What Is a Combined Cyclone Dust Collector?

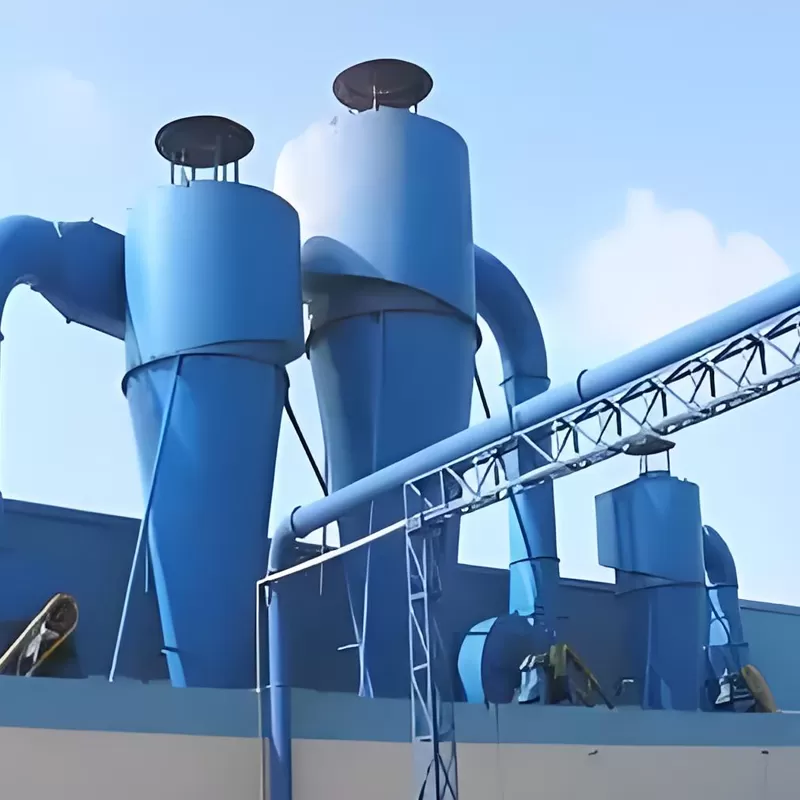

A Combined Cyclone Dust Collector which also called a Multi-Cyclone Dust Collector or Hybrid Dust Collector, is a high-performance air purification and particle separation system designed to efficiently capture industrial dust, debris and fine particulate matter.

This Cyclone Dust Extraction System integrates multiple cyclone separators within a single compact unit, providing exceptional dust separation efficiency and minimal maintenance requirements. It is widely used in heavy-duty industries such as metalworking, woodworking, cement manufacturing, power generation, and chemical processing.

Hebei Outai Environmental Protection Equipment Co., Ltd. manufactures these Industrial Dust Collectors under strict ISO 9001 and CE certifications, ensuring reliability, adherence to global environmental standards, and superior long-term performance.

Why Choose a Combined Cyclone Dust Collector?

Superior Air Purification Efficiency:

With over 99.8% efficiency for particles ≥5 μm, the system minimizes downstream filter load, extending the life of secondary filters.

Energy-Saving Operation:

The multi-cyclone configuration optimizes airflow paths and pressure distribution, reducing energy consumption without compromising performance.

Durability & Continuous Operation:

Built from galvanized steel, powder-coated steel, or stainless steel 304, the collectors are corrosion-resistant and engineered for 15+ years of service life.

Low Maintenance Requirements:

Fewer moving parts and easy-access hoppers make operation and maintenance cost-effective and time-saving.

Compliance & Certification:

CE, ISO 9001, and RoHS certifications guarantee compliance with OSHA, NIOSH, and EU environmental standards.

Types of Combined Cyclone Dust Collectors (Comparative Table)

Model | Airflow (m³/h) | Power (kW) | Efficiency (@0.3 µm) | Material | Noise Level [dB(A)] | Protection Class |

CC-1000 | 1,000 | 3.7 | 99.5% | Galvanized Steel | 70–85 | IP54 |

CC-1500 | 1,500 | 5.5 | 99.6% | Powder-Coated Steel | 72–86 | IP54 |

CC-2000 | 2,000 | 7.5 | 99.7% | Powder-Coated Steel | 75–90 | IP55 |

CC-2500 | 2,500 | 9.0 | 99.7% | Stainless Steel 304 | 76–88 | IP55 |

CC-3000 | 3,000 | 11 | 99.9% | Stainless Steel 304 | 80–95 | IP55 |

CC-4000 | 4,000 | 15 | 99.9% | SS304 / Hybrid Coating | 82–96 | IP55 |

CC-5000 | 5,000 | 18.5 | 99.95% | SS304 | 83–97 | IP55 |

CC-6000 | 6,000 | 22 | 99.95% | SS316 | 85–98 | IP55 |

CC-7000 | 7,000 | 30 | 99.97% | SS316 | 85–99 | IP55 |

CC-8000 | 8,000 | 37 | 99.98% | SS316 / Hybrid Alloy | 86–99 | IP66 |

Combined Cyclone Dust Collector — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Length: 1,200–6,800 mm | Pressure Rating: –3 to –7 kPa | Q235 / SS304 / SS316 | –3.5 to –6 kPa | > 50,000 h |

Width: 1,000–4,200 mm | Max Temperature (standard): 80°C | Carbon Steel / SS | ≤ 150°C | 10–15 years |

Height: 2,800–12,500 mm | Separation Efficiency: 85–95% (particles ≥ 5 μm) | 4–10 mm | 5,000–180,000 m³/h | ISO 9001 / CE |

Inlet Diameter: 300–1,200 mm | Pressure Drop: 800–1,600 Pa | Epoxy / Hot-Dip Galv. | 4–40 units | ≤ 30 mg/m³ |

Outlet Diameter: 250–1,000 mm | Dust Removal Efficiency (with pre-filter): ≥ 98% | NBR / Silicone | 0–95% RH | ≥120 μm |

Flange Size: DN300–DN1200 | Particle Size Range: ≥ 3–10 μm | Q235 Steel | 900–14,000 kg | EPA / EN 12779 |

(BCD): 400–1,150 mm | Max Dust Loading: ≤ 80 g/m³ | EPDM / PTFE | Rotary Valve / Airlock | ATEX Zone 21/22 (optional) |

Access Door: 450×650 mm | Flow Imbalance Tolerance: ≤ 5% | 200–400 mm | 40–160 Nm | Every 6–12 months |

Product Description & Material Properties

The Senotay Combined Cyclone Dust Collector features robust construction and precision-engineered airflow dynamics. The housing materials and filtration media are carefully selected to ensure optimal performance under industrial conditions.

Parameter | Material/Specification | Standard |

Housing Material | Galvanized Steel (2.5 mm), Powder-Coated Steel (3 mm), Stainless Steel 304 (3 mm) | ASTM A653/A240 |

Filter Media | PTFE-Coated Polyester, Fire-Retardant Polyester, Nano-Fiber Composite | NFPA 701, EN 779:2012 |

Sealing Type | IP54/IP55 with Silicone or Double Lip Seals | IEC 60529 |

Airflow Range | 1,000–3,000 m³/h | AMCA 210 |

Operating Temperature | -20°C to 90°C | UL 507 |

Efficiency | 99.5–99.9% @ 0.3 µm | EN ISO 16890 |

Noise Level | 70–95 dB(A) | ISO 3744 |

Vibration | ≤3 mm/s RMS | ISO 10816-3 |

Service Life:

15–20 years of continuous operation with minimal servicing required.

How Does a Combined Cyclone Dust Collector Work?

The working mechanism of the Combined Cyclone Dust Collector is based on centrifugal separation and multi-stage filtration:

Step 1: Dust-Laden Air Entry

Contaminated air enters through a tangential inlet, forming a high-speed spiral (cyclonic flow) distributing it evenly into multiple cyclone chambers.

Step 2: Centrifugal Particle Separation

The centrifugal force pushes heavier particles toward the outer wall, where they lose velocity and fall into the collection hopper.

Step 3: Fine Dust Collection

Finer particles are filtered through additional cyclonic stages, achieving micro-level dust removal.

Step 4: Clean Air Discharge

Purified air exits through a central exhaust manifold, and the separated dust is discharged automatically via a rotary valve.

Core Components

Cyclone separation chambers.

Common air inlet manifold.

Dust collection hopper.

Rotary airlock valve.

Clean air exhaust outlet.

Electrical control panel (CE/ATEX compliant).

Support frame & vibration damping mounts.

Installation Method

Secure the base frame to a concrete foundation.

Connect inlet ducts to the contaminated air source.

Ensure proper sealing around joints and flanges.

Connect the clean air outlet to the exhaust ducting system.

Power up the blower and rotary valve assembly.

Calibrate air velocity and pressure according to operational requirements.

Technical Advantages in Manufacturing (Senotay)

At Hebei Outai Environmental Protection Equipment Co., Ltd., Senotay ensures every Cyclone Filter System embodies:

CNC precision fabrication for consistent cyclone geometry.

ISO-quality inspected welds and anti-corrosive coatings.

Balanced impeller design ensuring minimal vibration.

Advanced flow modeling (CFD) for optimized particle separation.

RFID-based filter monitoring systems (optional).

These factors collectively deliver unmatched efficiency, reliability, and longevity.

FAQs – Combined Cyclone Dust Collector

1. What is the efficiency of a Combined Cyclone Dust Collector?

answers: Over 99.8% removal efficiency for particles ≥5 µm.

2. Can it handle explosive or hazardous dust?

answers: Yes, ATEX-certified explosion-proof models are available for combustible dust environments.

3. What industries commonly use it?

answers: Cement, metal, chemical, wood, textile, and recycling industries.

4. How often does it require maintenance?

answers: Typically once per quarter, with daily hopper emptying and annual inspection.

5. What are the power requirements?

answers: Models range between 3.7 kW to 37 kW, depending on airflow capacity.

6. Is customization available?

answers: Yes – inlet diameters, motor types, body materials, and discharge systems can be tailored to project requirements.