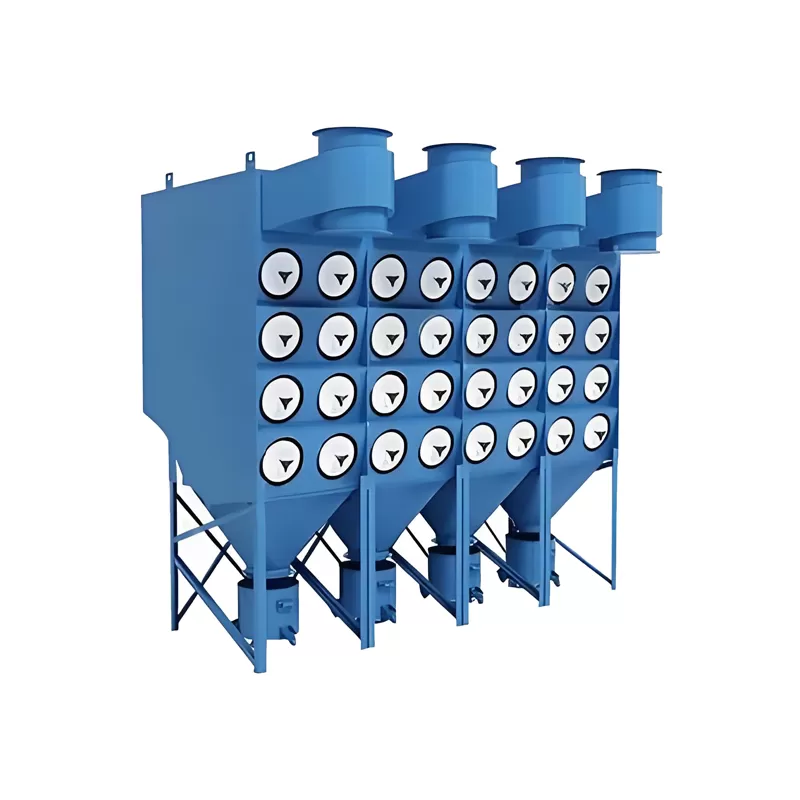

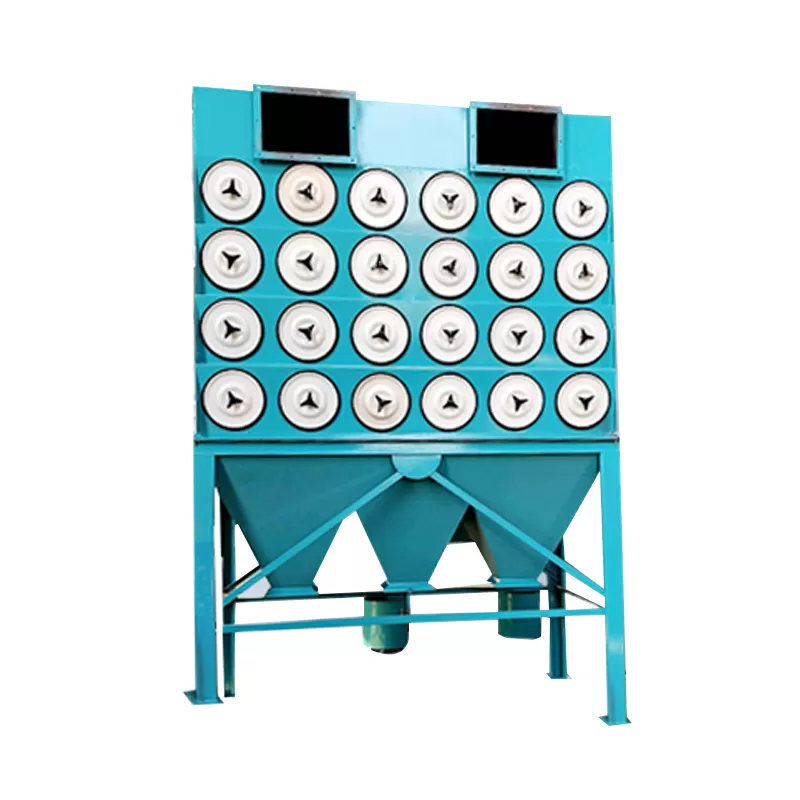

What Is a Cartridge Dust Collector?

A cartridge dust collector is a compact and highly efficient industrial dust collection system designed to capture fine dust, smoke, and particulate matter directly at their source. Compared to traditional baghouse collectors, the cartridge collector uses pleated filter cartridges with an exceptionally large surface area and resulting in superior filtration efficiency with minimal footprint.

At Hebei OuTai Environmental Protection Equipment Co., Ltd.) we are a professional cartridge dust collector manufacturer we offers ISO 9001 and CE-certified systems engineered for long-term performance and compliance with OSHA, NIOSH, and international emission standards.

Why Cartridge Dust Collector?

The Cartridge dust collector is ideal for modern industries requiring flexible and localized dust filtration. It captures particles as small as 0.3 microns with 99.9% filtration efficiency that making it one of the most trusted solutions for precise air filtration.

Unlike bulky centralized dust systems, Senotay’s compact design offers mobility, modularity, and the advantage of point-source extraction which is perfect for welding, grinding, polishing, or chemical processing operations.

Advantages include:

Compact structure with high filter area-to-volume ratio.

Easy maintenance and filter replacement.

Cost-effective operation due to reusable cartridges.

Reduced downtime and energy consumption.

Types of Cartridge Dust Collector Models & Technical Data

Model | Cartridges (pcs) | Power (kW) | Air Volume (m³/h) | Cleaning Method | Efficiency (%) | Dimensions (mm) |

CDC-2 | 2 | 2.2 | 2200 | Pulse Jet | 99.5 | 600×800×1800 |

CDC-4 | 4 | 3.0 | 3000 | Pulse Jet | 99.7 | 800×800×2000 |

CDC-6 | 6 | 5.5 | 6000 | Pulse Jet | 99.8 | 1200×1000×2200 |

CDC-9 | 9 | 7.5 | 7000 | Pulse Jet | 99.9 | 1200×1500×2300 |

CDC-24 | 24 | 3.0 | 3000 | Pulse Jet | 99.9 | 1220×880×4000 |

CDC-48 | 48 | 5.5 | 5000 | Pulse Jet | 99.9 | 1560×1290×4000 |

CDC-100 | 100 | 11 | 10,000 | Pulse Jet | 99.9 | 1900×1900×4500 |

CDC-150 | 150 | 15 | 15,000 | Pulse Jet | 99.9 | 2300×2100×4700 |

CDC-200 | 200 | 18.5 | 20,000 | Pulse Jet | 99.9 | 2600×2300×4800 |

CDC-250 | 250 | 22 | 25,000 | Pulse Jet | 99.9 | 2900×2500×4900 |

Cartridge Dust Collector — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Length: 1,000–4,800 mm | Filter Efficiency: ≥ 99.7% @ 0.3 μm | Cellulose / Polyester / PTFE | 1,500–120,000 m³/h | 12–36 months |

Width: 800–3,200 mm | Pressure Rating: −5 to +3 kPa | 325–355 mm | 0.45–0.65 MPa | 10–20 years |

Height: 1,800–9,500 mm | Operating Temperature: 60–120 °C | 600–1,200 mm | 0.2–0.9 m³/min | ISO 9001 / CE / OSHA / NIOSH |

Inlet Flange Size: DN200–DN1200 | Max Temp (Special Media): 150–180 °C | Q235 / SS304 | 3–160 kW | ≤ 10–20 mg/m³ |

Outlet Flange Size: DN200–DN1000 | Initial Resistance: 110–160 Pa | 3–8 mm | 2–128 cartridges | ≥ 1,000,000 pulses |

(BCD): 150–1,100 mm | Final Resistance: 1,200–1,500 Pa | Silicone / EPDM | 68–82 dB(A) | Industrial Grade A |

Unit Weight: 450–18,000 kg | Air-to-Cloth Ratio: 0.8–1.3 m/min | Epoxy / Polyurethane Coating | 50–150 Nm | C3–C5 |

Access Door Size: 400×600 mm | Leakage Rate: ≤ 0.5% | Carbon Steel | 4–16 holes | 2,000–3,500 h |

Product Description, Material Properties & Standard Mechanical Properties

The Senotay Cartridge Dust Collector is a versatile and durable system, crafted using galvanized, powder-coated, or stainless steel for maximum corrosion resistance and durability. Its unique pleated cartridge filters provide optimized airflow and filtration performance.

Property | Specification |

Housing Material | Galvanized / Powder-coated Steel / Stainless Steel 304 |

Filter Media | Polyester Spunbonded, PTFE-coated, Fire-retardant Options |

Filtration Efficiency | 99.9% @ 0.3 μm |

Cleaning System | Pulse Jet Cleaning System |

Operating Pressure | 400–1500 Pa |

Air Volume Handling | 2200–10,000 m³/h |

Operating Temperature Range | -10°C to 200°C |

Noise Level | 70–90 dB(A) |

Standards | ISO 9001, CE, EN 779, ASME, ATEX Certified |

Why Choose a Cartridge Dust Collector?

Superior Efficiency: 99.9% filtration efficiency for ultra-fine dust and fumes.

Space-Saving Design: Compact and mobile—ideal for limited workspace environments.

Minimal Maintenance: Automatic cleaning prevents clogging.

Energy Efficiency: Reduced fan power requirements due to large filter surface.

Long Service Life: Durable components and high-quality materials for continuous operation.

Core Components

Filter Cartridges:

Pulse Jet Cleaning System:

Housing/Cabinet:

Dust Hopper:

Fan & Motor:

Control System:

Installation Method

Place on a stable, level foundation.

Connect inlet duct to dust source (e.g., grinding booth or welding station).

Connect high-pressure air and electrical lines for pulse system and motor.

Ensure the hopper is linked to a dust discharge valve or container.

Start system and calibrate control settings.

Technical Advantages in Manufacturing at Senotay

Precision Engineering: CNC manufacturing for tight tolerances.

Material Quality: ASTM- and EN-certified metals ensure robustness.

Enhanced Cleaning Performance: Proprietary pulse jet mechanism extends filter life by over 30%.

Custom Design: Single-unit or modular options tailored to application needs.

Global Standards Compliance: CE, ISO 9001:2015, RoHS, and ATEX certifications.

Senotay’s industrial dust collection systems are backed by 20+ years of industry expertise—providing robust, environmentally sustainable solutions trusted across more than 40 countries.

FAQs

Q1: What is the filtration efficiency of the cartridge dust collector?

Answers: It captures 99.9% of dust particles as small as 0.3 microns, ensuring cleaner, breathable air.

Q2: How often should filters be replaced?

Answers: With proper pulse jet cleaning, filter life exceeds 20,000–30,000 hours.

Q3: Is it suitable for flammable dust?

Answers: Yes, explosion-proof variants are available that comply with ATEX directives.

Q4: Can the system be customized?

Answers: Yes, Senotay offers custom air volume, cartridge quantity, and housing materials.

Q5: Does it meet international standards?

Answers: Yes, certified for ISO 9001:2015, CE, and RoHS compliance.