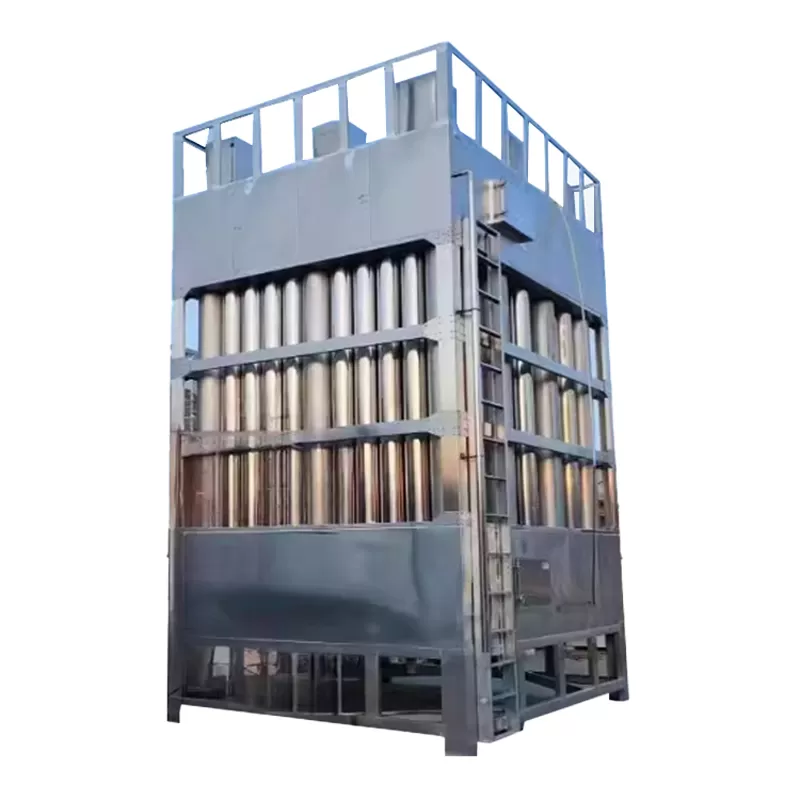

What Is an Electrostatic Dust Collector?

An Electrostatic Dust Collector (ESP) that also known as an Electrostatic Precipitator, is a highly efficient air filtration system designed to remove fine dust particles, smoke, fumes, and other airborne contaminants from industrial exhaust gases. By leveraging high-voltage electrostatic fields, ESPs effectively separate particulate matter from gas streams also achieving collection efficiencies exceeding 99.9% for particles as small as 1 μm.

Hebei Outai Environmental Protection Equipment Co., Ltd.) we are one of the leading Electrostatic Dust Collector manufacturers in China, delivering CE- and ISO-certified systems designed for power plants, steel plants, chemical industries, and cement manufacturing applications.

Why Choose an Electrostatic Dust Collector?

Industrial operations generate microscopic dust and pollutants that are harmful to both the environment and human health. Conventional filtration systems often struggle to capture ultra-fine particles or require frequent maintenance. The Electrostatic Dust Collector (ESP) solves these challenges by:

Ensuring <10 mg/Nm³outlet dust concentration — meeting global emission norms.

Offering low-pressure drop operation, resulting in decreased energy consumption.

Providing continuous performance without filter clogging or replacement.

Supporting automatic cleaning through mechanical rapping or water washing systems.

Reducing overall maintenance and lifecycle costs, ideal for 24/7 industrial operations.

With Senotay’s ESP Dust Collectors, industries achieve cleaner emissions, better workplace environments, and regulatory compliance with EU and ISO 9001:2015 standards.

Types of Electrostatic Dust Collectors — Comparison Table

Type No. | Model | Airflow Capacity (m³/h) | Power Input (kW) | Efficiency (% @ 0.3µm) | Operating Temp. Range (°C) | Protection Class |

1 | EDC-5000 | 5,000 | 5.5 | 99.5 | -10 ~ 250 | IP54 |

2 | EDC-12000 | 12,000 | 11 | 99.7 | -15 ~ 300 | IP55 |

3 | EDC-30000 | 30,000 | 30 | 99.9 | -20 ~ 390 | IP55 |

4 | EDC-60000 | 60,000 | 55 | 99.9 | -20 ~ 400 | IP56 |

5 | EDC-80000 | 80,000 | 75 | 99.95 | -25 ~ 450 | IP56 |

6 | WEDC-5000 (Wet Type) | 5,000 | 8 | 99.9 | -10 ~ 200 | IP65 |

7 | WEDC-12000 | 12,000 | 12 | 99.97 | -15 ~ 260 | IP65 |

8 | EX-EDC-15000 (Explosion-Proof) | 15,000 | 15 | 99.8 | -20 ~ 300 | ATEX |

9 | HEDC-25000 (High-Temp Version) | 25,000 | 25 | 99.7 | -30 ~ 450 | IP56 |

10 | RX-EDC-50000 (RFID Monitored) | 50,000 | 40 | 99.99 | -20 ~ 390 | IP67 |

Electrostatic Dust Collector — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Length: 2,000–12,000 mm | Filtration Efficiency: ≥ 99.7–99.9% | SS 304 / CS Q235B | 48–75 kV DC | > 80,000 h |

Width: 1,500–8,500 mm | Particle Size Capture: ≥ 1 μm | SS 316 / High-tensile alloy | ≤ 1.5 sparks/min | 15–25 years |

Height: 2,500–10,500 mm | Pressure Rating: –1.5 to –6 kPa | 6–14 mm (CS/SS) | 10,000–450,000 m³/h | ISO 9001 / CE / IEC |

Flue Gas Inlet: DN400–DN2400 | Max Temperature: 150–250°C | Ceramic/Porcelain | 80–220°C | EPA / EN 12741 |

Flue Gas Outlet: DN350–DN2200 | Voltage Ripple: ≤ 5% | Electromagnetic / Mechanical | 150–380 Pa | ≤ 20 mg/m³ |

Access Doors: 500×700 / 600×900 mm | Corona Power: 20–180 kW | 3–8 mm CS/SS | 6–45 kWh | IEC 60060-1 |

BCD (Bolt Circle Dia): 450–2,100 mm | Collection Area: 25–2,800 m² | EPDM / Silicone | 3,500–65,000 kg | Hot-dip galvanized / Epoxy coated |

Base Plate Area: 900–5,200 mm | Migration Velocity: 7–15 cm/s | Carbon Steel + Anti-corrosion coating | Every 4–6 months | Rapper cycle 5–30 min |

Product Description, Material Properties, and Standards

Our Electrostatic Dust Collectors are engineered for reliability, corrosion resistance, and long-term durability. Every component is made from certified structural materials and tested against international industrial standards.

Component | Material / Specification | Properties & Benefits | Standard |

Power Supply | 20–100 kV DC Transformer | Spark suppression, energy-optimized solid-state control | IEC 60204-1 |

Discharge Electrodes | Tungsten / Stainless Steel | High durability, constant corona discharge | ASTM A366 |

Collection Plates | Carbon Steel / Stainless Steel (6–8 m tall) | Corrosion-resistant, optimized spacing | ASTM A240 |

Housing | 4–6 mm Steel with anti-corrosion coating | Structural stability & insulation | ISO 13705 |

Hopper System | Rotary Valves or Screw Conveyors | Automated dust discharge | ASME B16.5 |

Sealing & Protection | IP54–IP55 rated | Weatherproof & explosion-proof | IEC 60529 |

How Does an Electrostatic Dust Collector Work?

The working mechanism of an ESP Dust Collector involves four main stages:

Particle Charging:

Dust-laden gas passes through discharge electrodes, which emit a high-voltage DC field (up to 100 kV). Particles get negatively charged.

Collection:

These charged particles are attracted to positively charged collection plates, where they accumulate.

Dust Removal:

Collected dust is periodically removed using mechanical rapping (dry ESP) or water flushing (wet ESP), dropping into the hopper below.

Clean Air Discharge:

The purified air exits with ultra-low particulate content (<10 mg/Nm³), ensuring clean exhaust according to global environmental standards.

Key Features of Senotay Electrostatic Dust Collector

Ultra-High Filtration Efficiency: 99.9% particle removal rate

Durable, Corrosion-Resistant Materials (Carbon Steel, SS304/316)

Fully Automated Operation and Cleaning

CE, ISO 9001/14001, and ATEX Certified

Customizable Airflow Capacities (5,000–30,000 m³/h)

Energy-efficient transformers and low-pressure operation

Explosion-proof and weatherproof construction options

Core Components

Discharge Electrodes — Create the ionizing corona field.

Collection Plates — Capture charged particles.

Transformer/Rectifier Unit — Provides high-voltage power.

Rapping Mechanism / Water Spray System — Automated cleaning.

Hopper & Dust Conveyor — Smooth dust discharge.

Control Cabinet — Intelligent power regulation and performance monitoring.

Technical Advantages in Manufacturing — Senotay Expertise

Senotay leverages precision engineering and advanced production technologies to produce high-voltage Electrostatic Precipitators with superior efficiency and lifespan. Each ESP is manufactured in compliance with ISO 9001:2015 and undergoes performance testing based on EN ISO 16890, AMCA 210, and ASME B16.5 standards.

Our advanced manufacturing advantages include:

Computerized electrode alignment systems for stable corona formation.

CNC-fabricated plates ensuring low resistance and consistent particle capture.

PLC-controlled power supplies with arc suppression logic.

Efficient insulation and anti-corrosion surface treatments.

Modular designs for simplified transportation and installation.

Installation Method

Foundation Preparation: Level and concrete base alignment.

Module Assembly: Fit collection and discharge plates.

Electrical Setup: High-voltage transformer connection.

Control System Integration: Link power supply to PLC controls.

Commissioning & Testing: Verify voltage, flow rate, and spark suppression.

Senotay offers turnkey installation, commissioning, and operator training for all ESP projects.

FAQs

Q1: What is the lifespan of an Electrostatic Dust Collector?

Answers: Typical lifespan ranges between 15–25 years, depending on maintenance and operational environment.

Q2: Does the ESP require special maintenance?

Answers: Minimal. Routine inspection, voltage monitoring, and periodic plate cleaning ensure optimum performance.

Q3: Can it handle oily or sticky dust?

Answers: Yes, Wet ESP models are designed specifically for high-resistivity and sticky particulate removal.

Q4: What certifications do Senotay products hold?

Answers: CE, ISO 9001/14001, RoHS, and ATEX certifications ensure global quality compliance.

Q5: Is customization available for different industries?

Answers: Yes, Senotay offers custom-designed ESPs tailored to unique airflow, temperature, and emission requirements.