What is a Grinding Table Dust Collector?

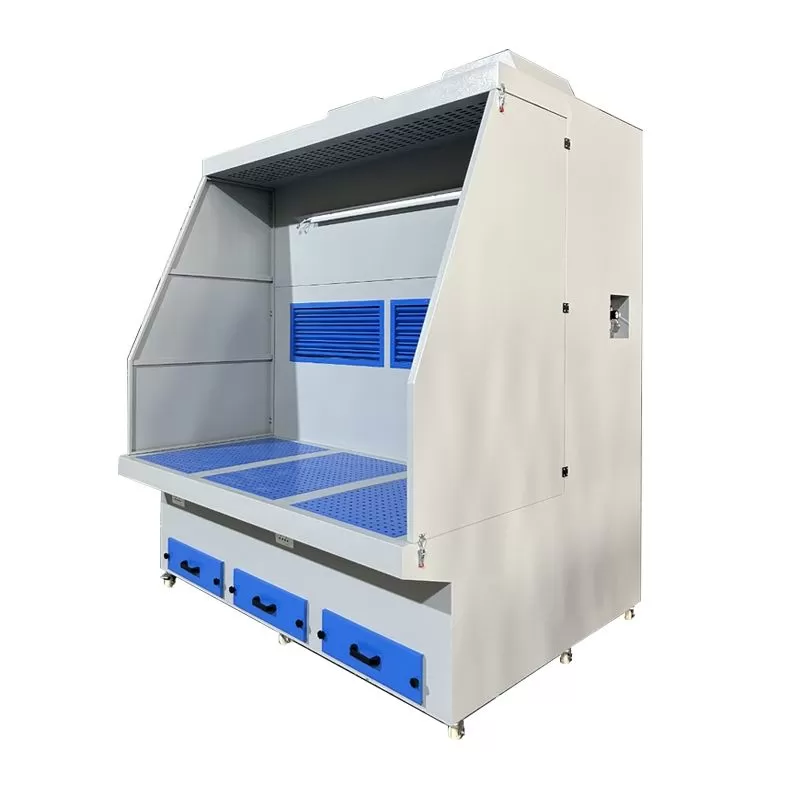

A Grinding Table Dust Collector is an advanced industrial dust extraction system specifically designed for grinding, polishing, deburring, and sanding operations. This metalworking dust collection system integrates a built-in suction table with high-efficiency filtration modules to capture airborne pollutants, grinding dust, and metal particles directly at the source.

Manufactured by Hebei OuTai Environmental Protection Equipment Co., Ltd. Which are a leading grinding dust collector manufacturer in China, the system ensures superior air quality, extended machinery lifespan, and compliance with occupational health and safety standards.

Why Choose a Grinding Table Dust Collector?

Industrial grinding and welding produce fine metallic and abrasive particulates that can harm workers, degrade equipment, and contaminate indoor air. A Grinding Table Dust Collector ensures clean, safe, and regulated work environments by efficiently capturing these emissions.

Key Benefits:

High Dust Collection Efficiency: Removes up to 99.9% of airborne contaminants using multi-stage filtration.

Improves Worker Safety: Keeps respirable dust below permissible exposure levels.

Enhances Productivity: Maintains clear work zones, extending tool life.

Eco-Friendly System: Reduces environmental impact with energy-efficient design.

Customizable: Available in various sizes and air-volume capacities to match your workshop flow.

Types of Grinding Table Dust Collectors

Type No. | Air Volume (m³/h) | Motor Power (kW) | Filter Type | Table Size (mm) | Noise Level (dB) | Special Features |

GTDC-1000 | 2000 | 3 | Cartridge | 1000×800 | ≤70 | Compact design |

GTDC-1500 | 3000 | 4 | HEPA + Carbon | 1500×1000 | ≤72 | Dual suction zones |

GTDC-2000 | 4000 | 5.5 | Cartridge | 2000×1000 | ≤74 | Automatic cleaning |

GTDC-2500 | 5000 | 7.5 | HEPA | 2500×1200 | ≤75 | Explosion-proof version |

GTDC-3000 | 6000 | 7.5 | HEPA + Carbon | 3000×1200 | ≤75 | Multi-operator use |

GTDC-3500 | 7000 | 11 | Cartridge | 3500×1500 | ≤76 | Integrated filters |

GTDC-4000 | 8000 | 11 | HEPA | 4000×1500 | ≤77 | High-temp resistant |

GTDC-4500 | 9000 | 15 | Cartridge | 4500×1500 | ≤78 | IoT smart monitoring |

GTDC-5000 | 10000 | 18.5 | Hybrid | 5000×1800 | ≤80 | Welded frame |

GTDC-6000 | 12000 | 22 | HEPA + Pulse Jet | 6000×2000 | ≤82 | Industrial heavy-duty |

Grinding Table Dust Collector — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Table Length: 800–2,400 mm | Airflow Capacity: 1,200–6,500 m³/h | SS304 / Q235 | 68–82 dB(A) | 10–15 years |

Table Width: 600–1,200 mm | Negative Pressure: −1,200 to −2,800 Pa | Nano-fiber / Polyester | 20–80 °C | 6–12 months |

Table Height: 850–950 mm | Filter Efficiency: 99.0–99.9% (≥ 1 μm) | 1–6 pcs | 90 °C | Up to 500,000 cycles |

Suction Slot Diameter: DN160–DN250 | Dust Load Capacity: 50–180 g/m³ | 2.5–5.0 mm | 4–6 Bar | ISO 9001 / CE |

Footprint Area: 0.9–2.8 m² | Face Velocity: 0.5–1.2 m/s | EPDM / Silicone | 1.1–7.5 kW | OSHA / NIOSH |

Access Door Size: 300×450 mm | Capture Velocity: 20–28 m/s | Powder-coated Steel | 1,400–2,800 rpm | C2–C4 |

Bolt Circle Diameter (BCD): 180–400 mm | Static Pressure: Up to 3,000 Pa | Epoxy / Polyurethane | 150–620 kg | 1,000–2,000 h |

Work Surface Opening Rate: 35–55% | Emission after Filtration: < 5 mg/m³ | Grade 8.8 / SS304 | : 35–90 Nm | > 1,000,000 |

Product Description, Material Properties & Standard Specifications

Senotay’s Grinding Table Dust Collector combines robust structural design with advanced filtration technology. The housing is fabricated from industrial-grade cold-rolled or stainless steel (Q235/SS304) with exceptional resistance to corrosion, vibration, and temperature variation.

Parameter | Specification |

Material | Q235 / Stainless Steel (SS304) |

Filtration Efficiency | ≥ 99.8% with HEPA or cartridge filters |

Air Volume Capacity | 2,000 – 8,000 m³/h |

Noise Level | ≤ 75 dB (A) |

Surface Treatment | Powder-coated / anti-corrosion finish |

Operating Temperature | Up to 400°C |

Standard Certifications | CE, CSA, ISO9001 |

Expected Lifespan | 15+ years (with proper maintenance) |

How Does a Grinding Table Dust Collector Work?

Suction Stage:

Dust-laden air generated from grinding falls onto the perforated table surface. The integrated downdraft system draws contaminated air into the collector housing through evenly distributed suction points.

Filtration Stage:

Inside the chamber, large particulates are separated using cyclone pre-filtration, followed by precision HEPA filters or cartridge filtration elements that trap finer dust below 0.3μm.

Air Purification:

The cleaned air passes through activated carbon or fine mesh screens before being recirculated back to the workshop or exhausted outdoors.

Dust Disposal:

Collected dust drops into a drawer-type dust bin or automatic discharge hopper, simplifying waste management and preventing recontamination.

Features of the Grinding Table Dust Collector

Modular Design: Adaptable workstation design for various workplace layouts.

HEPA Filtration: Captures ultrafine grinding particulates with 99.97% efficiency.

Quiet Operation: Engineered airflow structure ensures minimal noise.

Anti-Spark Safety Features: Optional spark arrestors for high-heat grinding processes.

Energy Saving: Low-power fans with high aerodynamic efficiency.

Low Maintenance: Easy filter cleaning and long service intervals.

Customizable Table Size: Ergonomically designed surface for operator comfort.

Core Components

Grinding Table Surface: Heavy-duty perforated steel with vacuum suction ports.

Centrifugal Fan & Motor: TEFC, Class F motors from 3–10 HP, designed for 24/7 operation.

Filtration System: Cartridge / HEPA / activated carbon filters for multilevel air cleaning.

Collection Bin: Detachable or rotary airlock-guided dust drawers.

Control Panel: Intelligent monitoring of airflow, filter pressure, and maintenance alerts.

Soundproof Housing: Reduces operational noise.

Installation Method

Place the Unit: Position near grinding machines; ensure a level surface.

Duct Connection: Connect flexible or rigid ducts to grinding workstations.

Power Supply Wiring: Use appropriately rated circuit breakers per the motor specifications.

Filter & Fan Testing: Run airflow test and check suction uniformity.

Maintenance Setup: Schedule filter inspection every 2–3 months depending on usage intensity.

Technical Advantages in Senotay Manufacturing

Hebei OuTai Environmental Protection Equipment Co., Ltd. (Senotay) employs advanced CAD/CAM design, laser cutting technology, and robotic welding to manufacture precision-engineered dust collectors.

Each unit undergoes:

Airflow simulation analysis for vortex optimization.

Weld-seam integrity testing.

Dynamic balance testing for fans.

CE and CSA quality audit.

Final performance calibration before packaging.

Senotay’s Grinding Table Dust Collector guarantees durability, efficiency, and compliance with global air quality regulations.

FAQs

1. What sets Senotay apart from other Grinding Table Dust Collector manufacturers?

Answers:Senotay combines over 20 years of engineering expertise, ISO & CE certifications, and custom manufacturing capabilities, ensuring unmatched quality and performance for industrial clients worldwide.

2. Can this collector handle flammable or explosive dust?

Answers:Yes. Models with ATEX-certified components and spark arresters are available for explosive or high-heat environments.

3. How often should the filters be replaced?

Answers:Under typical use, replace filters every 12–18 months, or as indicated by differential pressure gauges.

4. Is customization available?

Answers:Absolutely. We design customized Grinding Table Dust Collectors tailored to your space, material type, and airflow requirements.

5. What after-sales support is provided?

Answers:Senotay offers installation guidance, lifetime technical support, and global after-sales services to ensure long-term reliability.