What is an Activated Carbon Adsorption Box?

An Activated Carbon Adsorption Box is an industrial air purification system that removes gaseous pollutants and odors using the principle of adsorption. The activated carbon within the box captures VOCs, organic fumes and other chemical vapors by trapping molecules onto its highly porous surface.

These systems are essential in industries where gaseous pollutants or odors are generated, such as paint lines, chemical plants and waste gas treatment facilities.

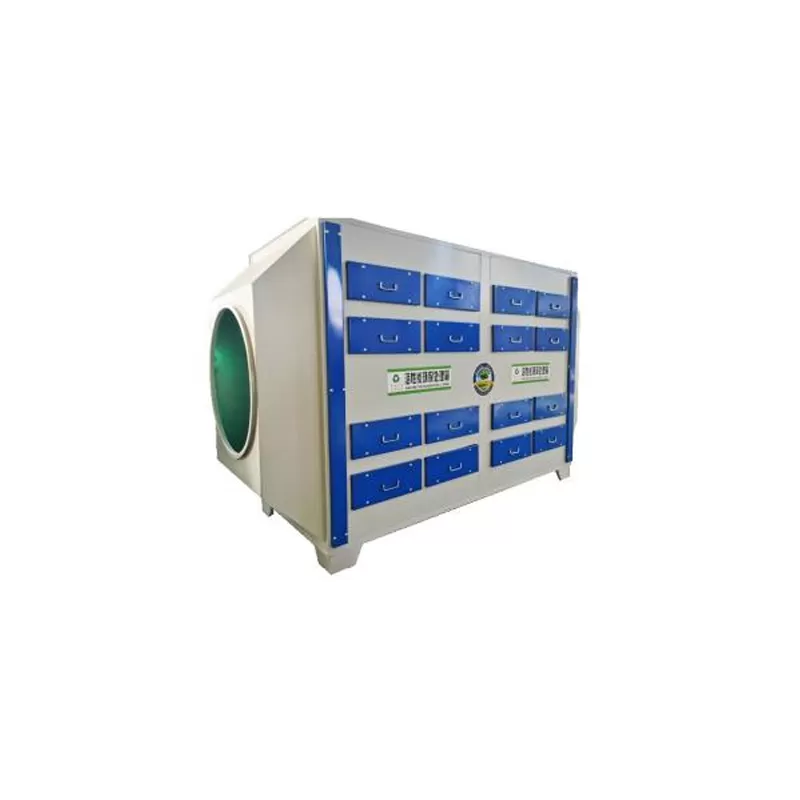

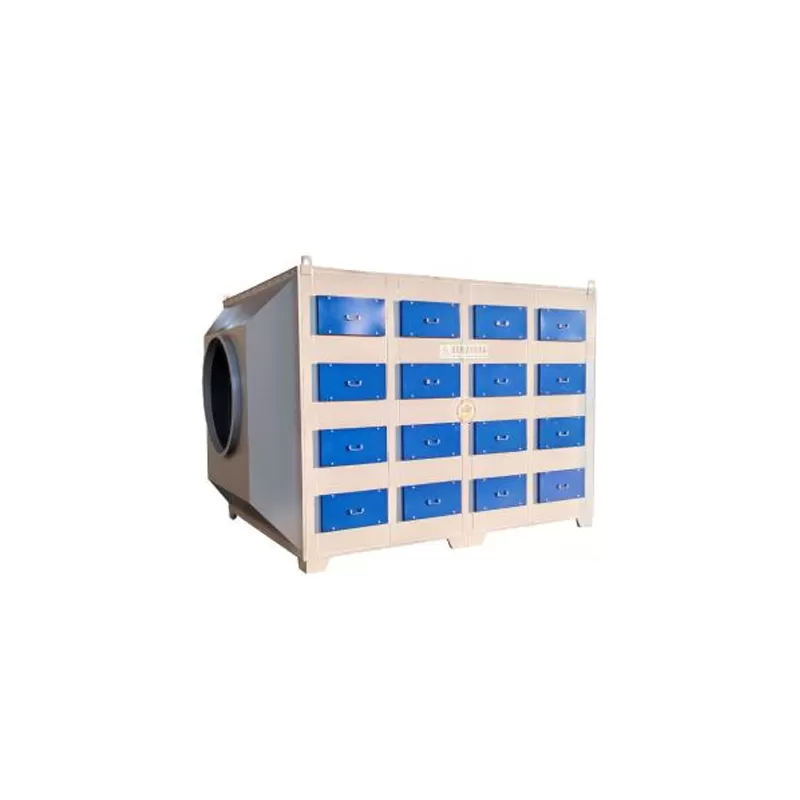

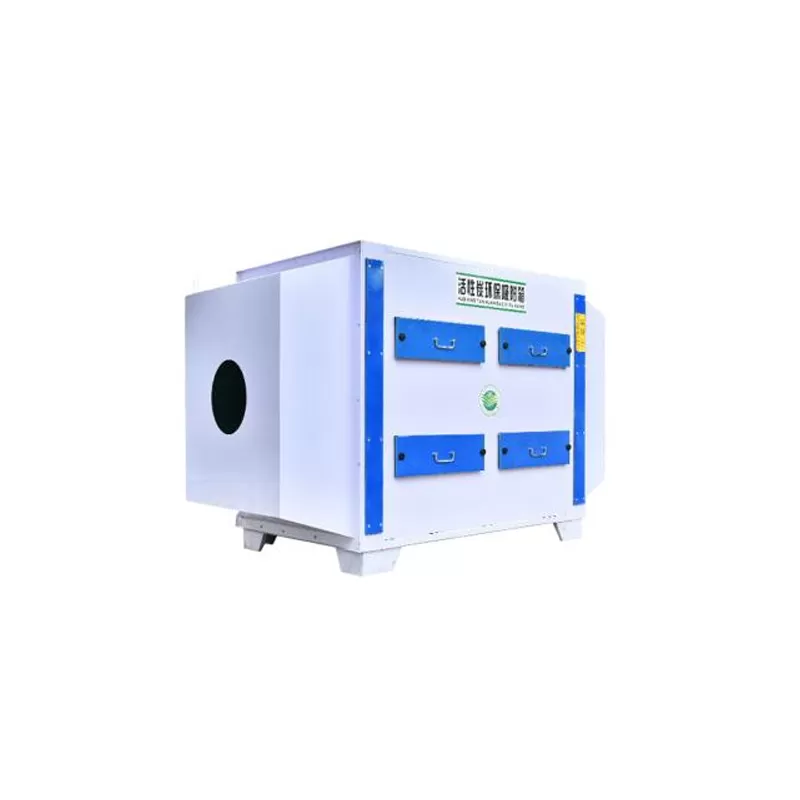

The Senotay Activated Carbon Adsorption Box: The Solution for Industrial Air Purification

Our Senotay’s Activated Carbon Adsorption Box is engineered for high-efficiency gas purification and continuous industrial operation. Compared to standard carbon filters. Tis systems features an optimized flow path, modular cartridge design and durable anti-corrosion construction that’s ensuring maximum adsorption efficiency and minimal downtime.

Our system provides stable performance even under high concentrations of exhaust gases that generally making it the ideal choice for demanding industries.

Types (Senotay AC Series)

Model Code | Box Size (mm) | Airflow Range (m³/h) | Adsorption Efficiency (%) | Static Pressure (Pa) | Noise (dB(A)) |

AC-800 | 800×600×1000 | 2,000–3,000 | 95 | 350 | 62 |

AC-1000 | 1000×800×1200 | 3,000–4,500 | 96 | 400 | 63 |

AC-1200 | 1200×1000×1300 | 4,000–6,000 | 97 | 450 | 65 |

AC-1500 | 1500×1000×1500 | 6,000–8,000 | 98 | 500 | 67 |

AC-1800 | 1800×1200×1600 | 8,000–10,000 | 98 | 550 | 68 |

AC-2000 | 2000×1200×1800 | 10,000–12,000 | 99 | 600 | 70 |

AC-2200 | 2200×1500×2000 | 12,000–14,000 | 99 | 650 | 71 |

AC-2500 | 2500×1500×2200 | 14,000–16,000 | 99 | 700 | 72 |

Technical Specifications & Expert Data (Senotay AC Series)

Parameter | 1,500 m³/h Model | 3,000 m³/h Model | 5,000 m³/h Model | 8,000 m³/h Model | 12,000 m³/h Model | 18,000 m³/h Model | 25,000 m³/h Model | 35,000 m³/h Model |

Airflow Capacity | 1,500 m³/h | 3,000 m³/h | 5,000 m³/h | 8,000 m³/h | 12,000 m³/h | 18,000 m³/h | 25,000 m³/h | 35,000 m³/h |

Carbon Bed Depth | 150 mm | 200 mm | 250 mm | 300 mm | 350 mm | 400 mm | 450 mm | 500 mm |

VOC Removal Efficiency | ≥90% | ≥92% | ≥93% | ≥94% | ≥95% | ≥95% | ≥95% | ≥95% |

Power Supply | 220V/1Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz |

Fan Power (kW) | 0.75 | 1.5 | 2.2 | 4.0 | 5.5 | 7.5 | 11.0 | 15.0 |

Dimensions (W×D×H, mm) | 800×600×1200 | 1000×800×1500 | 1200×900×1800 | 1500×1000×2000 | 1800×1200×2200 | 2000×1400×2400 | 2400×1600×2600 | 2800×1800×2800 |

Noise Level (dB) | ≤65 | ≤68 | ≤70 | ≤72 | ≤74 | ≤75 | ≤76 | ≤77 |

IP Rating | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 |

Operating Temp Range | -10°C to 60°C | -10°C to 60°C | -10°C to 60°C | -10°C to 60°C | -10°C to 60°C | -10°C to 60°C | -10°C to 60°C | -10°C to 60°C |

Warranty / Lead Time | 12 mo / 7 days | 12 mo / 10 days | 12 mo / 12 days | 12 mo / 15 days | 12 mo / 18 days | 12 mo / 20 days | 12 mo / 22 days | 12 mo / 25 days |

The Structure of an Activated Carbon Purifier Usually Includes the Following Main Parts:

Shell: It protects and supports the internal components and is generally made of solid materials such as plastic or metal.

Air inlet: Air enters the cleaner through the air inlet.

Filter: A primary filter may be used to filter larger particles and prevent the activated carbon from being blocked.

Activated carbon filter element: This is the core component, which is filled with a large number of activated carbon particles. Activated carbon particles have a rich pore structure and can absorb pollutants in the air.

Fan: It generates airflow and promotes air purification through the activated carbon filter element.

Air outlet: The purified air is discharged from the air outlet and returned to the indoor environment.

The Application Field of Activated Carbon Purifiers Is Relatively Wide, Mainly Including the Following Aspects:

Industrial production: It can be used in rubber factories, spraying factories, machinery processing factories, printing factories, furniture factories, foundries, and other industrial fields.

Office places, such as offices, conference rooms, office buildings, etc., can effectively remove odors, formaldehyde, and other pollutants in the air, create a more comfortable and fresh working environment, and improve employees' work efficiency and comfort.

Hospitals: Some special departments, such as operating rooms, wards, etc., can purify the air of bacteria, viruses, odors, etc., which helps reduce the risk of infection and protect the health of patients and medical staff.

Laboratories: In some chemical laboratories, biological laboratories, and other environments, harmful gases and odors generated during the experiment can be removed to ensure the safety of experimenters and the accuracy of experimental results.

Public places, such as hotel lobbies, shopping malls, cinemas, etc., can improve the air quality of public spaces and bring better experiences to customers and consumers.

In short, activated carbon purifiers are widely used to improve air quality and ensure people's healthy lives and work.

Key Features & Benefits

High Adsorption Efficiency: It can Removes up to 99% of harmful gases and odors.

Modular Cartridge Design: It is Easy to replace or expand for higher capacity.

Corrosion-Resistant Construction: The system Built to last in harsh industrial settings.

Low Maintenance: It’s Long service life reduces operating costs.

Eco-Friendly Operation: our product always Meets international environmental standards.

Ideal Applications for the Activated Carbon Adsorption Box

Our industrial activated carbon filter is engineered for demanding air purification tasks in:

Cement Plants.

Steel & Metal Fabrication.

Chemical Processing Facilities.

Paint & Coating Lines.

Food & Beverage Production.

Petrochemical and Refining Industries.

Case Study: Industrial VOC Control Success

A Singapore-based paint manufacturer reduced VOC emissions by 18% and extended filter life by 35% after switching to Senotay’s Activated Carbon Adsorption Box system.

Why Senotay is the World’s Trusted Activated Carbon Box Manufacturer

Our Manufacturing & Quality Advantage

At Hebei OuTai Environmental Protection Equipment Co., Ltd. we follow strict quality standards across design, production and testing. Our facility is ISO 9001:2015 certified and every adsorption box undergoes multi-stage inspection for air tightness, carbon saturation and coating integrity.

Global Support & Custom Engineering

Senotay offers custom-built filtration solutions to match your industry’s specific needs. With global logistics and local support teams, we ensure fast delivery, expert guidance and full technical documentation.

Frequently Asked Questions (FAQ)

Q.How long do Activated Carbon Adsorption Boxes last?

Answers:Typically 12–24 months, depending on gas concentration and operating conditions. Regular monitoring of carbon saturation ensures optimal performance.

Can Activated Carbon Adsorption Boxes handle high VOC concentrations? Answers:Yes,Senotay’s modular system is designed for continuous operation under high VOC loads with stable adsorption rates.

What is an Activated Carbon Adsorption Box also known as?

Answers: Also called industrial activated carbon filter, activated carbon purifier or activated carbon filtration unit.