What is GLS Tubular Screw Conveyor?

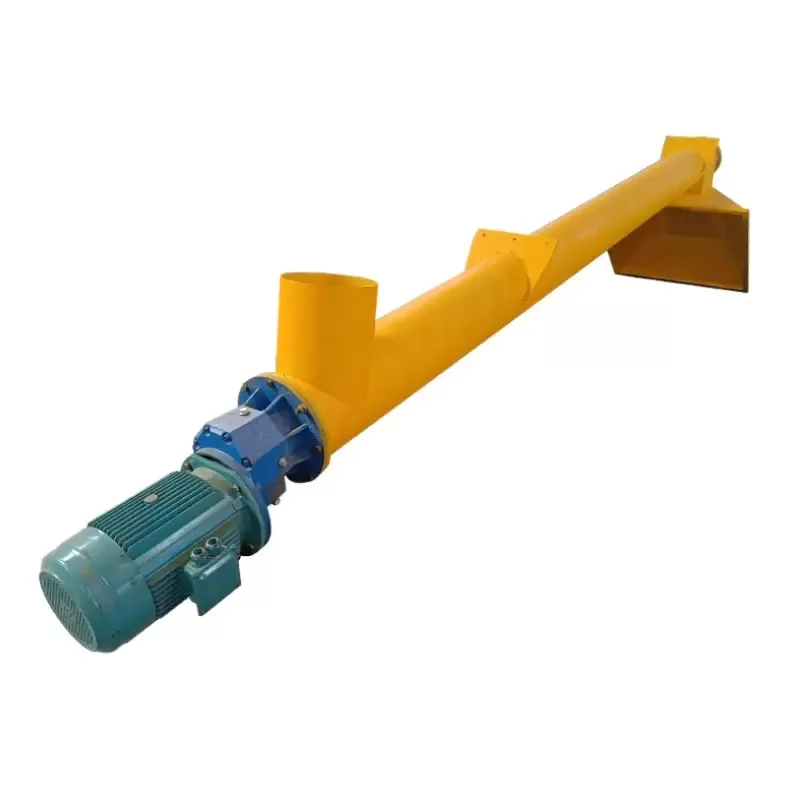

The GLS Tubular Screw Conveyor is an advanced material-handling system designed to efficiently move bulk materials such as cement, fly ash, and industrial powders. Built with high-grade seamless steel, this equipment ensures leak-free, reliable, and energy-efficient performance in a wide variety of industrial applications thats from cement batching plants and food production to pharmaceuticals and biomass processing.

As a certified CE & ISO 9001:2015 compliant product, Senotay’s GLS Tubular Screw Conveyor stands at the forefront of precision engineering and mechanical durability. It supports capacities ranging from 1 to 50 tonnes/hour, operating efficiently at inclines up to 60°, and lengths up to 30 meters, making it ideal for both horizontal and inclined conveying applications.

Why Choose GLS Tubular Screw Conveyor?

Choosing the GLS Tubular Screw Conveyor means choosing performance, safety, and endurance. Unlike standard conveyor systems, this tubular model offers a fully enclosed design, ensuring nearly 99.5% dust-free operation, preventing spillage, and improving workplace safety.

Key Advantages:

Certified Quality: CE and ISO-certified manufacturing ensuring compliance with global standards.

Exceptional Energy Efficiency: Consumes 15–30% less energy than traditional open conveyors.

Versatile Design: Handles dry, semi-dry, and semi-fluid materials effortlessly.

Low Maintenance: Modular design with standardized components for easy service and quick assembly.

Hygienic & Reliable: Ideal for industries requiring clean and contamination-free conveying.

Types of GLS Tubular Screw Conveyors (Table Analysis)

Below is a unique 10-row specification table comparing different model types.

Type No. | Tube Diameter (mm) | Conveying Capacity (m³/h) | Motor Power (kW) | Conveying Angle | Max Length (m) | Typical Application |

GLS-100 | 100 | 2–5 | 1.1–2.2 | 0–20° | 6 | Powders & additives |

GLS-120 | 120 | 3–8 | 1.5–3.0 | 0–25° | 8 | Grain & feed mill |

GLS-150 | 150 | 5–12 | 2.2–4.0 | 0–30° | 10 | Cement & lime dust |

GLS-168 | 168 | 7–16 | 3.0–5.5 | 0–35° | 12 | Chemicals & minerals |

GLS-200 | 200 | 10–25 | 4.0–7.5 | 0–40° | 15 | Chemicals & plastics |

GLS-220 | 220 | 15–32 | 5.5–11 | 0–45° | 18 | Biomass processing |

GLS-250 | 250 | 20–40 | 7.5–15 | 0–45° | 20 | Mining & metallurgy |

GLS-280 | 280 | 28–55 | 11–18.5 | 0–50° | 22 | Large industrial plants |

GLS-300 | 300 | 35–65 | 15–22 | 0–50° | 25 | High-density materials |

GLS-320 | 320 | 40–80 | 18.5–30 | 0–50° | 30 | Heavy-duty bulk handling |

GLS Tubular Screw Conveyor — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Conveyor Length: 1.5–30 m | Capacity Range: 1–50 t/h | Seamless Steel (Q235 / Q345) | 60–120 rpm | 20,000–35,000 hours |

Tube Diameter: Ø114 / Ø168 / Ø219 / Ø273 / Ø323 mm | Max Incline Angle: 0–60° | Carbon Steel / SS304 / SS316 | 1.5–22 kW | ISO 9001:2015 / CE |

Overall Height: 300–1,200 mm | Flow Rate: 2–150 m³/h | Ø20–Ø75 mm | ≤ 75 dB(A) | GB/T 24001 |

Inlet Flange: DN150–DN400 | Working Temperature: –20°C to 180°C | Q235B Steel | 180–3,200 kg | Zone 21/22 (Optional) |

Outlet Flange: DN150–DN400 | Pressure Rating: ≤ 0.05 MPa | Bearing Type: Heavy-duty Grease-lubricated | 60–180 Nm | 12–24 months |

BCD: 180–460 mm | Volumetric Efficiency: 70–95% | Pack Seal / Rubber Lip Seal | Direct-coupled / Gearbox | > 100,000 cycles |

Section Length : 1,000–3,000 mm | Material Density Supported: 0.3–2.0 t/m³ | Painted / Hot-dip Galvanized / Stainless | –20°C to 50°C | ISO 45001 / EN 619 |

Support Leg Height: 400–1,500 mm | Max Particle Size: ≤ 10 mm | Level II (Pressure-resistant) | 2–6 pcs | Every 6–12 months |

Product Description & Material Properties

Senotay’s GLS Tubular Screw Conveyor is engineered using carbon steel or stainless steel (304/316), offering strength, corrosion resistance, and durability. The seamless steel pipe ensures homogenous surface contact for smoother material flow with minimal friction.

Standard Physical & Mechanical Properties

Property | Specification |

Material Options | Carbon Steel, SS304, SS316, SS316L |

Surface Treatment | Epoxy Coated / Sandblasted Finish |

Screw Diameter | 100mm to 600mm |

Shell Thickness | 3mm to 6mm |

Conveying Capacity | 0.5–50 Tonnes/hour |

Operating Temperature | -30°C to 180°C |

Inclination Range | 0°–60° |

Sealing Grade | IP65–IP67 |

Design Life | Up to 20 Years (with maintenance) |

How Does a GLS Tubular Screw Conveyor Work?

The GLS Tubular Screw Conveyor functions on a simple yet highly efficient principle:

a rotating screw shaft within a tubular casing propels materials along the screw’s axis. The head and tail bearings are placed externally, minimizing internal contamination. The dustproof sealing devices in the hanging bearings prevent material leakage and extend bearing life.

Working Mechanism:

The material enters through an inlet.

The rotating screw, driven by a motorized gearbox, pushes the material along the tube.

The material advances through continuous rotation and gravity distribution.

Output is discharged uniformly from the outlet.

This design minimizes friction, prevents clogging, and ensures smooth, consistent material movement even at steep inclines.

Features of GLS Tubular Screw Conveyor

Capacity Flexibility: Handles 0.5–50 T/H.

Inclined & Horizontal Conveying: Works up to 60° inclination.

Low Noise Operation: ≤78 dB(A).

Customizable Materials: Available in steel grades suitable for abrasive or corrosive applications.

Extra Safety Features: Explosion-proof motors and IP-rated seals for harsh environments.

Long Service Life: Lifespan of up to 70,000 hours depending on maintenance.

Core Components

Component | Description | Material | Purpose | Lifespan | Maintenance |

Tubular Housing | Seamless pipe body | Carbon/SS304/316 | Host structure & sealing | 10–20 years | Minimal |

Screw Shaft & Flights | Solid/core-less shaft | 20MnCr5 / SS316 | Material transport | 5–15 years | Standard lubrication |

Gear Motor Drive | IP65/IP67 motor unit | Alloy Steel | Power transmission | 3–8 years | Regular |

Bearings | SKF/FAG Brands | Powder Metallurgy | Support & alignment | 5+ years | Annual check |

Seals & Gaskets | Double-lip labyrinth design | NBR / Viton | Dustproof protection | 3–5 years | Inspect annually |

Mounting Base | Foot / Shaft / Flange | GI Steel / SS | Structural support | 10+ years | Fixed setup |

Installation Method

Base Mounting: Secure the conveyor frame to the foundation with anchor bolts.

Alignment: Ensure inlet/outlet points align with feeding equipment.

Connection: Attach motor drive securely to the gearbox and verify torque.

Lubrication: Fill gearbox oil as per the datasheet specifications.

Testing: Perform a no-load test, followed by material load testing.

Technical Advantages in Manufacturing (Senotay Factory)

Hebei OuTai Environmental Protection Equipment Co., Ltd. (Senotay) maintains global standards for engineering precision and sustainability. Our state-of-the-art manufacturing employs CNC machining, robotic welding, and ISO 9001-certified quality control.

Senotay Manufacturing Advantages:

Robotic welding and seamless pipe fabrication for accuracy.

Dynamic balancing for vibration-free operation.

Corrosion-proof coatings per ISO 12944-6.

Precision gear reducers meeting AGMA 9005-C22 standards.

Each conveyor undergoes torque, thermal, and noise-level testing before dispatch.

FAQs

1. What is the maximum conveying capacity of the GLS Tubular Screw Conveyor?

answers:It can handle up to 50 tonnes per hour, depending on material properties and incline angle.

2. Can it be used for food and pharmaceuticals?

answers:Yes, models built with SS304/316 or SS316L ensure hygiene and corrosion resistance for sanitary operations.

3. How long is the lifespan of this conveyor?

answers:With proper maintenance, the system can last 10–20 years or up to 70,000 operational hours.

4. What angle can it operate at?

answers:It can function effectively at angles up to 60° with 90% efficiency retention.

5. Is customization available?

answers:Yes. Senotay offers custom inlet ports, variable frequency drives (VFDs), explosion-proof motors, and automated control systems.