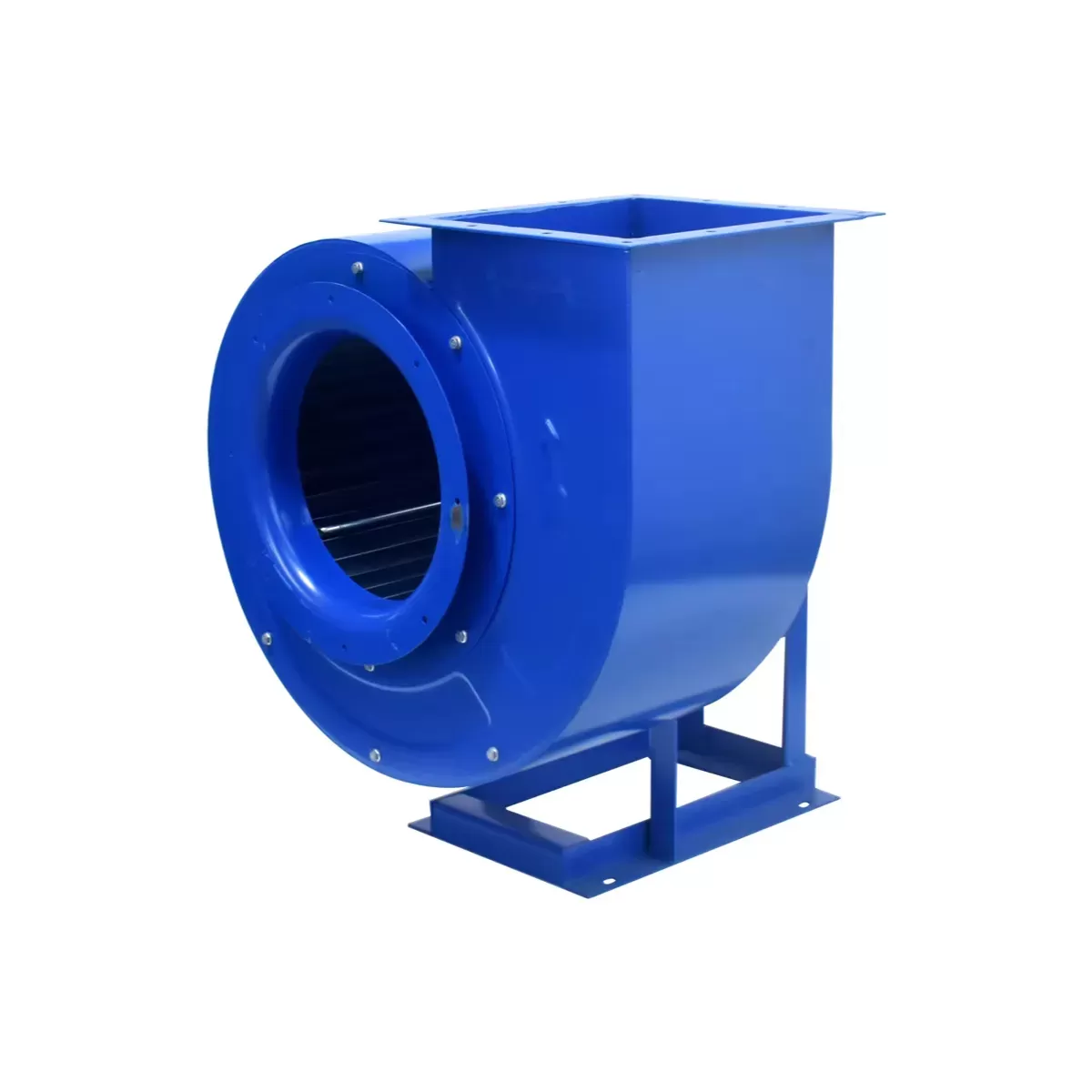

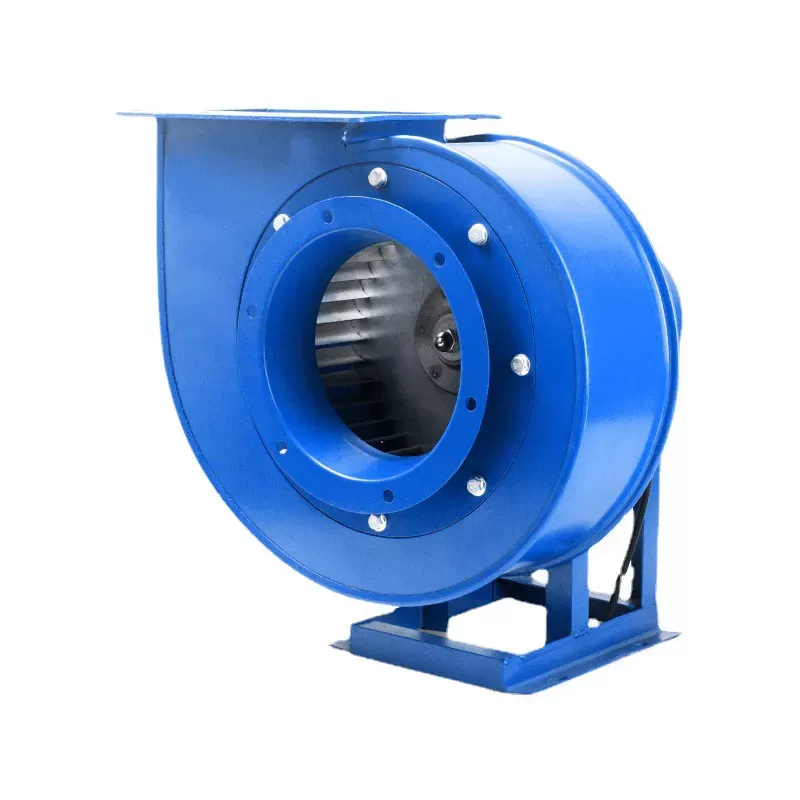

What is a 4-72 Industrial Blower?

The 4-72 industrial blower which is a standardized series of centrifugal fans designed for high efficiency and low noise industrial ventilation. This series industrial blower is Engineered to handle large volumes of air at low to medium static pressure and it serves as a reliable ai -moving solution for factories, boiler systems, HVAC applications and dust removal processes and in many more industries. This blower fan is flagship product from Senotay which known as Hebei OuTai Environmental Protection Equipment Co., Ltd. The manufacturer from china. This 4-72 model represents decades of R&D expertise with ensuring durability , high performance and environmental compliance.

The 4-72 series is also available in configurations such as 4-72-A and 4-72-C which is trusted worldwide for its adaptability including quiet operation and consistent airflow delivery.

Some Choosing reason for 4-72 Industrial Blower

Choosing a 4-72 centrifugal fan means investing in a product designed for efficiency, stability and long-term reliability. Here's some reason why industries prefer this model:

High Efficiency: It designer Aerodynamically is only for optimized impeller design for maximum airflow and minimal energy consumption.

Quiet Operation: The system is perfectly Balanced because of impellers and vibration free mounting reduce operational noise to a minimum.

Durable Construction: For better durability and make it live longer it is specially Made from premium carbon steel or stainless steel, with anti-oxidation coatings to prevent corrosion.

Versatile Applications: In industrial application it Performs excellently across chemical plant, cement industry, HVAC system and wastewater treatment facilities.

Standards Compliance: It fulfill your standard and it Produced under ISO 9001:2015 quality standards and carries CE certification which ensuring safety and export readiness.

Product Description & Material Properties

The 4-72 industrial air blower is composed of a high-strength steel body and dynamically balanced impeller and smooth airflow channels. It operates effectively under ambient temperatures up to 80°C and with optional cooling wheels where it can handle gases up to 200°C continuously.

Typical Material Composition:

Component | Material | Key Properties |

Casing | Carbon Steel / Stainless Steel | High tensile strength, oxidation resistance |

Impeller | Q235 / Stainless Steel | Strong rigidity, low vibration during operation |

Shaft | Alloy Steel | High fatigue strength and stability |

Bearings | Imported SKF / NSK | Low noise, long lifespan |

Coating | Anti-corrosive Spray | Enhanced surface protection against oxidation |

Standard Mechanical Properties:

4-72 Blower Model Specifications & Technical Comparison

Model | Speed (r/min) | Air Flow (m³/h) | Pressure (Pa) | Power (kW) | Drive Type | Efficiency (%) |

4-72-2.5A | 2900 | 805–1677 | 792–483 | 0.75–2.0 | Direct | 70% |

4-72-3.2A | 2900 | 1688–3517 | 1300–792 | 2.2 | Direct | 73% |

4-72-4A | 2900 | 4012–7419 | 2014–1320 | 5.5 | Direct | 75% |

4-72-4.5A | 2900 | 5712–10562 | 2554–1673 | 7.5 | Belt | 76% |

4-72-5A | 2900 | 7728–15445 | 3187–2019 | 15 | Belt | 78% |

4-72-6A | 1450 | 6677–13353 | 1139–724 | 4 | Belt | 80% |

4-72-6.3A | 1450 | 7729–15458 | 1256–798 | 7.5 | Coupling | 82% |

4-72-7.1A | 1450 | 12676–20513 | 1572–1168 | 11 | Coupling | 84% |

4-72-8D | 1450 | 15826–29344 | 2032–1490 | 18.5 | Coupling | 85% |

4-72-10D | 1450 | 40441–56605 | 3202–2532 | 55 | Coupling | 86% |

4-72 Industrial Blower — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Length: 980–1650 mm | Airflow Capacity: 1,200–48,000 m³/h | Q235 Steel | 180–260 Nm | 28,000–36,000 hrs |

Width: 740–1280 mm | Static Pressure: 380–1,850 Pa | Q345 Steel | 8 × Ø16 mm | 24–36 months |

Height: 860–1420 mm | Operating Pressure: 0.8–1.4 Bar | 45# Steel | 230–980 kg | ISO 9001 / CE |

Inlet Diameter: Φ250–Φ560 mm | Max Pressure: 1.6 Bar | Self-aligning Roller | 1.5–30 kW | > 12,000 cycles |

Outlet Flange: 220 × 320 mm | Operating Temp: -20 to 80°C | Nitrile Rubber (NBR) | 960–2900 rpm | > 90,000 cycles |

BCD: 350–450 mm | Max Temp: 120°C | 80–130 μm | ≤ 6.3 mm/s | 12–18 months |

Base Plate Thickness: 8–12 mm | Efficiency: ≥ 82% | GB/T 12467 Level 2 | 2 × Rated 1 Ton | Industrial Grade I |

4-72 Industrial Blower Working process

The working mechanism of the 4-72 centrifugal blower is based on centrifugal force. When the impeller rotates, air enters axially through the inlet and is pushed outward by the rotating blades. The motion converts mechanical energy from the motor into kinetic and pressure energy in the airflow. The volute then collects, directs, and discharges this energy as a uniform air stream.

Process Overview:

Air Inlet – First Air enters the impeller center.

Centrifugal Acceleration – Then The impeller imparts velocity and pressure to the air.

Air Discharge – And at end The volute transforms kinetic energy into pressure and disperses it through the outlet.

Features of the 4-72 Industrial Blower

Excellent Ventilation: For ventilation it is Optimized aerodynamic design ensures powerful air throughput.

Wide Applicability: Its really Suitable for non-corrosive, non-flammable air handling.

Low Noise Design: Dynamic balancing eliminates mechanical friction and noise.

Stable Operation: Minimal axial vibration and balanced motion.

Ease of Maintenance: Backward-curved impeller minimizes dust buildup.

Long Service Life: Rigid steel construction with protective coatings ensures durability.

Core Components

Component | Function |

Impeller | Provides kinetic energy to the air |

Volute Casing | Converts velocity into static pressure |

Shaft & Bearing System | Supports smooth rotation |

Motor | Drives the impeller |

Inlet Bell | Ensures laminar airflow |

Mounting Frame | Provides structural base |

Cleaning Door | Enables convenient maintenance |

Installation Method

The 4-72 centrifugal fan can be installed in multiple drive and rotation configurations based on operational needs:

Type A: Direct motor connection

Type B / C / E: Belt-driven connections

Type D / F: Coupling drive

Each configuration can be aligned in right-hand (CW) or left-hand (CCW) rotation, with outlet angles available in 0°, 45°, 90°, 135°, 180° and 225°.

Technical Advantages in Manufacturing at Senotay

As a leading industrial fan supplier in China, Senotay (Hebei OuTai Environmental Protection Equipment Co., Ltd.) integrates:

ISO 9001:2015 Certified Processes.

CE Machinery Safety Approved Designs.

Advanced Laser Cutting & CNC Balancing.

Imported Bearing and Motor Components.

Comprehensive In-House Testing Systems.

Every blower undergoes dynamic balancing verification, ensuring optimal stability and energy efficiency before shipment.

FAQs: 4-72 Industrial Blower

1. What is the airflow range of a 4-72 centrifugal fan?

Answers:Depending on the model, airflow ranges from 800 to over 56,000 m³/h.

2. What type of gases can it handle?

Answers:Only non-corrosive and non-flammable gases with dust levels below 150 mg/m³.

3. Can the blower be customized?

Answers:Yes. Senotay offers custom impeller sizes, materials (stainless steel, carbon steel), and mounting types for different industrial environments.

4. Is it suitable for high-temperature processes?

Answers:Yes, with a cooling wheel, it can operate up to 200°C continuously.

5. Do you offer after-sales support?

Answers:Absolutely. We provide installation guidance, technical support, and spare parts for long-term maintenance.

Why Partner with Senotay?

Located in Hebei Province, China, Senotay (Hebei OuTai Environmental Protection Equipment Co., Ltd.) is recognized as a trusted 4-72 blower manufacturer and industrial fan supplier in China. With advanced production capabilities, strict quality control, and a global customer base, we deliver premium-grade industrial centrifugal fans that perform reliably across all environments.