What is a 4-68 Industrial Blower?

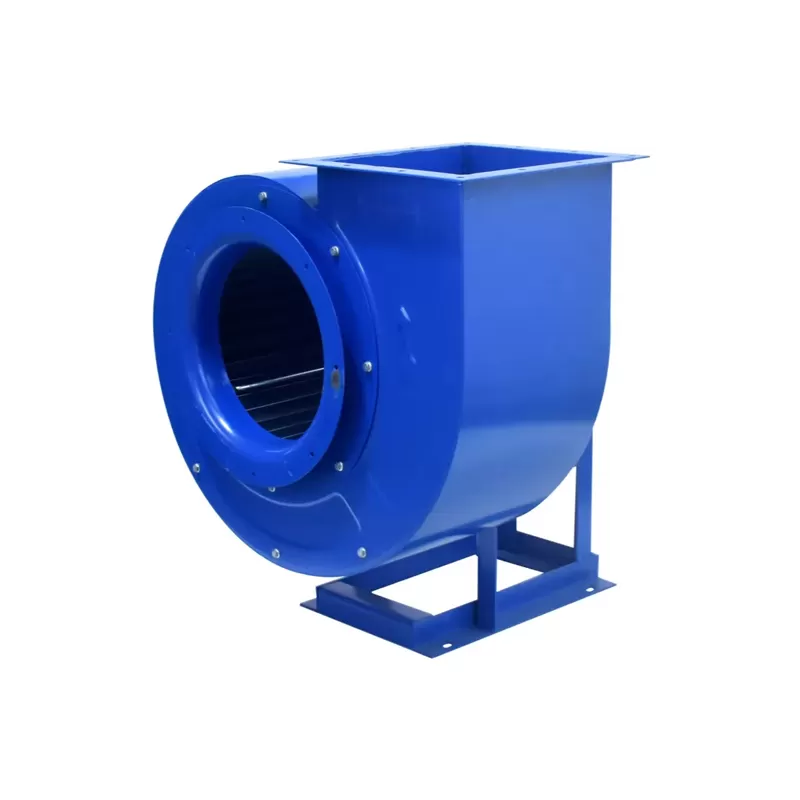

The 4-68 Industrial Blower which is a medium-pressure centrifugal fan.The blower fan is specifically engineered for industrial grade air movement applications. As part of HEBEIOUTAI ENVIRONMENTAL PROTECTION EQUIPMENT CO., LTD a chinese blower fan manufacturer provide AMCA certified blower series.This super performance fan delivers superior airflow and pressure which is ensuring efficient operation in various industrial environments such as factories, workshop, boiler houses and HVAC systems.

This series is built to meet stringent ISO 9001:2015 quality standards and the 4-68 centrifugal fan combines robust construction, energy efficiency and durable reliability. It is designed for handling clean air or gaseous mixtures with dust concentrations below 150 mg/m³ and temperatures up to approximately 80°C.

The reason for Choosing 4-68 Industrial Blower

Our 4-68 industrial blower is trusted globally for its consistent power, energy saving design and adaptable structure. Here some reason that why industries shpould trust on it:

Versatile Performance: Its performance supports a wide range of airflow is between 1,000–80,000 m³/h and pressure capacities upto 650–3,800 Pa which making it suitable for various processes.

High Efficiency and Low Noise: Its design Aerodynamic only to ensures high static efficiency with a quieter operation.

Heavy Duty Construction: For heavy duty comnstruction part the blower Precision balanced impeller including quality bearings and the reinforced steel housing ensure longevity even in demanding conditions.

Certified Safety: For certification the blower fan is certified with CE and AMCA certification standards for safety and reliability in industrial air systems.

Types of 4-68 Industrial Blower Model

Model | Transmission | Impeller Diameter (mm) | Speed (RPM) | Airflow Range (m³/h) | Pressure Range (Pa) | Motor Power (kW) |

4-68-2.8A | Direct Drive | 280 | 2900 | 1131–2262 | 657–971 | 0.55–2.0 |

4-68-3.2A | Direct Drive | 320 | 2900 | 1025–2135 | 1267–1500 | 0.75–2.2 |

4-68-3.55A | Direct Drive | 355 | 2900 | 2708–5013 | 1108–1608 | 3.0 |

4-68-4A | Direct Drive | 400 | 2900 | 2375–4270 | 1225–1537 | 2.2–4.0 |

4-68-5A | Direct Drive | 500 | 2900 | 4685–8370 | 1905–2375 | 4.0–7.5 |

4-68-6C | Belt Drive | 630 | 1450 | 12550 | 3325 | 15.0 |

4-68-8C | Belt Drive | 800 | 1450 | 22500–26850 | 3400–3800 | 22.0–37.0 |

4-68-10D | Coupling Drive | 1000 | 960 | 49250 | 3875 | 55.0 |

4-68-12D | Coupling Drive | 1250 | 730 | 79150 | 3585 | 90.0 |

4-68-14D | Coupling Drive | 1400 | 730 | 96000 | 4100 | 110.0 |

4-68 Industrial Blower — Technical Specification Table

Physical Dimensions | Performance Ratings | Material & Construction | Operational Data | Certifications & Lifecycle |

Length: 920–1580 mm | Airflow Capacity: 1,800–62,000 m³/h | Q235 Carbon Steel | 160–240 Nm | 26,000–34,000 hrs |

Width: 680–1320 mm | Static Pressure: 450–2,150 Pa | Q345 High-Strength Steel | 8–12 × Ø14–Ø18 mm | 24–36 months |

Height: 840–1460 mm | Operating Pressure: 0.8–1.5 Bar | 45# Steel | 210–890 kg | ISO 9001:2015 / CE / AMCA |

Inlet Diameter: Φ220–Φ600 mm | Max Pressure: 1.7 Bar | Spherical Roller Bearing | 1.5–37 kW | > 10,000 cycles |

Outlet Flange: 180 × 260 mm | Operating Temp: -20 to 80°C | NBR (Nitrile Rubber) | 960–2900 rpm | > 85,000 cycles |

BCD: 330–480 mm | Max Temp: 100°C | 70–120 μm | ≤ 6.3 mm/s | 12–18 months |

Base Plate Thickness: 6–12 mm | Efficiency: ≥ 80% | GB/T 12467 Level 2 | 2 × Rated 1 Ton | Industrial Grade I

|

Product Description & Material Properties

The 4-68 centrifugal fan series consists of multiple models with different impeller diameters, power ratings, and airflow capacities. Each unit is carefully designed for optimal aerodynamic performance and durability.

Material Options:

Standard: High-grade carbon steel (anti-wear and stable under high mechanical load)

Optional: Stainless steel or coated surfaces for enhanced corrosion and chemical resistance

Finish: Powder-coated, corrosion-resistant paint finish for long-term operation in industrial environments

Standard Mechanical Properties:

Property | Standard Value | Unit | Remarks |

Max Operating Temp | ≤ 80°C | — | Suitable for standard air systems |

Max Dust Content | ≤ 150 mg/m³ | — | Designed for clean/non-viscous air |

Bearing Type | Heavy-duty Ball Bearings | — | Long service life, low vibration |

Surface Protection | Electrostatic powder coating | — | Corrosion resistant |

Noise Level | <85 dB (A) | — | Under rated conditions |

Power Range | 0.55 kW – 90 kW | — | According to model |

4-68 Industrial Blower Working process

4-68 industrial blower operates on the centrifugal principle. Firstly from environment the Air enters axially into the impeller hub and where the rapidly rotating impeller blades accelerate the air radially outward. This velocity is then converted into static pressure within the scroll shaped housing which delivering uniform with high-pressure air output suitable for ventilation, exhaust and material conveying systems.

Key Mechanism Steps:

Inlet: here inside the Air enters through the center of the blower.

Impeller Action: The action happened because of kinetic energy is imparted by the impeller.

Energy Conversion: Here the Velocity is transformed into pressure via the volute casing.

Outlet: Highpressure air or gas exits through the discharge duct.

Industry that Use 4-68 Industrial Blower

This fan serves multiple industries, providing reliable airflow and ventilation solutions:

Power Plants: In power plant it is mainly use for flue gas handling and combustion draft..

Cement & Chemical Plants: Here it is widly use for dust extraction and particulate control.

Boiler Houses & Foundries: In boiler house It is use for air feeding and exhaust systems

Food & Beverage Plants: for drying, cooling and air movement

Features of 4-68 Industrial Blower

Wide range of airflow and speed configurations.

Precision-balanced impeller for vibration-free performance.

Energy-efficient motor options.

Low-maintenance and long service life.

Flexible drive selections (direct-coupled, belt-driven or coupling).

Compact design suitable for retrofitting existing systems.

Complies with AMCA and CE standards.

Core Components

Impeller / Fan Wheel: Aerodynamically designed and dynamically balanced to minimize noise and vibration.

Casing: Volute housing designed for optimal pressure recovery.

Drive System: Electric motor coupled directly or through belt/coupling.

Shaft & Bearings: High-precision components ensuring smooth operation.

Inlet & Outlet Ducts: Standard flanged design for easy installation.

Base Frame: Welded steel structure ensuring rigidity and stability.

Installation Method

Direct Drive: Motor shaft directly connected with the fan wheel—ideal for compact setups.

Belt Drive: Allows speed adjustment through pulley changes, suitable for systems requiring airflow control.

Coupling Drive: Robust and reliable for heavy industrial loads, ensuring minimal power loss.

Technical Advantages in Manufacturing (Senotay)

Manufactured by Hebei Outai Environmental Protection Equipment Co., Ltd. the 4-68 industrial blower is produced in a specialized facility with advanced CNC dynamic balancing, automated welding, and precision quality testing equipment.

Senotay’s Technical Edge:

AMCA-certified aerodynamic testing laboratory

Strict ISO 9001:2015 quality management system

3D modeling & CFD simulation for aerodynamic optimization

Efficient motor-pairing technology—higher CFM with lower kW consumption

Comprehensive after-sales support and custom design service

FAQs

1. What is the maximum operating temperature for the 4-68 centrifugal fan?

Answers:The standard model handles clean air or gas up to 80°C; customized high-temperature models are available on request.

2. Can the 4-68 blower handle corrosive gases?

Answers:Yes it can, By selecting stainless steel or anti-corrosion coating, it can safely manage mildly corrosive media.

3. What certifications does the 4-68 industrial blower have?

Answers:It is AMCA certified, CE compliant, and manufactured under ISO 9001:2015 quality management.

4. How do I select the right model?

Answers:Selection depends on required airflow (CFM), static pressure, application type and installation space and contact Senotay for design consultation.

5. Does Senotay provide customized solutions?

Answers:Absolutely yes it is . We offer tailored designs and OEM production for specific industrial ventilation and dust control systems.