What is an FU Chain Conveyor?

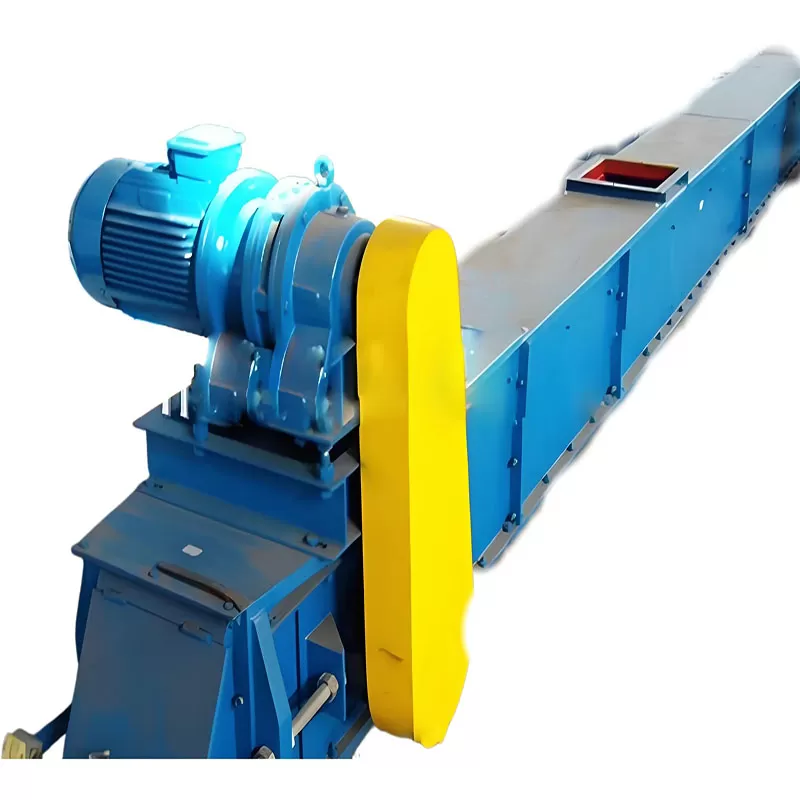

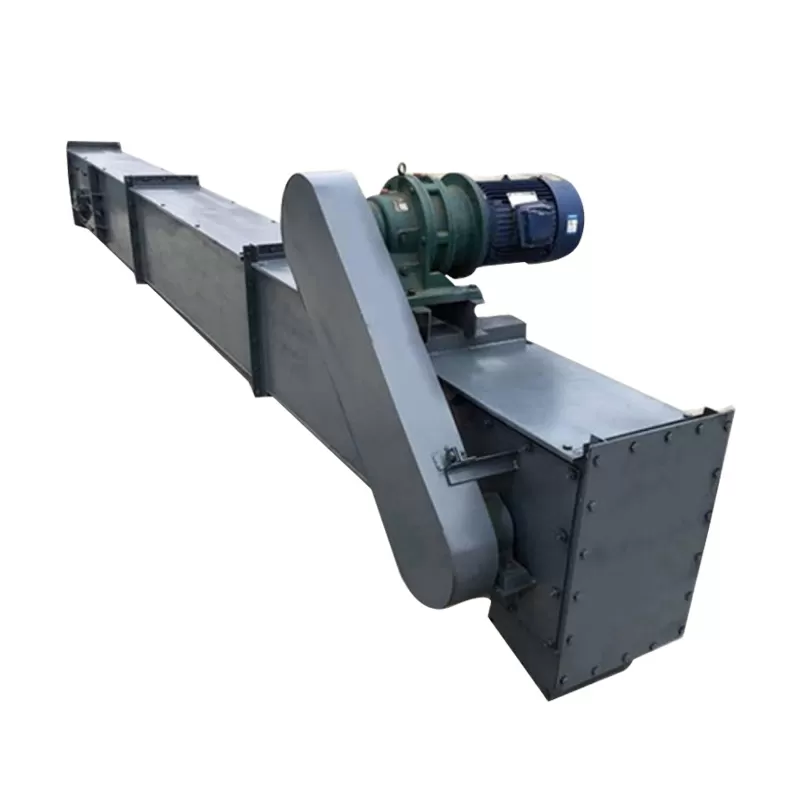

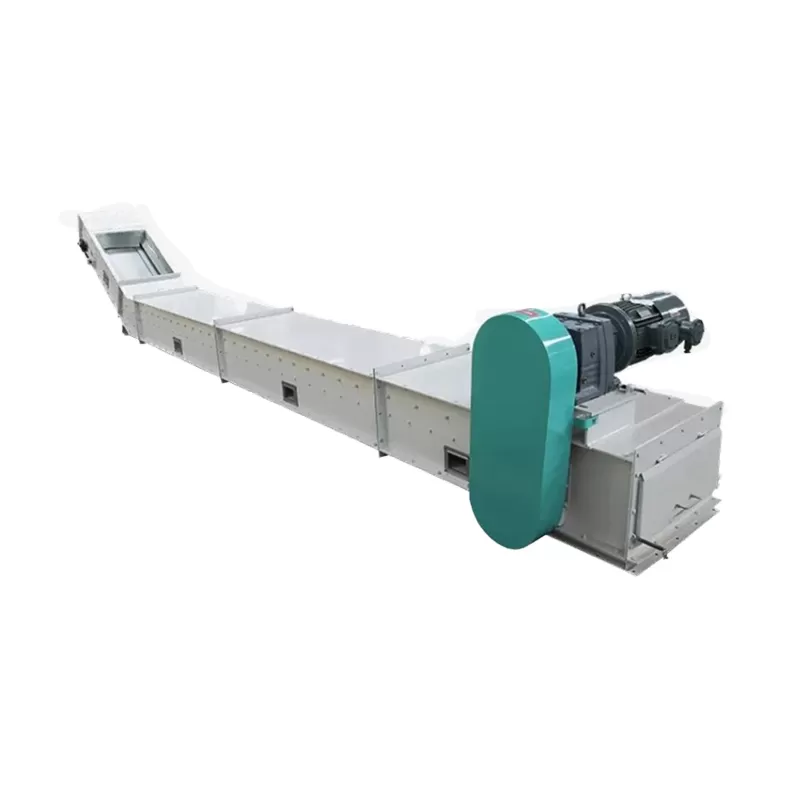

An FU chain conveyor which is also known as an FU type drag chain conveyor or en masse conveyor . This chain conyeyor is also a high efficiency material handling system engineered for the horizontal or inclined transport up to 15° of bulk materials such as powders, granules and small particles. The system operates on the en masse conveying principle where the material is moved as a continuous and solid mass within a fully enclosed casing by means of a precision engineered chain fitted with conveying flights.

The FU chain conveyor is generally used for cement, grain, coal, fly ash, chemical, minerals and similar materials that require dust free conveying, stable flow and long service life. Here in Hebei OuTai Environmental Protection Equipment Co., Ltd. Our FU chain conveyors deliver exceptional reliability including energy efficiency and dust free operation that making them ideal for industries such as cement, construction, thermal power, chemicals, food processing, machinery and mining.

What makes FU Chain Conveyor a best choice

Industries select FU type chain conveyors because they deliver high conveying efficiency, stable material flow, and minimal residue, all within a fully enclosed structure that prevents leakage and environmental contamination.

Key reasons include:

High Capacity & Low Energy Use –For high capacity here the En masse conveying improves efficiency by up to 40%.

Dust Tight Operation – This chain conveyor is Ideal for powders and hazardous materials.

Long Service Life – For a long term service wear resistant chains and liners extend operational lifespan.

Space Saving Design – This chain conveyor have compact structure and flexible layout options.

Stable Conveying for Bulk Solids – Here its stable conveying system is specially effective for uniform, free-flowing materials.

FU Chain Conveyor Types Table (10 Types)

Below is a unique, detailed table analyzing 10 FU conveyor types with key specifications.

Type Model | Trough Width (mm) | Capacity (m³/h) | Chain Speed (m/s) | Max Conveying Distance (m) | Bulk Density Range (t/m³) | Drive Power (kW) |

FU150 | 150 | 10–20 | 0.16–0.25 | 20 | 0.2–1.2 | 1.5–3 |

FU200 | 200 | 20–35 | 0.16–0.25 | 25 | 0.3–1.4 | 2.2–4 |

FU270 | 270 | 35–55 | 0.16–0.32 | 30 | 0.3–1.6 | 3–5.5 |

FU350 | 350 | 50–90 | 0.16–0.32 | 35 | 0.4–1.8 | 4–7.5 |

FU410 | 410 | 70–110 | 0.16–0.32 | 40 | 0.4–1.8 | 5.5–11 |

FU500 | 500 | 100–180 | 0.16–0.32 | 50 | 0.5–1.8 | 7.5–15 |

FU600 | 600 | 130–240 | 0.16–0.32 | 55 | 0.5–1.8 | 11–18.5 |

FU700 | 700 | 180–300 | 0.16–0.32 | 60 | 0.5–1.8 | 15–22 |

FU800 | 800 | 220–350 | 0.16–0.32 | 60 | 0.5–1.8 | 18.5–30 |

FU900 | 900 | 260–420 | 0.16–0.32 | 60 | 0.5–1.8 | 22–37 |

FU Chain Conveyor – Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Conveyor Length: 3,000–60,000 mm | Operating Pressure: 0.2–0.8 Bar | Q235 / Q345 Carbon Steel | 180–450 Nm | 8–15 years |

Trough Width: 160–500 mm | Max Pressure: 1.0 Bar | 20Mn2 / 40Cr / 20CrMnTi | 250–3,000 kg | 20,000–36,000 hrs |

Trough Height: 180–650 mm | Operating Temp: –20 to 90 °C | CS / Polymer / Mn Steel | 0.10–0.60 m/s | 10–16 months |

Inlet Size: 200–600 mm | Max Temp: 120 °C | UHMW-PE / NM400 | 2.2–30 kW | ISO 9001:2015 / CE |

Outlet Size: 250–650 mm | Capacity: 12–220 m³/h | 100–200 mm | 0–15° | JB/T 3926 |

Flange Size: Ø220–Ø780 mm | Conveying Efficiency: 90–96 % | 3–6 mm | ≤ 2.8 mm/s | EN 619 |

BCD: Ø180–Ø760 mm | Max Particle Size: ≤ 20 mm | Labyrinth / Rubber | 2–4 reinforced pads | 1,200–1,800 hrs |

Product Description & Material Properties

Senotay’s FU chain conveyor series (FU150–FU600) integrates precision-engineered alloy steel, heavy-duty casings, and modular design for optimal durability and maintenance ease.

Material Construction & Physical Properties:

Component | Material | Hardness / Strength | Standard | Properties |

Conveyor Chain | Alloy Steel (20CrMnTi) | HRC 58±3 | DIN 3990 | Heat-treated for wear resistance |

Housing / Trough | Carbon Steel (Q235/SS400) | 4.5–8mm thick | ASTM A36 / GB-T700 | Welded, corrosion-resistant |

Bearings | High-precision Sealed Bearings | ISO ABEC Class 5 | ISO 1328-1 | Long-life and self-lubricated |

Shaft | Solid / Hollow Steel Shaft | ±0.05mm Runout | DIN 748-1 | Rigid, vibration-resistant |

Sealing System | Double-lip Oil Seal | IP65 | IEC 60529 | Dust-tight & moisture-proof |

How Does an FU Chain Conveyor Work? (Working Mechanism)

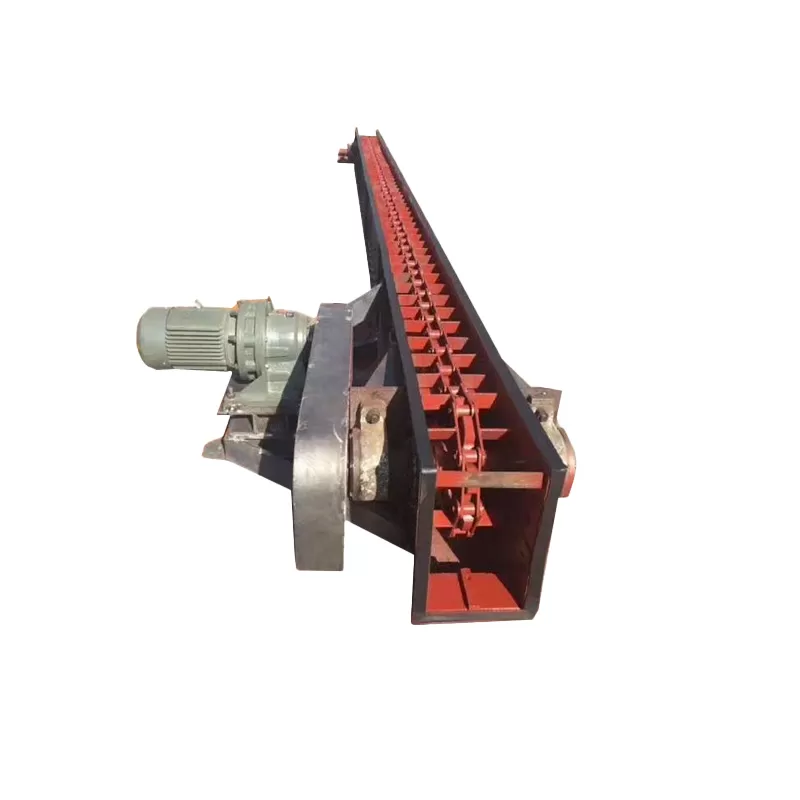

The FU chain conveyor operates on the principle of en-masse conveying:

A high-strength alloy chain moves inside a sealed rectangular trough.

Scraper plates attached to the chain push material forward.

Bulk materials form a moving column (the "en-masse" effect).

Friction between particles allows the entire material bed to flow uniformly.

Material discharges steadily at the outlet.

This simple, robust mechanism ensures:

Who Uses an FU Chain Conveyor?

The FU-type chain conveyor is essential in industries including:

Cement plants

Chemical industry

Mining & minerals processing

Power plants (fly ash & coal handling)

Grain & feed mills

Environmental protection systems

Metallurgy & smelting facilities

Wherever bulk powders or granules must be conveyed cleanly and efficiently, FU chain conveyors are the preferred solution.

Key Features of the FU Chain Conveyor

Fully sealed and dust-proof structure

Wear-resistant chains and scrapers for longer lifespan

Smooth and stable conveying with minimal power consumption

Suitable for horizontal or low-incline (< 20°) installations

Low noise and reduced mechanical vibration

Easy maintenance with removable trough covers

Modular design for simple extension or layout modification

Core Components

A complete FU chain conveyor system includes:

Hardened alloy conveyor chain

Scraper blades / flights

Enclosed steel trough (U or rectangular)

Drive head & motor gearbox

Tail section with tensioning device

Liners (UHMW-PE, manganese steel, or ceramic)

Inspection hatches & outlet ports

Each component is engineered for long service life and reliable bulk material transport.

Installation Method

FU chain conveyors can be installed:

Horizontally

With slight inclines (0°–20°)

On floor supports or overhead brackets

With direct coupling or chain drive motor setups

Common installation steps:

Fix the head and tail sections.

Install trough sections sequentially.

Connect and tension the chain.

Install scraper blades.

Mount motor and check alignment.

Test run and adjust speed/tension.

Senotay provides on-site installation guidance or remote technical support.

Technical Advantages in Manufacturing (Senotay Engineering Strength)

Senotay leverages advanced production systems to build high-quality FU chain conveyors:

Laser-cut steel plates for precision and tight sealing

Heat-treated alloy chains offering high tensile strength

CNC-machined sprockets for smooth, quiet operation

Anti-wear liners extending trough life up to 3×

CE & ISO 9001:2015 certified manufacturing

Customizable conveyors for capacity, temperature, and material type

Our engineering ensures durability, high performance, and superior reliability in industrial applications.

FAQs

1. What materials can an FU chain conveyor transport?

Answers: Powders, granules, and small bulk solids including cement, fly ash, grains, minerals, coal, chemicals, and pellets.

2. Is the FU chain conveyor dust-proof?

Answers: Yes. It features a fully enclosed design to prevent material leakage and reduce environmental pollution.

3. What is the maximum conveying distance?

Answers: Up to 60 meters per conveyor unit; multiple units can be combined.

4. What are the maintenance requirements?

Answers: Only periodic chain tensioning, lubrication of bearings, and inspection of liners—maintenance is minimal.

5. Can the conveyor be customized?

Answers: Yes. Senotay offers customized sizes, materials, temperature-resistant designs, and drive configurations.

6. Does Senotay manufacture FU chain conveyors?

Yes. Senotay (Hebei OuTai Environmental Protection Equipment Co., Ltd.) is a professional FU chain conveyor manufacturer with global exports.