20CrMnTiA (Case Carburized) | Surface HRC 58-62, Core HRC 30-40 | ISO/TR 14179 |

Pinwheel / Pins | 42CrMo (Hardened Alloy Steel) | High wear and fatigue resistance | AGMA 2000-C88 |

Bearings | GCr15 | Long-life anti-friction design | ISO 281 |

Seals | Double-Lip Oil Seals + Labyrinth | IP65 protection | DIN 3760 |

Lubrication | Synthetic Gear Oil ISO VG 220 or Grease EP2 | High-temperature resistance up to 120°C | DIN 51517 Part 3 |

Types of cycloid reducer

Model Type | Reduction Ratio (i) | Input Power (kW) | Output Torque (Nm) | Efficiency (%) | Mounting Option | Backlash (arcmin) |

HCR-29-011-F1 | 1:11 | 0.12 – 2.2 | 100 – 800 | 94 | Foot | <3 |

HCR-35-017-S1 | 1:17 | 0.37 – 3.0 | 250 – 1200 | 93 | Solid Shaft | <3 |

HCR-43-029-F2 | 1:29 | 0.75 – 5.5 | 500 – 2500 | 92 | Flange | <5 |

HCR-59-035-F1 | 1:35 | 1.1 – 7.5 | 800 – 3200 | 92 | Foot | <5 |

HCR-71-043-S2 | 1:43 | 2.2 – 11 | 1500 – 4500 | 91 | Hollow Shaft | <5 |

HCR-87-059-F2 | 1:59 | 3.0 – 15 | 2000 – 9000 | 91 | Flange | <5 |

HCR-119-071-S1 | 1:71 | 5.5 – 18.5 | 3000 – 12,000 | 90 | Solid Shaft | <5 |

HCR-150-087-F1 | 1:87 | 7.5 – 22 | 4000 – 15,000 | 89 | Foot | <5 |

HCR-200-119-F2 | 1:119 | 11 – 37 | 6000 – 25,000 | 88 | Flange | <5 |

HCR-270-150-S2 | Custom | 18 – 45 | 10,000 – 50,000+ | 85 | Hollow Shaft | <5 |

Horizontal Cycloid Reducer — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Center Height: 80–450 mm | Reduction Ratio: 6:1 – 87:1 | HT250 Cast Iron | Rated Input Speed: 1,500 rpm | Design Service Life: ≥ 20,000 h |

Overall Length: 220–1,150 mm | Rated Output Torque: 180–18,000 Nm | 40Cr, HRC 58–62 | Max Input Speed: 1,800 rpm | ISO 9001:2015 |

Overall Width: 160–720 mm | Peak Torque Capacity: 2.0 × Rated Torque | GCr15 Bearing Steel | Efficiency: 90–93% | GB/T 19001 |

Overall Height: 180–780 mm | Transmission Accuracy: ≤ 1 arc-min | 42CrMo, Heat Treated | ≤ 1 arc-min | CE (Optional) |

Output Shaft Dia.: Φ25–Φ120 mm | Overload Capacity: 200–300% | SKF / NSK / HRB | ≤ 65 dB(A) | RoHS (Optional) |

Input Flange Size: Φ90–Φ300 mm | Torque Density: 30–50 Nm/kg | NBR / Viton | Lubrication Type: Oil Bath | Maintenance Interval: 5,000 h |

(BCD): Φ110–Φ360 mm | Speed Stability: ±0.5% | Grade 10.9 Bolts | Oil Capacity: 0.8–6.5 L | ≥ 1,000,000 |

Mounting Base Size: 140×140–560×560 mm | Temperature Rise: ≤ 35°C | Anti-corrosion Paint | –20 to +80°C | ≥ 30,000 h |

Unit Weight: 18–680 kg | Input Power Range: 0.18–55 kW | ISO 1328 Grade 6 | Horizontal | 12–18 months |

Working Mechanism of Horizontal Cycloid Reducer

The Horizontal Cycloid Reducer functions on the cycloidal motion principle, transforming high-speed rotation into controlled, low-speed, high-torque output:

Input Rotation: The motor drives an eccentric bearing, producing an eccentric motion.

Cycloidal Disc Oscillation: Cycloidal discs oscillate and engage with fixed pins, generating a uniquely efficient rotary motion.

Torque Transmission: This motion is transmitted to the output shaft via rollers or pins, ensuring smooth and continuous torque delivery.

Output Motion: The resulting rotation is steady, precise, and significantly reduced in speed — ideal for automation and heavy-duty machinery.

Characteristics of Senotay Horizontal Cycloid Reducer

High reduction ratio that’s up to 1:119 per stage.

It have Low backlash upto<3 arcmin for precision grade..

Robust cast-iron housing for heavy-duty industrial use.

Compact, space-saving horizontal design.

· Shock-resistant cycloidal disc transmission.

Wide operating temperature range (-20°C to +90°C standard).

Options for natural, fan, or water cooling.

CE, ISO 9001, RoHS 3 and REACH certified.

Core Components & Installation Methods

Core Components:

Cycloidal Disc.

Eccentric Bearing Assembly.

Pinwheel and Rollers.

Output Shaft and Housing.

Dual Oil Seals and Labyrinth System.

Installation Methods:

F1: Foot Mounted.

F2: Flange Mounted.

S1: Solid Shaft.

S2: Hollow Shaft

Mounting holes comply with ISO 273 Medium Fit standards for easy system integration.

Technical Advantages in Senotay Manufacturing

Senotay ensures precise and efficient gearbox performance by combining state-of-the-art CNC machining, advanced heat treatment, and rigorous quality inspection:

In-house carburizing and quenching ensure long service life.

Dynamic balancing of discs reduces noise and vibration.

Strict ISO 9001:2015 quality control and testing per ISO 10816-3 vibration standards.

Custom-made solutions for specific torque, mounting, and environmental demands.

FAQs

Q1: What makes a Horizontal Cycloid Reducer different from a standard gearbox?

Answers: Its cycloidal motion design provides higher torque density, lower backlash, and superior shock resistance compared to conventional gear reducers.

Q2: Can it operate continuously?

Answers: Yes. It’s designed for S1 continuous operation modes in industrial applications.

Q3: What is the typical maintenance schedule?

Answers: Only regular lubrication and inspection are needed — it’s nearly maintenance-free.

Q4: Can it be customized for specific requirements?

Answers: Absolutely. We provide custom shaft designs, special coatings, sensors, and non-standard ratios upon request.

Q5: Is it suitable for high-temperature or outdoor use?

Answers: Yes. Optional high-temperature lubrication and IP65 sealing make it reliable in extreme environments.