What is 9-19 Industrial Blower?

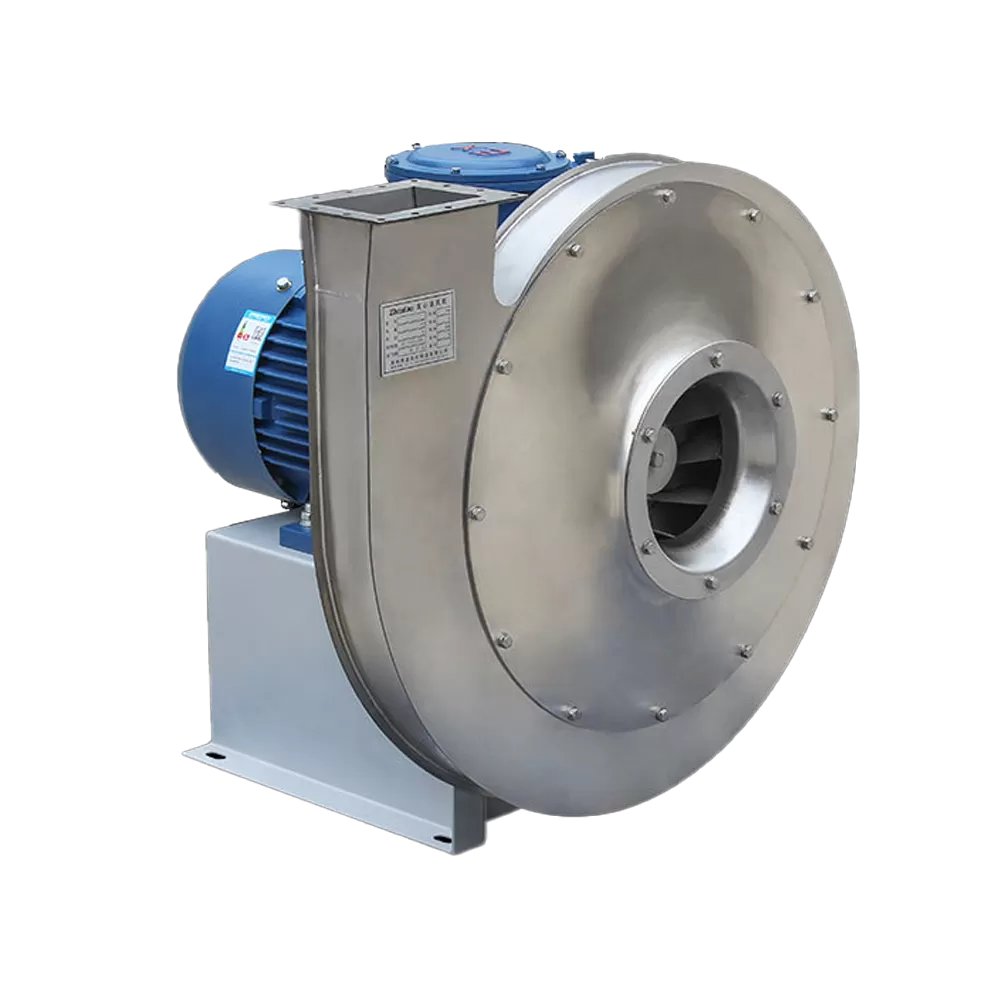

The 9-19 Industrial Blower particularly which is a high-efficiency centrifugal fan meticulously engineered to handle high-pressure, continuous airflow operations in industrial applications. Designed and manufactured by Senotay - Hebei OuTai Environmental Protection Equipment Co., Ltd. , this blower is commonly used as a boiler induced draft (ID) fan and forced draft (FD) blower for heavy-duty industrial systems.

Built on a time-tested 9-19 high-pressure blower platform, it ensures stable combustion, energy-efficient airflow, and long service life in extreme conditions up to 450°C, making it ideal for sectors such as metallurgy, cement, chemicals, power generation, dust extraction, and tunnel ventilation.

Why Choose the 9-19 Industrial Blower?

Choosing the 9-19 Industrial Blower means investing in performance reliability, energy efficiency, and customization flexibility. Senotay’s expertise as a 9-19 high pressure fan manufacturer ensures each unit is tailored to industry-specific needs, ensuring 95%+ operational availability and seamless integration with diverse draft and ventilation systems.

Key Reasons to Choose:

Exceptional Air Pressure Performance: Achieves up to 1,800 Pa static pressure, ensuring stable air delivery for combustion and dust removal systems.

High-Temperature Capability: Handles flue gas temperatures up to 450°C with robust sealing and cooling systems.

Customized Engineering: Available in direct, belt, or coupling drive configurations to fit specific boiler designs.

Durable Construction: Made with high-strength wear-resistant steel (Q355B) for enhanced durability and mechanical strength.

Global Standard Compliance: Certified under ISO 9001:2015 and CE, ensuring full international quality assurance.

Product Description, Material Properties & Standard Specifications

The 9-19 Industrial Blower delivers superior airflow power with motor capacities ranging from 2.2 kW to 90 kW, covering airflow volumes between 1,500 m³/h to 109,000 m³/h. Its impeller can be radial, backward-inclined, or forward-curved, optimizing performance across various resistance levels.

Material & Mechanical Properties

Component | Material | Property | Standard Compliance |

Housing / Casing | Q355B Steel | High tensile & anti-corrosion | EN 10025-6 / ISO 6506-1 |

Impeller | Alloy Steel | Dynamic balance & fatigue-resistant | ISO 1940 |

Shaft | 40CrNiMo7 | High torsion endurance | ISO 286-2 |

Bearings | NSK/SKF | High load & long-life lubrication | ISO 10816 |

Cooling Method | Forced liquid cooling | For high-temp applications | ISO 12953 |

Surface Coating | Epoxy coated finish | Corrosion & heat resistant | ASTM D4541 |

Types of 9-19 Industrial Blower

Model | Drive Type | Impeller Dia (mm) | Speed (RPM) | Airflow (m³/h) | Pressure (Pa) | Motor Power (kW) |

9-19-3.2A | Direct Drive | 320 | 2900 | 1,525–3,135 | 2,267–2,500 | 1.5–3.0 |

9-19-4A | Direct Drive | 400 | 2900 | 3,375–6,270 | 2,225–2,537 | 3.0–5.5 |

9-19-5A | Direct Drive | 500 | 2900 | 6,685–11,870 | 2,905–3,375 | 5.5–11.0 |

9-19-6C | Belt Drive | 630 | 1,450 | 17,550 | 4,325 | 22.0 |

9-19-8C | Belt Drive | 800 | 1,450 | 31,500–36,850 | 4,400–4,800 | 30.0–55.0 |

9-19-10D | Coupling Drive | 1,000 | 960 | 69,250 | 4,875 | 75.0 |

9-19-12D | Coupling Drive | 1,250 | 730 | 109,150 | 4,585 | 90.0 |

9-19-6 | Direct Drive | — | 1,450–2,900 | 1,500–13,500 | 800–1,800 | 2.2–11 |

9-19-10 | Direct Drive | — | 1,450–1,800 | 10,000–70,000 | 1,100–2,000 | 15–30 |

9-19-12 | Direct Drive | — | 1,450–1,800 | 30,000–85,000 | 1,200–2,200 | 30–75 |

9-19 Industrial Blower — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Overall Length: 980–1980 mm | Airflow Capacity: 1,500–42,800 m³/h | Q345 / 16Mn | 3–55 kW | 30,000–45,000 hrs |

Overall Width: 720–1580 mm | Total Pressure: 1,900–12,500 Pa | Carbon Steel (Q235) | 1450–2900 rpm | ISO 9001:2015 Certified |

Overall Height: 860–1720 mm | Operating Temp: ≤ 250°C | 40Cr Steel | ≤ 85 dB(A) | CE Certified |

Flange Diameter: Φ260–Φ620 mm | Max Temp (with cooling): 450°C | Graphite / High-Temp Seal Rings | Oil Bath / Grease | AMCA-Compliant Design |

(BCD): Φ220–Φ580 mm | Pressure Rating: 0.8–1.5 Bar | 4–12 mm | 210–980 kg | Every 3,000 hrs |

Mounting Hole: 4–12 Holes (Φ12–Φ22 mm) | Efficiency: 78–86% | High-Temp Epoxy (120–180 μm) | ≤ 4.5 mm/s | Unlimited / Continuous Duty

|

How Does a 9-19 Industrial Blower Work? (Working Mechanism)

The 9-19 blower operates on the centrifugal force principle.

Air Inlet: Air enters through the inlet at the center of the impeller.

Centrifugal Acceleration: As the impeller rotates, it accelerates the air radially outward.

Kinetic-to-Pressure Conversion: The increasing velocity converts kinetic energy into static pressure within the volute casing.

Outlet Flow: The compressed air is discharged through the outlet, ensuring consistent flow for combustion, ventilation, or material conveyance.

This design provides steady, balanced airflow even under varying pressures, making the 9-19 High Pressure Centrifugal Fan efficient and reliable for continuous operation.

Who Uses the 9-19 Industrial Blower?

Industries that rely on robust air management and energy efficiency depend heavily on this model:

Power & Energy Plants: As Boiler ID and FD fans for stable combustion air supply.

Metallurgy & Foundries: For furnace exhaust and heat treatment systems.

Chemical & Petrochemical Plants: To manage corrosive gases and particulates.

Cement & Mining Industries: Utilized in dust collection and air conveying systems.

Tunnels & Underground Mines: Used as industrial ventilation fans ensuring air purity.

Features of 9-19 Industrial Blower

High pressure capability up to 1,800 Pa

Operational temperature up to 450°C

Efficiency rating above 90%

ISO 9001 & CE certified build quality

Noise level below 75 dB(A)

Flexible mounting options: Direct, belt, or coupling drives

Long lifespan – up to 35,000 working hours with minimal maintenance

Core Components

Impeller: Aerodynamically optimized blades for balanced airflow.

Casing / Volute Housing: Designed to minimize energy loss and maximize pressure recovery.

Motor & Drive Options: Available in direct, belt, or coupling-drive methods.

Bearings & Shafting: Precision-aligned, vibration-free operation.

Inlet & Outlet Ducting: Smooth, resistance-free integration with system piping.

Sealing & Cooling Units: Dual mechanical seals and liquid-cooled housing for enhanced longevity.

Installation Method

The 9-19 Industrial Blower supports multiple installation configurations based on space and operating conditions:

Flange-mounted or Base-mounted setup for stable operation.

Horizontal or vertical alignment depending on duct direction.

Vibration isolation pads or anchors recommended for stability.

Motor Drive Alignment verified before commissioning to prevent wear.

Senotay provides on-site installation guidance and after-sales technical support for optimal system performance.

Technical Advantages in Senotay Manufacturing

Senotay (Hebei OuTai Environmental Protection Equipment Co., Ltd.) leverages decades of industrial fan design expertise, backed by ISO-certified production lines and AMCA-tested performance data.

Our Manufacturing Strengths:

Precision impeller balancing complying with ISO 1940 G6.3 standards.

Laser-cut steel fabrication ensures geometric accuracy.

CNC-machined casings for uniform air passage.

Dynamic vibration testing under ISO 10816-3 Class S0.

Comprehensive quality control throughout welding, assembling, and balancing.

FAQs – 9-19 Industrial Blower

Q1. What is the main application of the 9-19 High Pressure Centrifugal Fan?

Answers:It is primarily used as a Boiler Induced Draft (ID) Fan or Forced Draft (FD) Fan in boilers, kilns, and industrial ventilation systems.

Q2. What materials are used in Senotay’s 9-19 Industrial Blower?

Answers:We use Q355B high-strength steel, alloy impeller blades, and carbon steel shafts to ensure durability and reliability under high pressures and temperatures.

Q3. Can the blower be customized for special applications?

Answers:Yes, customization options include corrosion-resistant coatings, stainless steel structure, variable speed drives (VFD), and dual cooling circuits for higher temperature demands.

Q4. Is the 9-19 blower energy-efficient?

Answers:Absolutely. The blower achieves over 90% efficiency, reducing energy consumption in high-resistance environments.

Q5. What certifications does the 9-19 blower comply with?

Answers:It meets ISO 9001:2015, CE, and AMCA quality and safety standards.

Q6. What is the typical service life?

Answers:With proper maintenance, the service life exceeds 35,000 hours or about 5 years of continuous use.