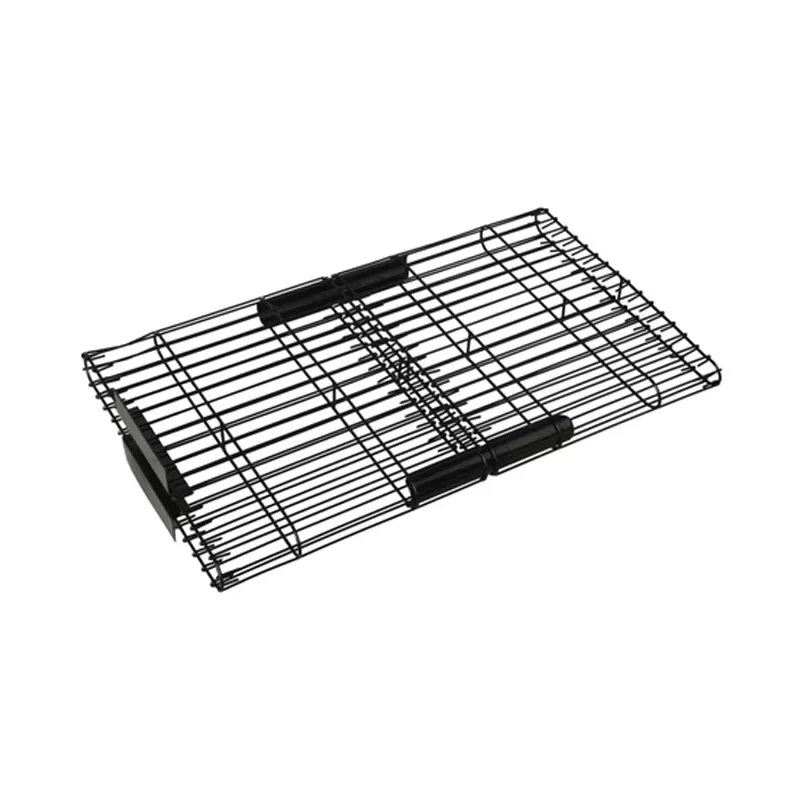

What is an Envelope Bag Cage? Why is it called an Envelope?

An Envelope Bag Cage is a specialized structural frame designed to support envelope-shaped filter bags used in industrial dust collectors and baghouses. Unlike cylindrical or trapezoidal cages, the envelope design features flat and rectangular sides, which optimize airflow distribution and minimize dead zones within the dust collector chamber.

This shape helps ensure uniform dust dislodgement during pulse-jet cleaning, prevents bag collapse, and improves the overall filtration area-to-space ratio. Envelope bag cages are ideal for compact dust collection units, especially where installation space is limited but high filtration efficiency is essential.

Material Properties of Envelope Bag Cage

Property | Detail |

Base Materials | Carbon steel, mild steel, stainless steel (304 / 316L), or customized alloys |

Surface Treatments | Galvanized, epoxy-coated, silicone-coated, or powder-coated |

Temperature Resistance | Up to 350°C (depending on coating type) |

Corrosion Resistance | Excellent performance under humid, acidic, or alkaline gases |

Welding Type | Automatic spot welding for strength and precision |

Customization | Various lengths, widths, and wire thicknesses available |

These materials provide exceptional strength, corrosion resistance, and dimensional stability under harsh industrial conditions.

Main Features of Envelope Bag Cage

This Compact rectangular (envelope) structural design for effective space usage.

It is Optimized airflow passage to minimize dust adhesion and pressure drop.

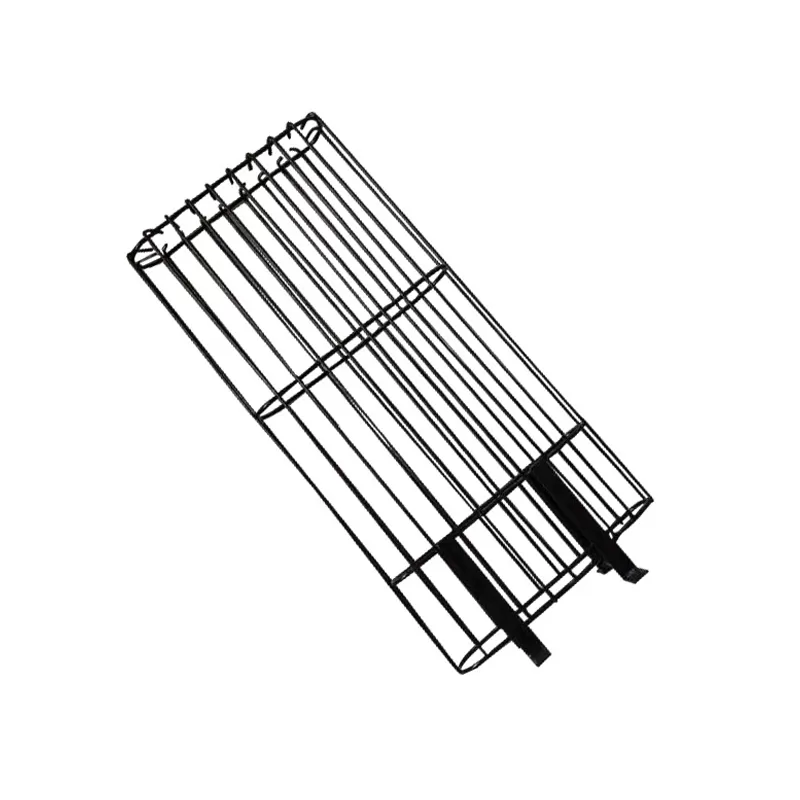

It Enhanced mechanical strength and stability for pulse-jet or reverse-clean systems.

The Smooth welding joints ensure minimal filter bag wear and long bag life.

Custom venturi, frame and connection options compatible with different dust collector models.

Supports both pulse-jet cleaning and shaking-type dust collectors.

Types of Envelope Bag Cage

Type No. | Material | Surface Coating | Connection Type | Operating Temp (°C) |

EBC-01 | Carbon steel | Hot-dip galvanized | Flange | 250 |

EBC-02 | Stainless steel 304 | Natural finish | Thread | 350 |

EBC-03 | Alloy steel | Silicone coated | Snap ring | 300 |

EBC-04 | Mild steel | Powder-coated | Clamp | 280 |

EBC-05 | Galvanized steel | Zinc plating | Venturi connection | 300 |

EBC-06 | Stainless steel 316 | Anti-acid coating | Quick release | 360 |

EBC-07 | Reinforced steel | Dual layer coating | Flange lock | 330 |

EBC-08 | Electro-galvanized | Bright finish | Collar joint | 260 |

EBC-09 | Carbon steel hybrid | Hybrid coat | Welded type | 320 |

EBC-10 | Custom alloy | Custom finish | Designed type | 350 |

Why Envelope Bag Cage is Unique Compared to Other Bag Cages

The Envelope Bag Cage stands out due to its flat, space-efficient geometry. which improves dust releasing capability and maximizes filter bag area. The envelope shape allows closer cage arrangements without the airflow loss ideal for installations with compact dust collector layouts.

Additionally, due to reduced friction points and less mechanical wear, these cages significantly extend filter bag service life. Their robustness and low-maintenance operation make them a durable, cost-effective, and energy-efficient alternative to round or trapezoidal cages.

Physical and Mechanical Properties of Envelope Bag Cage

Property | Specification |

Tensile Strength | ≥ 340 MPa |

Wire Diameter | 2.8–5.0 mm |

Weld Integrity | 100% fusion checked |

Thermal Resistance | Up to 350°C |

Corrosion Resistance Test | ≥ 500 hours (salt spray) |

Dimensional Tolerance | ±1 mm |

Hardness | 60–75 HRB |

Specifications Table for Envelope Bag Cage

Length (mm) | Width (mm) | Thickness (mm) | Frame Type | Coating Option |

1000 | 120 | 25 | Flat frame | Galvanized |

1500 | 140 | 30 | Reinforced frame | Epoxy powder |

2000 | 160 | 35 | Venturi type | Silicone coated |

2500 | 180 | 40 | Rigid frame | Hot-dip zinc |

3000 | 200 | 45 | Welded frame | Fluorocarbon coat |

3500 | 220 | 50 | Bolted frame | Powder-coated |

4000 | 240 | 55 | Modular frame | Bright finish |

4500 | 260 | 60 | Custom joint frame | Anti-rust zinc |

5000 | 280 | 65 | Multi-section frame | Hybrid coated |

Custom | Custom | Custom | Custom design | Custom coating |

Why It’s Important to Have an Envelope Bag Cage in Your Dust Industry

Enhanced Filtration Efficiency – better air dispersion reduces dust load and pressure loss.

Extended Filter Longevity – less bag-to-cage wear and consistent support during pulsing.

Optimized Space Utilization – perfect for compact or modular dust collection systems.

Reduced Maintenance Costs – corrosion-resistant finish increases lifespan.

Improved Operating Stability – stable support framework prevents filter deformation.

Advantages of Envelope Bag Cage

Easy installation and replacement process.

Highly customizable design to fit varied collector models.

Excellent resistance to high temperatures and corrosive gases.

Improved dust cleaning efficiency during reverse-pulse operations.

Lightweight yet high-strength structure.

Sustainable solution with long operational life.

Applications of Envelope Bag Cage

Envelope filter bag cages are essential in dust collection and air purification systems across numerous industries, including:

Cement and asphalt production

Steel and metal foundries

Power plants and energy facilities

Chemical and petrochemical production

Food and pharmaceutical operations

Mining and quarrying sectors

Woodworking and furniture manufacturing

Waste recycling and incineration plants

Industries Using Envelope Bag Cage

Cement Industry – for kiln and cement mill dust collection.

Chemical & Petrochemical – for capturing fine powders and vapors.

Power Generation – ensures clean emissions from boilers.

Food Processing – meet hygiene and emission standards.

Metal Processing – collect metallic dust from grinding and cutting operations.

Why Choose Hebei OuTai Environmental Protection Equipment Co., Ltd

Hebei OuTai (Senotay) stands as a trusted manufacturer and global supplier of industrial dust filter bags.

Our Competitive Edge:

We have Over 15 years experience in environmental air filtration systems.

State-of-the-art facility with international QC complianc.

We can have Custom-made designs to fit all major baghouse systems.

Quality certification: We are ISO 9001:2015 certified.

Global Service Reach – We have Fast response, installation guidance and export logistics

Senotay’s commitment to quality ensures that every Acrylic filter bag performs efficiently in the world’s toughest environments.To save the environment is our main goal.

FAQs About Envelope Bag Cage

Q1: What makes envelope bag cages better than round cages?

A: The envelope shape improves airflow uniformity, maximizes filtration area, and allows compact system design.

Q2: Can Outai produce custom envelope bag cages?

A: Yes. We specialize in fully customized cages based on your dust collector size, filter bag type, and operational conditions.

Q3: What materials are used in manufacturing?

A: Carbon steel, galvanized steel, and stainless steel 304/316 with multiple coating options.

Q4: Are they suitable for high-temperature operations?

A: Yes. Our coated cages withstand continuous temperatures up to 350°C.

Q5: How long does an envelope bag cage last?

A: Under proper maintenance, these cages can last 8–10 years or longer.